Rolled brass features a uniform grain structure achieved by passing the metal through rollers, resulting in enhanced strength and smooth surface finish ideal for detailed fabrication. Spun brass is formed by rotating a brass disc at high speed while shaping it with tools, producing seamless, lightweight components with excellent structural integrity. Choosing between rolled and spun brass depends on the specific application requirements such as durability, appearance, and production technique.

Table of Comparison

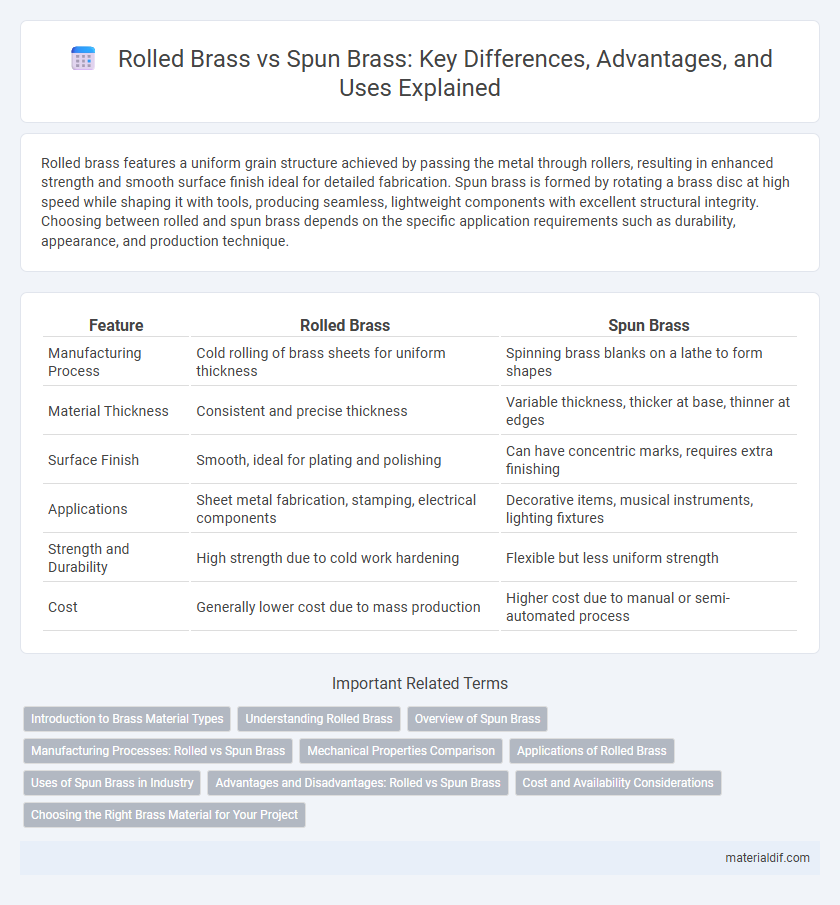

| Feature | Rolled Brass | Spun Brass |

|---|---|---|

| Manufacturing Process | Cold rolling of brass sheets for uniform thickness | Spinning brass blanks on a lathe to form shapes |

| Material Thickness | Consistent and precise thickness | Variable thickness, thicker at base, thinner at edges |

| Surface Finish | Smooth, ideal for plating and polishing | Can have concentric marks, requires extra finishing |

| Applications | Sheet metal fabrication, stamping, electrical components | Decorative items, musical instruments, lighting fixtures |

| Strength and Durability | High strength due to cold work hardening | Flexible but less uniform strength |

| Cost | Generally lower cost due to mass production | Higher cost due to manual or semi-automated process |

Introduction to Brass Material Types

Rolled brass features a flat, uniform surface produced by passing brass sheets through rollers, offering consistent thickness and smooth texture ideal for precision applications. Spun brass, created by rotating a brass disc at high speeds against a tool, results in curved, seamless shapes commonly used in decorative and functional components. Both material types provide unique mechanical properties and finishes suited for diverse industrial and artistic uses.

Understanding Rolled Brass

Rolled brass is created by passing brass alloys through heavy rollers to achieve precise thickness and smooth surface finish, resulting in uniform mechanical properties and enhanced durability. This process improves the material's machinability and strength compared to spun brass, which is formed by shaping brass sheets on a lathe, often leading to varying thickness and less consistent structural integrity. Rolled brass is ideal for applications requiring consistent dimensional tolerances and superior surface quality, such as precision instruments and architectural elements.

Overview of Spun Brass

Spun brass is a metal forming process where a flat brass disc is rotated at high speed and shaped into symmetrical, hollow designs using a tool. This technique enhances the strength and surface finish of brass components, making them ideal for decorative and industrial applications requiring precision and durability. Unlike rolled brass, spun brass offers improved grain structure and uniform thickness, contributing to superior mechanical properties.

Manufacturing Processes: Rolled vs Spun Brass

Rolled brass involves passing brass sheets through rollers to achieve consistent thickness and smooth surfaces, ideal for applications requiring uniformity and precision. Spun brass is formed by rotating a brass disc at high speeds while shaping it over a mold, allowing for complex, seamless, and curved components. These distinct manufacturing processes influence the mechanical properties and potential uses of the brass, with rolled brass favoring flat, structural applications and spun brass excelling in decorative or cylindrical forms.

Mechanical Properties Comparison

Rolled brass exhibits higher tensile strength and improved yield strength compared to spun brass due to its cold-working process, which enhances hardness and dimensional accuracy. Spun brass, produced through metal spinning, offers superior ductility and better formability, making it ideal for complex shapes and smooth finishes. Both materials provide excellent corrosion resistance, but rolled brass is generally favored for applications demanding greater mechanical durability.

Applications of Rolled Brass

Rolled brass is widely used in architectural applications, musical instruments, and decorative hardware due to its superior strength and smooth surface finish. Its excellent ductility allows for precise stamping and forming, making it ideal for intricate components in automotive and electrical industries. Additionally, rolled brass provides enhanced durability and corrosion resistance, making it suitable for plumbing fittings and marine hardware.

Uses of Spun Brass in Industry

Spun brass is widely utilized in decorative and architectural applications due to its smooth surface finish and enhanced strength from the spinning process. Industries leverage spun brass for manufacturing lamp fixtures, musical instruments, and industrial components requiring precise shapes and durability. Its resistance to corrosion and aesthetic appeal make spun brass ideal for both functional and ornamental uses in manufacturing.

Advantages and Disadvantages: Rolled vs Spun Brass

Rolled brass offers superior strength and uniform thickness, making it ideal for industrial applications requiring high durability, but it tends to be less malleable and more expensive than spun brass. Spun brass provides excellent formability and a smoother surface finish, suitable for decorative items and intricate shapes, although it may have slightly lower mechanical strength compared to rolled brass. Choosing between rolled and spun brass depends on the balance between performance requirements and design flexibility in manufacturing processes.

Cost and Availability Considerations

Rolled brass typically offers greater cost efficiency due to its standardized manufacturing process, making it widely available for bulk orders. Spun brass, while often more expensive, provides enhanced aesthetic appeal and is usually produced in smaller quantities, leading to limited availability. Industrial buyers prioritize rolled brass for large-scale projects due to its affordability, whereas spun brass suits specialized applications requiring unique finishes despite higher costs.

Choosing the Right Brass Material for Your Project

Rolled brass offers superior strength and uniform thickness, making it ideal for structural applications and precision components, while spun brass provides excellent formability and surface finish, suitable for decorative and intricate designs. Consider the specific project requirements such as durability, shape complexity, and aesthetic appeal when selecting between rolled and spun brass. Choosing the correct brass material ensures optimal performance and longevity tailored to your project's functional and visual demands.

Rolled Brass vs Spun Brass Infographic

materialdif.com

materialdif.com