Annealed brass is softened through a heat treatment process that increases its ductility and makes it easier to shape or form, ideal for applications requiring extensive bending or machining. Tempered brass undergoes additional heat and cooling steps to enhance its strength and hardness, providing improved durability and resistance to wear in high-stress environments. Choosing between annealed and tempered brass depends on the balance needed between flexibility and mechanical strength for specific industrial or decorative uses.

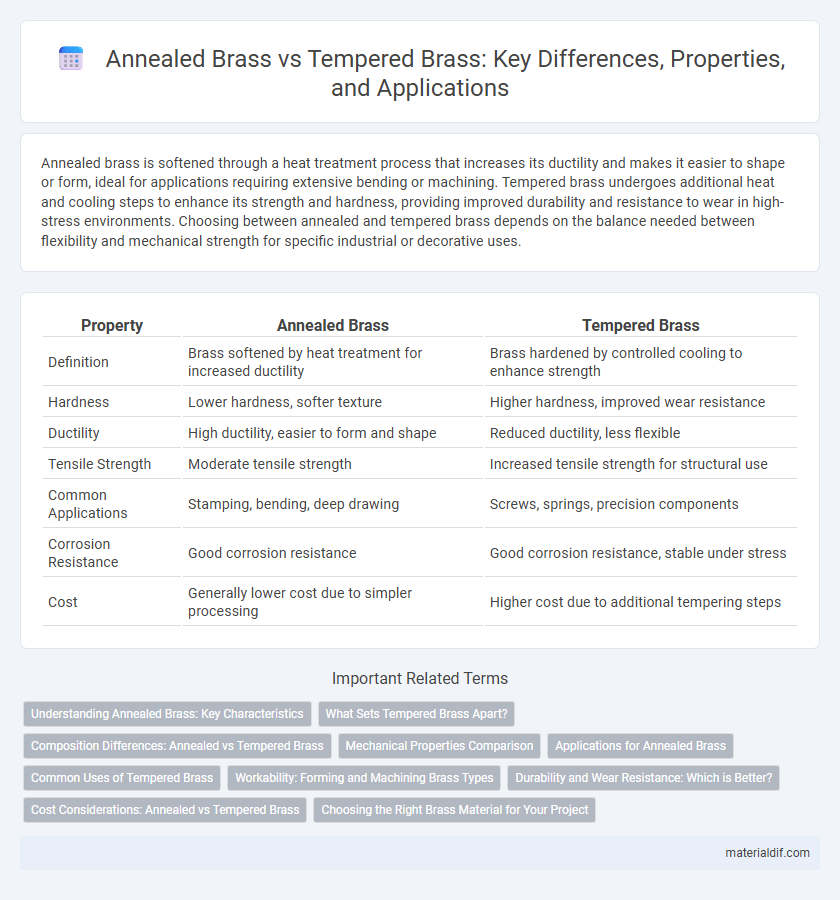

Table of Comparison

| Property | Annealed Brass | Tempered Brass |

|---|---|---|

| Definition | Brass softened by heat treatment for increased ductility | Brass hardened by controlled cooling to enhance strength |

| Hardness | Lower hardness, softer texture | Higher hardness, improved wear resistance |

| Ductility | High ductility, easier to form and shape | Reduced ductility, less flexible |

| Tensile Strength | Moderate tensile strength | Increased tensile strength for structural use |

| Common Applications | Stamping, bending, deep drawing | Screws, springs, precision components |

| Corrosion Resistance | Good corrosion resistance | Good corrosion resistance, stable under stress |

| Cost | Generally lower cost due to simpler processing | Higher cost due to additional tempering steps |

Understanding Annealed Brass: Key Characteristics

Annealed brass exhibits enhanced malleability and ductility due to its heat treatment process, which relieves internal stresses and softens the metal. This property makes annealed brass ideal for applications requiring intricate shaping or forming, such as in decorative hardware and tubing. In contrast to tempered brass, annealed brass offers superior workability but lower strength and hardness.

What Sets Tempered Brass Apart?

Tempered brass is distinguished by its enhanced mechanical strength and improved hardness compared to annealed brass, achieved through controlled heat treatment processes. This heat treatment refines the grain structure, resulting in increased durability and resistance to wear and deformation under stress. The superior tensile strength and dimensional stability of tempered brass make it ideal for applications requiring robust performance and long-term reliability.

Composition Differences: Annealed vs Tempered Brass

Annealed brass features a higher copper content, typically around 60-70%, combined with zinc to enhance ductility and softness, making it ideal for forming and machining. Tempered brass, on the other hand, contains a slightly altered composition with increased zinc or additional elements like tin or lead to improve strength and hardness through heat treatment. These compositional variations directly influence the mechanical properties and suitability of annealed versus tempered brass for specific industrial applications.

Mechanical Properties Comparison

Annealed brass exhibits lower hardness and higher ductility, making it easier to form and shape, with a typical tensile strength around 40,000 psi. Tempered brass undergoes heat treatment to increase hardness and tensile strength, often reaching up to 70,000 psi, providing improved resistance to wear and deformation. The mechanical properties of tempered brass make it suitable for applications requiring enhanced durability, while annealed brass is preferred for processes needing flexibility and ease of machining.

Applications for Annealed Brass

Annealed brass, characterized by its softened, ductile structure achieved through heat treatment, is widely used in applications requiring easy forming and high malleability, such as plumbing fittings, electrical connectors, and decorative hardware. Its enhanced workability makes it ideal for deep drawing, bending, and stamping processes in manufacturing industries. The material's corrosion resistance and conductivity further support its use in marine environments and electrical components.

Common Uses of Tempered Brass

Tempered brass is commonly used in applications requiring enhanced strength and durability, such as marine hardware, firearms components, and electrical connectors due to its resistance to fatigue and stress. Its increased hardness compared to annealed brass makes it ideal for mechanical parts, valves, and fittings that endure high pressure and wear. The ability of tempered brass to maintain dimensional stability under stress ensures reliable performance in industrial and automotive equipment.

Workability: Forming and Machining Brass Types

Annealed brass offers superior workability due to its softened structure, making it ideal for forming processes such as bending, drawing, and shaping with minimal risk of cracking. Tempered brass, hardened through heat treatment or cold working, provides enhanced strength but reduces machinability and formability, often necessitating specialized tools for cutting and shaping. When choosing between annealed and tempered brass, selecting annealed brass is preferred for intricate forming, while tempered brass suits applications requiring durability and wear resistance.

Durability and Wear Resistance: Which is Better?

Annealed brass undergoes a heat treatment process that softens the metal, enhancing its ductility but reducing durability and wear resistance compared to tempered brass. Tempered brass is strengthened through controlled cooling, resulting in higher hardness and superior resistance to wear and mechanical stress. For applications demanding long-term durability and wear resistance, tempered brass is the better choice due to its enhanced structural integrity.

Cost Considerations: Annealed vs Tempered Brass

Annealed brass generally costs less due to its softer, more malleable nature requiring less intensive processing than tempered brass. Tempered brass, hardened through heat treatment and strain, demands higher manufacturing expenses but offers increased strength and durability. Selecting between annealed and tempered brass depends on balancing budget constraints with performance requirements in specific applications.

Choosing the Right Brass Material for Your Project

Annealed brass offers enhanced malleability and ease of machining due to its softened state, making it ideal for intricate shapes and deep drawing applications. Tempered brass, with its increased strength and hardness from work hardening, provides superior durability and resistance to wear, suitable for structural components and high-stress environments. Selecting the right brass material hinges on balancing the need for formability with mechanical performance requirements specific to your project scope.

Annealed Brass vs Tempered Brass Infographic

materialdif.com

materialdif.com