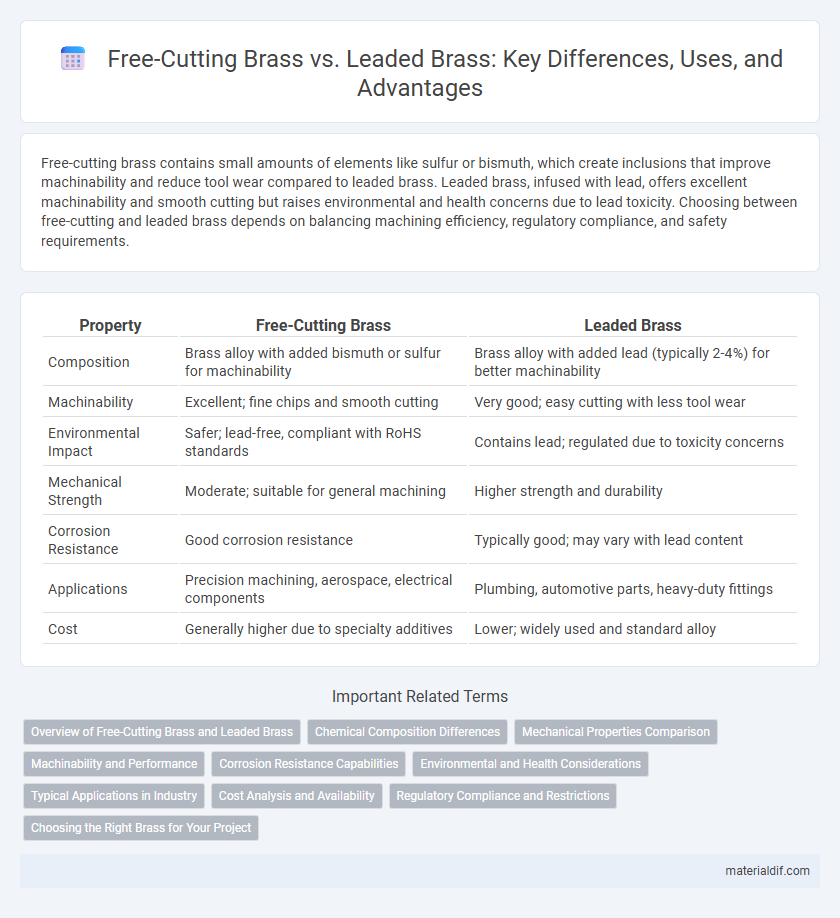

Free-cutting brass contains small amounts of elements like sulfur or bismuth, which create inclusions that improve machinability and reduce tool wear compared to leaded brass. Leaded brass, infused with lead, offers excellent machinability and smooth cutting but raises environmental and health concerns due to lead toxicity. Choosing between free-cutting and leaded brass depends on balancing machining efficiency, regulatory compliance, and safety requirements.

Table of Comparison

| Property | Free-Cutting Brass | Leaded Brass |

|---|---|---|

| Composition | Brass alloy with added bismuth or sulfur for machinability | Brass alloy with added lead (typically 2-4%) for better machinability |

| Machinability | Excellent; fine chips and smooth cutting | Very good; easy cutting with less tool wear |

| Environmental Impact | Safer; lead-free, compliant with RoHS standards | Contains lead; regulated due to toxicity concerns |

| Mechanical Strength | Moderate; suitable for general machining | Higher strength and durability |

| Corrosion Resistance | Good corrosion resistance | Typically good; may vary with lead content |

| Applications | Precision machining, aerospace, electrical components | Plumbing, automotive parts, heavy-duty fittings |

| Cost | Generally higher due to specialty additives | Lower; widely used and standard alloy |

Overview of Free-Cutting Brass and Leaded Brass

Free-cutting brass contains added elements such as lead, bismuth, or sulfur to enhance machinability and reduce tool wear, making it ideal for precision components in automotive and electrical industries. Leaded brass specifically includes lead, typically around 2-4%, to improve chip formation and surface finish during machining, but it raises environmental and health concerns due to lead content. Both materials offer excellent machinability, but free-cutting brass variants provide options with reduced lead or alternative additives to meet stricter regulations and sustainability goals.

Chemical Composition Differences

Free-cutting brass contains higher levels of lead, typically around 2-3%, enhancing machinability and reducing tool wear, whereas leaded brass has lower lead content, usually below 1.5%, which improves mechanical strength but decreases ease of machining. The primary alloying elements in both types include copper and zinc, with free-cutting brass often maintaining a copper content near 58-62% and zinc around 37-39%. Trace elements such as iron, manganese, and tin may be present in small quantities to adjust properties, but the significant difference lies in the lead content influencing machining performance and structural characteristics.

Mechanical Properties Comparison

Free-cutting brass exhibits superior machinability due to its higher lead content, allowing faster cutting speeds and reduced tool wear compared to leaded brass. Leaded brass typically offers enhanced tensile strength and improved corrosion resistance, making it suitable for structural applications requiring durability. The trade-off between machinability in free-cutting brass and mechanical strength in leaded brass determines their optimal industrial uses.

Machinability and Performance

Free-cutting brass typically contains higher lead content, enhancing machinability by reducing tool wear and enabling faster cutting speeds, making it ideal for complex, high-volume manufacturing. Leaded brass offers good machinability but may produce less smooth finishes and wear tools faster due to lower lead percentages. Performance-wise, free-cutting brass excels in precision components requiring tight tolerances, while leaded brass provides durability in applications where mechanical strength outweighs ease of machining.

Corrosion Resistance Capabilities

Free-cutting brass exhibits enhanced machinability due to added elements like sulfur but generally offers lower corrosion resistance compared to leaded brass, which contains lead to improve both machinability and resistance to corrosive environments. Leaded brass provides superior protection against dezincification and stress corrosion cracking, making it more suitable for plumbing and marine applications where exposure to moisture and corrosive agents is frequent. The choice between free-cutting and leaded brass depends on application-specific requirements balancing ease of manufacturing and long-term durability in corrosive conditions.

Environmental and Health Considerations

Free-cutting brass reduces environmental and health risks by eliminating lead content, a toxic heavy metal linked to neurological and reproductive issues. Leaded brass, commonly used for its machinability, poses disposal and recycling challenges due to lead contamination. Switching to free-cutting brass supports safer manufacturing processes and complies with stricter environmental regulations on hazardous substances.

Typical Applications in Industry

Free-cutting brass is widely used in precision machining applications due to its excellent machinability and minimal tool wear, making it ideal for manufacturing fasteners, gears, and intricate components in the automotive and electronics industries. Leaded brass, containing higher lead content, provides superior machinability but is favored in applications requiring enhanced strength and corrosion resistance, such as plumbing fittings, valve components, and marine hardware. Both alloys are essential in industrial production, with free-cutting brass preferred for high-speed, high-volume machining, and leaded brass chosen for durability-critical parts.

Cost Analysis and Availability

Free-cutting brass typically costs more than leaded brass due to its specialized alloy composition designed for improved machinability and reduced tool wear. Leaded brass remains more widely available and economical, benefiting from established manufacturing processes and broader supplier networks. Evaluating total production expenses reveals that free-cutting brass may lower machining costs despite higher raw material prices, while leaded brass offers competitive upfront purchasing advantages.

Regulatory Compliance and Restrictions

Free-cutting brass typically contains zinc and small amounts of other elements but excludes lead, aligning with strict regulatory compliance such as RoHS and REACH directives that restrict hazardous substances to ensure environmental and human safety. Leaded brass, while offering superior machinability due to lead content, faces increasing restrictions and phase-outs in many regions due to lead's toxicity and health risks, impacting its use in consumer products and plumbing applications. Manufacturers are shifting towards free-cutting alloys to meet evolving regulations and market demands for safer, sustainable materials.

Choosing the Right Brass for Your Project

Free-cutting brass offers superior machinability due to its higher lead content, making it ideal for projects requiring intricate machining and fast production. Leaded brass provides enhanced strength and corrosion resistance, suitable for structural components and applications exposed to harsh environments. Choosing the right brass depends on balancing the need for ease of machining against mechanical properties and environmental durability.

Free-Cutting Brass vs Leaded Brass Infographic

materialdif.com

materialdif.com