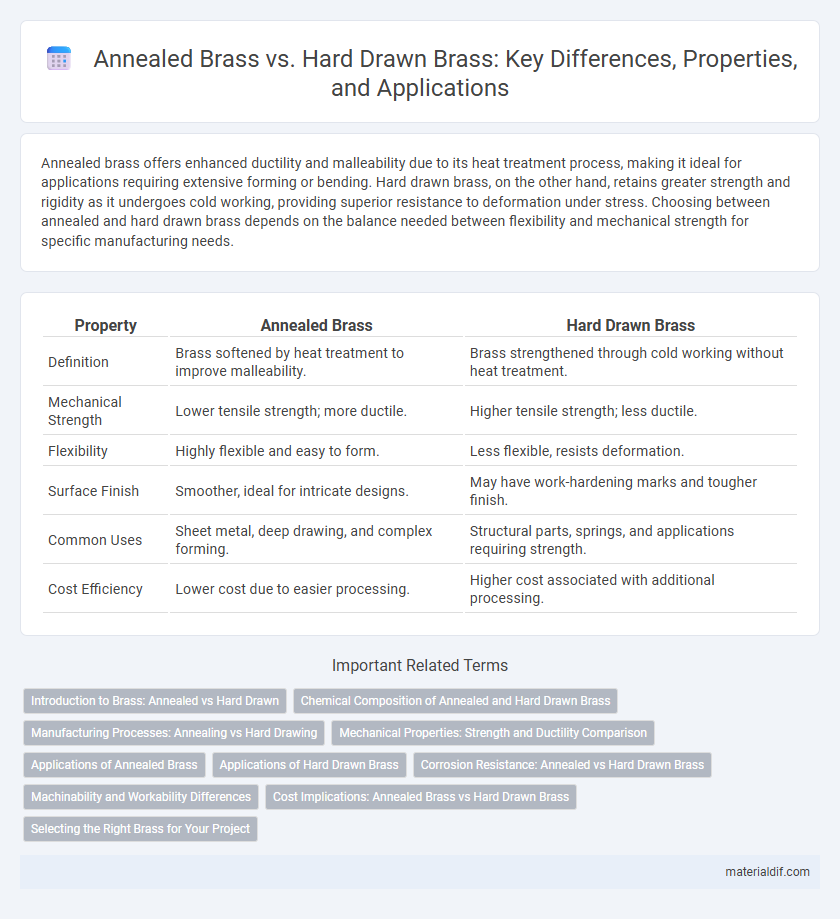

Annealed brass offers enhanced ductility and malleability due to its heat treatment process, making it ideal for applications requiring extensive forming or bending. Hard drawn brass, on the other hand, retains greater strength and rigidity as it undergoes cold working, providing superior resistance to deformation under stress. Choosing between annealed and hard drawn brass depends on the balance needed between flexibility and mechanical strength for specific manufacturing needs.

Table of Comparison

| Property | Annealed Brass | Hard Drawn Brass |

|---|---|---|

| Definition | Brass softened by heat treatment to improve malleability. | Brass strengthened through cold working without heat treatment. |

| Mechanical Strength | Lower tensile strength; more ductile. | Higher tensile strength; less ductile. |

| Flexibility | Highly flexible and easy to form. | Less flexible, resists deformation. |

| Surface Finish | Smoother, ideal for intricate designs. | May have work-hardening marks and tougher finish. |

| Common Uses | Sheet metal, deep drawing, and complex forming. | Structural parts, springs, and applications requiring strength. |

| Cost Efficiency | Lower cost due to easier processing. | Higher cost associated with additional processing. |

Introduction to Brass: Annealed vs Hard Drawn

Annealed brass undergoes a heat treatment process that softens the metal, enhancing its machinability and ductility for intricate shaping and forming tasks. Hard drawn brass is cold-worked through a drawing process, increasing its strength and hardness but reducing flexibility, making it suitable for structural applications requiring durability. Choosing between annealed and hard drawn brass depends on the specific mechanical properties needed, such as malleability versus tensile strength.

Chemical Composition of Annealed and Hard Drawn Brass

Annealed brass typically contains a balanced chemical composition with copper ranging from 60% to 70% and zinc making up the remainder, which allows for improved ductility and softness due to heat treatment. Hard drawn brass has a similar copper-zinc ratio but includes slight work hardening through mechanical processing, resulting in increased strength and reduced malleability without altering its basic chemical composition. Trace elements like lead or tin may be present in both types to enhance machinability or corrosion resistance, but the fundamental difference lies in their physical state rather than their chemical makeup.

Manufacturing Processes: Annealing vs Hard Drawing

Annealed brass undergoes a heat treatment process where the metal is heated to a specific temperature and then slowly cooled, resulting in increased ductility and reduced hardness, facilitating easier machining and forming. Hard drawn brass is produced by cold drawing the metal through a die, enhancing its strength and hardness due to strain hardening without the use of heat. The manufacturing process of annealing softens the brass, while hard drawing mechanically strengthens the material through deformation.

Mechanical Properties: Strength and Ductility Comparison

Annealed brass exhibits lower tensile strength but higher ductility, making it ideal for applications requiring extensive forming and bending without cracking. Hard drawn brass, conversely, possesses increased tensile strength and hardness due to strain hardening but reduced ductility, enhancing its resistance to deformation under mechanical stress. Understanding the trade-off between strength and ductility in annealed versus hard drawn brass is essential for selecting the appropriate material in manufacturing processes.

Applications of Annealed Brass

Annealed brass is widely used in applications requiring high formability and machinability, such as electrical connectors, plumbing fittings, and decorative hardware. Its softness and ductility make it ideal for precision stamping, deep drawing, and intricate shaping processes. Annealed brass also excels in environments demanding corrosion resistance and aesthetic appeal, commonly found in musical instruments and architectural components.

Applications of Hard Drawn Brass

Hard drawn brass exhibits superior strength and rigidity compared to annealed brass, making it ideal for applications requiring structural integrity under stress. It is widely used in precision components such as electrical fittings, musical instruments, and mechanical parts where dimensional stability and hardness are critical. Hard drawn brass also excels in automotive and plumbing industries due to its wear resistance and durability.

Corrosion Resistance: Annealed vs Hard Drawn Brass

Annealed brass exhibits superior corrosion resistance due to its softer, more ductile microstructure, which allows for better stress relief and a reduced likelihood of stress-induced corrosion. Hard drawn brass, being work-hardened, has increased tensile strength but is more susceptible to stress corrosion cracking under harsh environments. The enhanced corrosion resistance of annealed brass makes it preferable for marine and chemical applications where exposure to corrosive elements is frequent.

Machinability and Workability Differences

Annealed brass exhibits superior machinability due to its softened microstructure, allowing easier cutting and shaping without tool wear. Hard drawn brass, characterized by increased tensile strength and hardness, offers enhanced workability for structural applications but reduces machinability because of its tougher, strain-hardened surface. Selecting between annealed and hard drawn brass depends on whether priority lies in ease of machining or mechanical strength during metal forming processes.

Cost Implications: Annealed Brass vs Hard Drawn Brass

Annealed brass generally incurs higher costs due to the additional heat treatment process that enhances its ductility and machinability, making it ideal for complex forming operations. Hard drawn brass, with its increased strength and hardness from cold working, tends to be more cost-effective for applications requiring durability without extensive shaping. Choosing between annealed and hard drawn brass directly impacts manufacturing expenses, as annealed brass may reduce tool wear and processing time yet demands a higher initial investment.

Selecting the Right Brass for Your Project

Annealed brass exhibits enhanced ductility and malleability due to its heat treatment process, making it ideal for intricate bending and forming tasks in manufacturing. Hard drawn brass offers superior tensile strength and hardness, providing greater wear resistance for structural applications requiring durability. Selecting the right brass depends on balancing the need for flexibility versus mechanical strength to optimize performance and longevity in your specific project.

Annealed Brass vs Hard Drawn Brass Infographic

materialdif.com

materialdif.com