Annealed brass is softened through a heat treatment process that increases its ductility and makes it easier to shape or machine, while work-hardened brass becomes stronger and more brittle due to strain hardening from mechanical deformation. The choice between annealed brass and work-hardened brass depends on the specific application requirements, with annealed brass preferred for forming and fabrication and work-hardened brass suited for structural uses requiring higher strength. Understanding the differences in mechanical properties helps optimize brass performance in manufacturing and industrial applications.

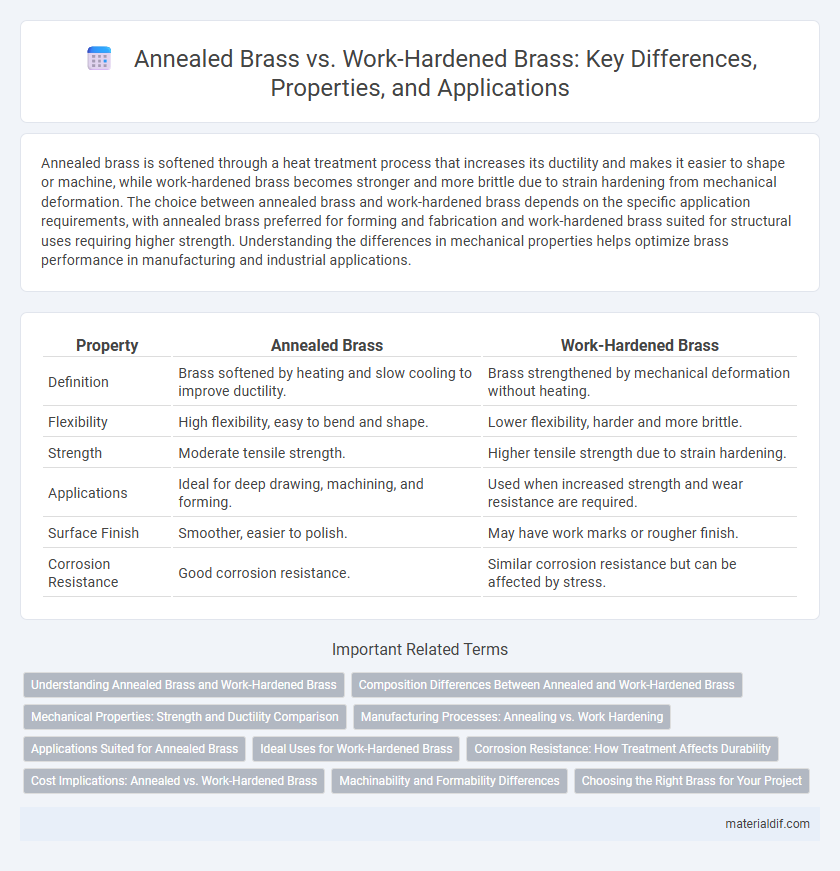

Table of Comparison

| Property | Annealed Brass | Work-Hardened Brass |

|---|---|---|

| Definition | Brass softened by heating and slow cooling to improve ductility. | Brass strengthened by mechanical deformation without heating. |

| Flexibility | High flexibility, easy to bend and shape. | Lower flexibility, harder and more brittle. |

| Strength | Moderate tensile strength. | Higher tensile strength due to strain hardening. |

| Applications | Ideal for deep drawing, machining, and forming. | Used when increased strength and wear resistance are required. |

| Surface Finish | Smoother, easier to polish. | May have work marks or rougher finish. |

| Corrosion Resistance | Good corrosion resistance. | Similar corrosion resistance but can be affected by stress. |

Understanding Annealed Brass and Work-Hardened Brass

Annealed brass is a type of brass that has been heat-treated to increase its ductility and reduce hardness, making it easier to shape and form in manufacturing processes. Work-hardened brass, on the other hand, becomes stronger and more rigid through mechanical deformation, which increases its tensile strength but decreases its malleability. Understanding the difference between these two states of brass is crucial for selecting the appropriate material based on the desired balance of flexibility and strength in various industrial applications.

Composition Differences Between Annealed and Work-Hardened Brass

Annealed brass undergoes a heat treatment process that restores its ductility by relieving internal stresses, resulting in a softer, more malleable alloy primarily composed of copper and zinc in specific ratios. Work-hardened brass, however, is mechanically deformed without heat treatment, increasing its strength and hardness due to strain-induced dislocation density within the same copper-zinc matrix. The key compositional difference lies in the microstructural changes caused by thermal annealing versus mechanical work hardening, affecting the alloy's mechanical properties without altering its fundamental elemental composition.

Mechanical Properties: Strength and Ductility Comparison

Annealed brass exhibits lower tensile strength but higher ductility compared to work-hardened brass, making it more malleable for forming operations. Work-hardened brass increases strength through strain hardening, resulting in reduced ductility and improved wear resistance. The trade-off between strength and ductility in these states influences their suitability for applications requiring flexibility or mechanical durability.

Manufacturing Processes: Annealing vs. Work Hardening

Annealed brass undergoes a controlled heating process that softens the metal, enhancing its ductility and making it easier to shape during manufacturing. Work-hardened brass is produced by mechanically deforming the alloy, which increases its strength and hardness but reduces its malleability. The annealing process involves heating brass to a specific temperature followed by slow cooling, whereas work hardening results from repeated bending, hammering, or rolling without additional heat.

Applications Suited for Annealed Brass

Annealed brass, characterized by its enhanced softness and improved ductility due to the annealing heat treatment, is ideally suited for applications requiring extensive forming, bending, or machining, such as intricate components in musical instruments, electrical connectors, and decorative hardware. This strain-relieved brass material allows for precise shaping without cracking or deformation, making it essential in manufacturing processes demanding high malleability. Industries that prioritize fabrication versatility and fine detailing often select annealed brass for producing custom fittings and ornate architectural elements.

Ideal Uses for Work-Hardened Brass

Work-hardened brass is ideal for applications requiring enhanced strength and durability, such as mechanical components, fittings, and fasteners where resistance to deformation is critical. Its increased hardness from cold working makes it suitable for use in locking mechanisms and precision instruments that demand wear resistance and dimensional stability. Unlike annealed brass, work-hardened brass offers improved load-bearing capacity without the need for additional heat treatment.

Corrosion Resistance: How Treatment Affects Durability

Annealed brass exhibits superior corrosion resistance due to its reduced internal stresses and more uniform grain structure achieved through heat treatment. Work-hardened brass, while mechanically stronger, contains higher residual stresses that can create microscopic sites prone to corrosion initiation. Consequently, annealed brass demonstrates enhanced durability in harsh environments compared to its work-hardened counterpart.

Cost Implications: Annealed vs. Work-Hardened Brass

Annealed brass typically incurs higher initial costs due to the additional heat treatment process that enhances its machinability and ductility, reducing tool wear and minimizing production downtime. Work-hardened brass, while generally less expensive upfront, can lead to increased expenses over time because its hardened state demands more robust tooling and can cause faster equipment wear. Considering total cost of ownership, annealed brass often provides better economic efficiency in manufacturing environments requiring extensive forming or machining operations.

Machinability and Formability Differences

Annealed brass exhibits superior formability due to its softened crystalline structure, allowing for easier shaping and bending without cracking. Work-hardened brass, having undergone strain hardening, offers enhanced machinability but reduced ductility, making it more suitable for precise cutting and threading operations. The balance between annealed and work-hardened brass depends on the specific requirements for flexibility versus dimensional accuracy in manufacturing processes.

Choosing the Right Brass for Your Project

Annealed brass offers enhanced ductility and ease of machining, making it ideal for intricate projects requiring extensive forming or bending. Work-hardened brass provides increased strength and wear resistance due to strain hardening, suitable for components subjected to mechanical stress or frequent handling. Selecting the right brass involves balancing flexibility and durability based on the specific functional and aesthetic demands of your project.

Annealed Brass vs Work-Hardened Brass Infographic

materialdif.com

materialdif.com