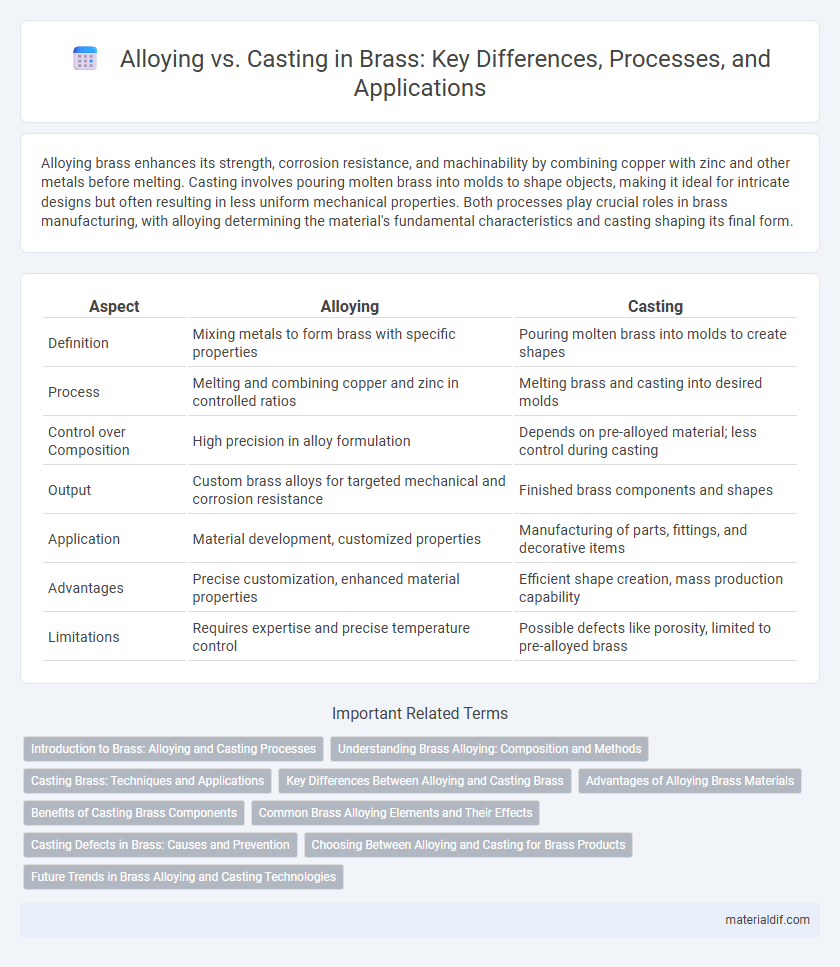

Alloying brass enhances its strength, corrosion resistance, and machinability by combining copper with zinc and other metals before melting. Casting involves pouring molten brass into molds to shape objects, making it ideal for intricate designs but often resulting in less uniform mechanical properties. Both processes play crucial roles in brass manufacturing, with alloying determining the material's fundamental characteristics and casting shaping its final form.

Table of Comparison

| Aspect | Alloying | Casting |

|---|---|---|

| Definition | Mixing metals to form brass with specific properties | Pouring molten brass into molds to create shapes |

| Process | Melting and combining copper and zinc in controlled ratios | Melting brass and casting into desired molds |

| Control over Composition | High precision in alloy formulation | Depends on pre-alloyed material; less control during casting |

| Output | Custom brass alloys for targeted mechanical and corrosion resistance | Finished brass components and shapes |

| Application | Material development, customized properties | Manufacturing of parts, fittings, and decorative items |

| Advantages | Precise customization, enhanced material properties | Efficient shape creation, mass production capability |

| Limitations | Requires expertise and precise temperature control | Possible defects like porosity, limited to pre-alloyed brass |

Introduction to Brass: Alloying and Casting Processes

Brass is an alloy primarily composed of copper and zinc, where alloying allows precise control over its mechanical properties and corrosion resistance. The casting process involves melting the brass alloy and pouring it into molds to create complex shapes with fine details, critical for manufacturing components like fittings and decorative items. Understanding the interplay between alloying composition and casting techniques is essential for optimizing brass performance in industrial and artistic applications.

Understanding Brass Alloying: Composition and Methods

Brass alloying involves combining copper with varying amounts of zinc, typically between 5% and 45%, to achieve desired mechanical properties and corrosion resistance. Common alloying methods include melting and mixing metals in controlled environments, which ensure uniform composition and enhance machinability, strength, and ductility. Casting brass alloys often requires precise temperature control to prevent defects and optimize grain structure for improved performance in plumbing, musical instruments, and decorative applications.

Casting Brass: Techniques and Applications

Casting brass involves pouring molten brass into molds to create complex shapes and intricate designs with high precision. Common techniques include sand casting, investment casting, and die casting, each offering varying levels of surface finish and dimensional accuracy tailored to specific industrial needs. This process is widely used in manufacturing components such as fittings, valves, musical instruments, and decorative hardware due to brass's excellent corrosion resistance and machinability.

Key Differences Between Alloying and Casting Brass

Alloying brass involves combining copper with zinc and sometimes other metals to create a material with specific mechanical properties, corrosion resistance, and color variations. Casting brass refers to the process of melting the alloy and pouring it into molds to achieve precise shapes and intricate designs. The key differences lie in alloying affecting the brass composition and properties, while casting determines the final product form and surface finish.

Advantages of Alloying Brass Materials

Alloying brass materials enhances mechanical properties such as strength, corrosion resistance, and machinability, making them suitable for diverse industrial applications. The precise control over the composition in alloying allows customization of brass for specific performance requirements, including improved thermal and electrical conductivity. This method results in consistent, high-quality materials that outperform cast brass in structural integrity and durability.

Benefits of Casting Brass Components

Casting brass components allows for the creation of complex shapes and intricate designs that are difficult to achieve through alloying alone. The process enhances material uniformity and mechanical properties, resulting in improved strength and corrosion resistance. Casting also reduces machining costs and material waste, making it a cost-effective method for producing high-quality brass parts.

Common Brass Alloying Elements and Their Effects

Common brass alloying elements include zinc, tin, and lead, each significantly influencing the metal's properties. Zinc primarily enhances strength and corrosion resistance, while tin improves wear resistance and reduces dezincification. Adding lead increases machinability without notably affecting mechanical strength, making these elements crucial for tailoring brass to specific industrial applications.

Casting Defects in Brass: Causes and Prevention

Casting defects in brass often arise from improper temperature control, contamination, and gas entrapment during the casting process. Common defects include porosity, cold shuts, and inclusions, which compromise the mechanical properties and surface finish of brass components. Implementing precise temperature management, maintaining clean metal handling practices, and using appropriate degassing techniques effectively prevent casting defects in brass alloys.

Choosing Between Alloying and Casting for Brass Products

Selecting between alloying and casting for brass products hinges on the desired mechanical properties and manufacturing precision. Alloying allows for tailored compositions enhancing strength, corrosion resistance, and machinability, ideal for custom applications requiring specific performance characteristics. Casting offers cost-effective mass production with complex shapes but may sacrifice uniformity and exact composition control found in alloyed brass formulations.

Future Trends in Brass Alloying and Casting Technologies

Future trends in brass alloying emphasize the development of eco-friendly, lead-free compositions to meet stringent environmental regulations and enhance recyclability. Advances in casting technologies focus on precision methods such as investment casting and additive manufacturing to improve dimensional accuracy and reduce material waste. Integration of AI and real-time process monitoring is driving smarter control over microstructure optimization and mechanical properties in brass components.

Alloying vs Casting Infographic

materialdif.com

materialdif.com