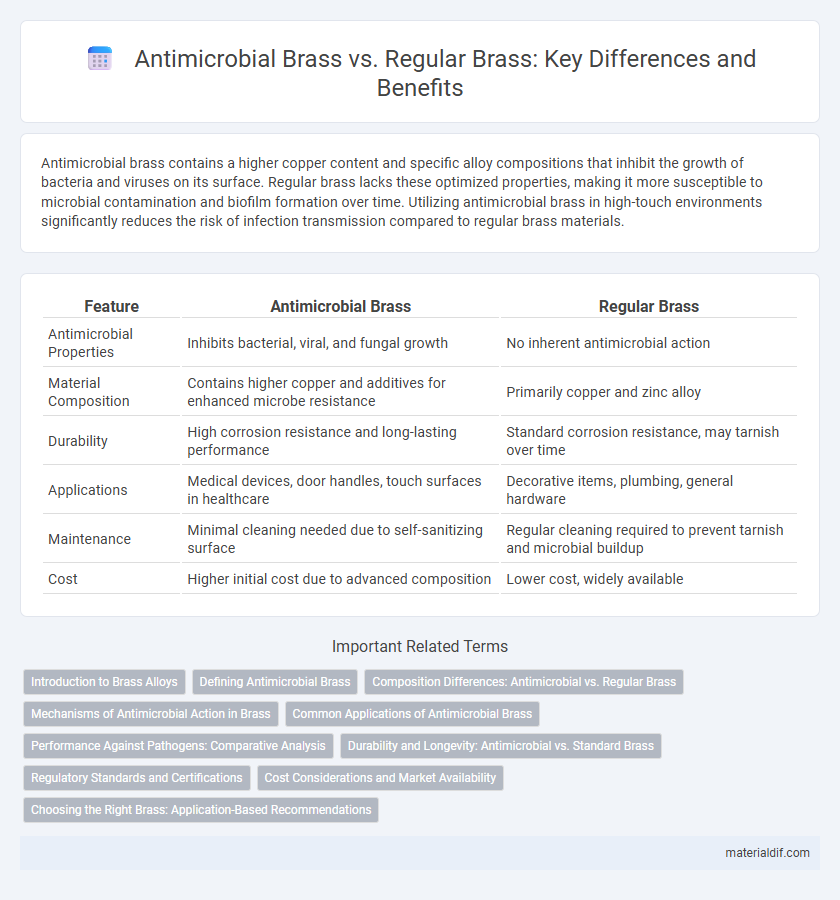

Antimicrobial brass contains a higher copper content and specific alloy compositions that inhibit the growth of bacteria and viruses on its surface. Regular brass lacks these optimized properties, making it more susceptible to microbial contamination and biofilm formation over time. Utilizing antimicrobial brass in high-touch environments significantly reduces the risk of infection transmission compared to regular brass materials.

Table of Comparison

| Feature | Antimicrobial Brass | Regular Brass |

|---|---|---|

| Antimicrobial Properties | Inhibits bacterial, viral, and fungal growth | No inherent antimicrobial action |

| Material Composition | Contains higher copper and additives for enhanced microbe resistance | Primarily copper and zinc alloy |

| Durability | High corrosion resistance and long-lasting performance | Standard corrosion resistance, may tarnish over time |

| Applications | Medical devices, door handles, touch surfaces in healthcare | Decorative items, plumbing, general hardware |

| Maintenance | Minimal cleaning needed due to self-sanitizing surface | Regular cleaning required to prevent tarnish and microbial buildup |

| Cost | Higher initial cost due to advanced composition | Lower cost, widely available |

Introduction to Brass Alloys

Brass, an alloy primarily composed of copper and zinc, exhibits varied antimicrobial properties depending on its composition. Antimicrobial brass contains higher copper content or incorporates antimicrobial metals like silver to inhibit microbial growth effectively. Regular brass, while offering durability and corrosion resistance, lacks the enhanced antimicrobial benefits found in specialized brass alloys designed for hygienic applications.

Defining Antimicrobial Brass

Antimicrobial brass is a specially engineered alloy infused with metals such as copper and silver that inhibit the growth of bacteria and other harmful microorganisms on its surface. This type of brass provides enhanced hygiene benefits, making it ideal for healthcare, food processing, and high-touch public environments. Regular brass lacks these antimicrobial properties, making it more susceptible to harboring bacteria and reducing overall surface cleanliness.

Composition Differences: Antimicrobial vs. Regular Brass

Antimicrobial brass contains a specific blend of copper and zinc, often with added elements such as silver or tin, to enhance its ability to kill bacteria on contact, while regular brass typically consists of a standard copper-zinc alloy without these antimicrobial additives. The copper content in antimicrobial brass is usually higher, as copper ions are responsible for disrupting microbial cell membranes and preventing growth. These compositional differences directly impact the material's effectiveness in hygiene-critical applications such as healthcare and public facilities.

Mechanisms of Antimicrobial Action in Brass

Antimicrobial brass leverages the release of copper and zinc ions, which disrupt bacterial cell membranes and interfere with vital enzymatic processes, leading to rapid microbial inactivation. Regular brass lacks the optimized alloy composition, resulting in significantly lower ion release and diminished antimicrobial efficacy. The enhanced ion release in antimicrobial brass creates an inhospitable environment for bacteria, reducing surface contamination and the risk of infection transmission.

Common Applications of Antimicrobial Brass

Antimicrobial brass is widely used in high-touch surfaces such as door handles, hospital fixtures, and public transportation handrails to reduce the spread of harmful microbes. Its copper content continuously inhibits bacterial growth, making it ideal for healthcare settings, food processing equipment, and water fittings. Regular brass lacks this prolonged antimicrobial effect, limiting its use in environments requiring stringent hygiene control.

Performance Against Pathogens: Comparative Analysis

Antimicrobial brass contains a higher copper content and specially formulated alloys that inhibit the growth of bacteria, viruses, and fungi more effectively than regular brass. Studies indicate antimicrobial brass surfaces reduce pathogen viability by up to 99.9% within hours, whereas regular brass shows slower or less consistent microbial reduction. This enhanced pathogen-killing performance makes antimicrobial brass a preferred choice for high-touch applications in healthcare and public spaces.

Durability and Longevity: Antimicrobial vs. Standard Brass

Antimicrobial brass contains copper alloys enriched with elements like silver or zinc, enhancing its resistance to microbial growth and prolonging its surface integrity over time. This material exhibits superior durability compared to standard brass, which can corrode or tarnish more quickly under frequent microbial exposure. The longevity of antimicrobial brass makes it ideal for high-touch surfaces in healthcare and public environments, reducing maintenance while maintaining structural strength.

Regulatory Standards and Certifications

Antimicrobial brass meets stringent regulatory standards such as EPA registration in the United States and CE marking in Europe, ensuring its efficacy and safety in reducing microbial growth. Regular brass lacks these specific certifications, making antimicrobial brass the preferred choice for healthcare and food industry applications where hygiene compliance is critical. Certifications like ISO 22196 further validate the antimicrobial performance, reinforcing the regulatory trust in antimicrobial brass over standard brass alloys.

Cost Considerations and Market Availability

Antimicrobial brass typically incurs higher costs due to the incorporation of elements like copper and silver that inhibit microbial growth, raising production expenses compared to regular brass. Market availability of antimicrobial brass remains limited, predominantly supplied by specialized manufacturers targeting healthcare and food industry sectors. Regular brass is broadly accessible and cost-effective, making it the preferred choice for general applications without stringent hygiene requirements.

Choosing the Right Brass: Application-Based Recommendations

Antimicrobial brass contains copper and zinc alloys with added elements like silver or copper to inhibit microbial growth, making it ideal for healthcare facilities, kitchens, and high-touch surfaces to reduce infection risks. Regular brass, while durable and corrosion-resistant, lacks antimicrobial properties and suits decorative or low-contact applications such as furniture fittings and musical instruments. Selecting the right brass depends on the environment's hygiene requirements and exposure frequency to ensure safety and longevity.

Antimicrobial Brass vs Regular Brass Infographic

materialdif.com

materialdif.com