Dezincification is a specific form of corrosion where zinc is selectively leached from brass, leading to weakened structural integrity and surface degradation. Corrosion resistance in brass varies depending on its zinc content and alloy composition, with higher copper concentrations generally enhancing resistance to environmental factors. Understanding the balance between dezincification susceptibility and corrosion resistance is essential for selecting brass alloys for applications exposed to aggressive or marine environments.

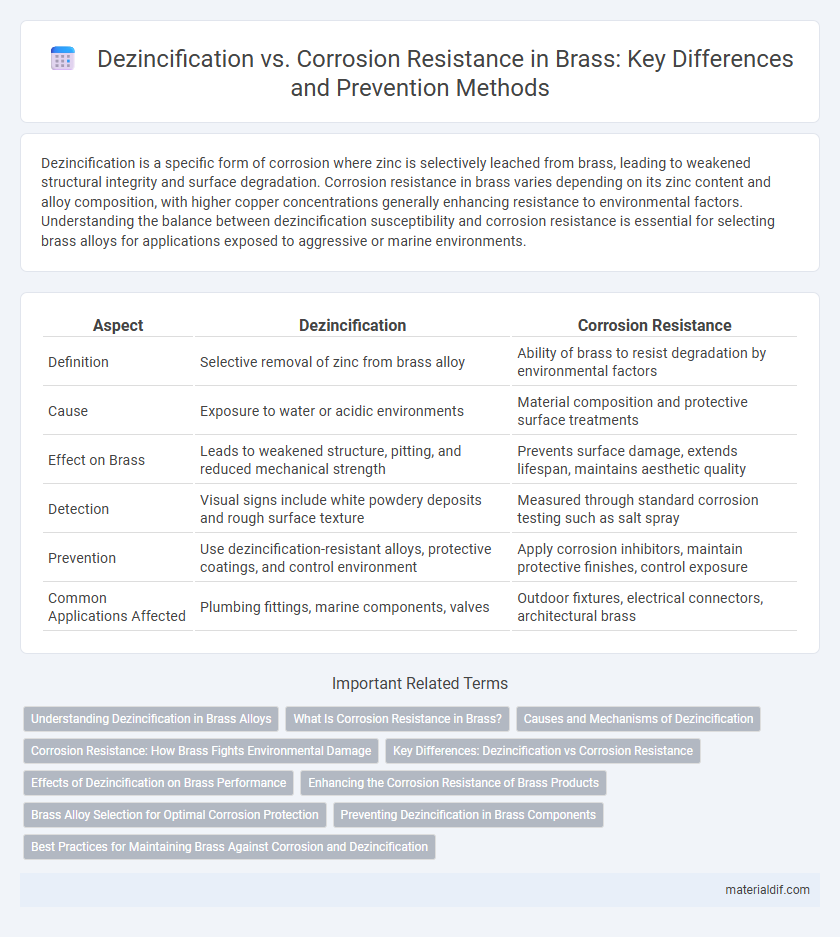

Table of Comparison

| Aspect | Dezincification | Corrosion Resistance |

|---|---|---|

| Definition | Selective removal of zinc from brass alloy | Ability of brass to resist degradation by environmental factors |

| Cause | Exposure to water or acidic environments | Material composition and protective surface treatments |

| Effect on Brass | Leads to weakened structure, pitting, and reduced mechanical strength | Prevents surface damage, extends lifespan, maintains aesthetic quality |

| Detection | Visual signs include white powdery deposits and rough surface texture | Measured through standard corrosion testing such as salt spray |

| Prevention | Use dezincification-resistant alloys, protective coatings, and control environment | Apply corrosion inhibitors, maintain protective finishes, control exposure |

| Common Applications Affected | Plumbing fittings, marine components, valves | Outdoor fixtures, electrical connectors, architectural brass |

Understanding Dezincification in Brass Alloys

Dezincification is a selective corrosion process affecting brass alloys where zinc atoms leach out, weakening the metal's structure and reducing its mechanical strength. This phenomenon primarily occurs in brass containing more than 15% zinc and is accelerated by aggressive environments such as seawater or acidic conditions. Understanding the mechanisms of dezincification is crucial for improving corrosion resistance through alloy composition control and protective treatments.

What Is Corrosion Resistance in Brass?

Corrosion resistance in brass refers to the alloy's ability to withstand chemical or electrochemical reactions that cause deterioration, especially in harsh environments. Dezincification is a specific form of corrosion in brass where zinc is selectively leached from the alloy, weakening the material's integrity. High-quality brass alloys with optimized zinc and copper content exhibit enhanced resistance to dezincification and overall corrosion, making them suitable for plumbing, marine applications, and industrial use.

Causes and Mechanisms of Dezincification

Dezincification in brass occurs primarily due to the selective leaching of zinc atoms from the alloy, driven by exposure to corrosive environments such as stagnant or aerated water containing chlorides or ammonia. The mechanism involves the electrochemical dissolution of zinc as it acts as the anodic element, leaving behind a porous and weakened copper-rich matrix prone to mechanical failure. Factors such as alloy composition, pH, dissolved oxygen levels, and temperature significantly influence the rate and severity of dezincification, contrasting with general corrosion resistance which depends on the overall stability of the entire brass microstructure.

Corrosion Resistance: How Brass Fights Environmental Damage

Brass exhibits strong corrosion resistance due to its unique alloy composition, primarily a mixture of copper and zinc, which forms a protective oxide layer that shields the metal from environmental damage. Unlike dezincification, a form of corrosion that selectively leaches zinc from the alloy, the stable copper-rich surface layer in brass enhances its durability in marine and industrial atmospheres. This natural corrosion resistance makes brass suitable for applications involving exposure to water, air pollutants, and chemical agents.

Key Differences: Dezincification vs Corrosion Resistance

Dezincification is a specific form of corrosion in brass where zinc selectively leaches out, leaving a porous copper-rich structure that weakens the alloy. Corrosion resistance in brass refers to the material's overall ability to withstand chemical or electrochemical attack without significant deterioration. The key difference lies in dezincification being a targeted degradation process affecting zinc content, while corrosion resistance encompasses the general durability of brass against various environmental factors.

Effects of Dezincification on Brass Performance

Dezincification significantly reduces brass performance by selectively leaching zinc from the alloy, leading to a weakened copper-rich porous structure that compromises mechanical strength and durability. This degradation accelerates susceptibility to stress cracking and reduces corrosion resistance, especially in environments with high chloride content or acidic conditions. As a result, dezincified brass components exhibit premature failure in plumbing, marine, and industrial applications, highlighting the critical need for alloy composition control and protective measures.

Enhancing the Corrosion Resistance of Brass Products

Enhancing the corrosion resistance of brass products involves minimizing dezincification, a common issue where zinc selectively leaches from the alloy, weakening its structure. Employing dezincification-resistant brass alloys, such as those with added arsenic or tin, significantly improves durability in marine and chemical environments. Surface treatments and protective coatings further reduce corrosion risks, extending the lifespan of brass components in demanding applications.

Brass Alloy Selection for Optimal Corrosion Protection

Brass alloy selection critically influences corrosion protection, with dezincification resistance playing a key role in durability. Alloys such as aluminum brass and silicon brass offer enhanced resistance to dezincification, reducing the risk of zinc leaching and subsequent structural weakening. Opting for these specialized brass compositions ensures optimal performance in environments prone to corrosive elements, extending the lifespan of components in plumbing, marine, and industrial applications.

Preventing Dezincification in Brass Components

Preventing dezincification in brass components requires using dezincification-resistant alloys such as C83600 or employing surface treatments like tin or nickel plating to inhibit zinc leaching. Controlling the operating environment by minimizing exposure to oxygen-rich, acidic, or chlorinated media significantly reduces the risk of dezincification. Regular maintenance combined with corrosion inhibitors tailored for brass ensures long-term durability and preservation of mechanical integrity.

Best Practices for Maintaining Brass Against Corrosion and Dezincification

Maintaining brass against dezincification and corrosion involves selecting dezincification-resistant brasses with additions such as arsenic or tin to improve alloy stability. Applying protective coatings and regularly inspecting for early signs of dezincification help prevent structural weakening and surface degradation. Employing proper water treatment to control pH, hardness, and chlorides reduces aggressive conditions that accelerate both corrosion and dezincification in brass components.

Dezincification vs Corrosion Resistance Infographic

materialdif.com

materialdif.com