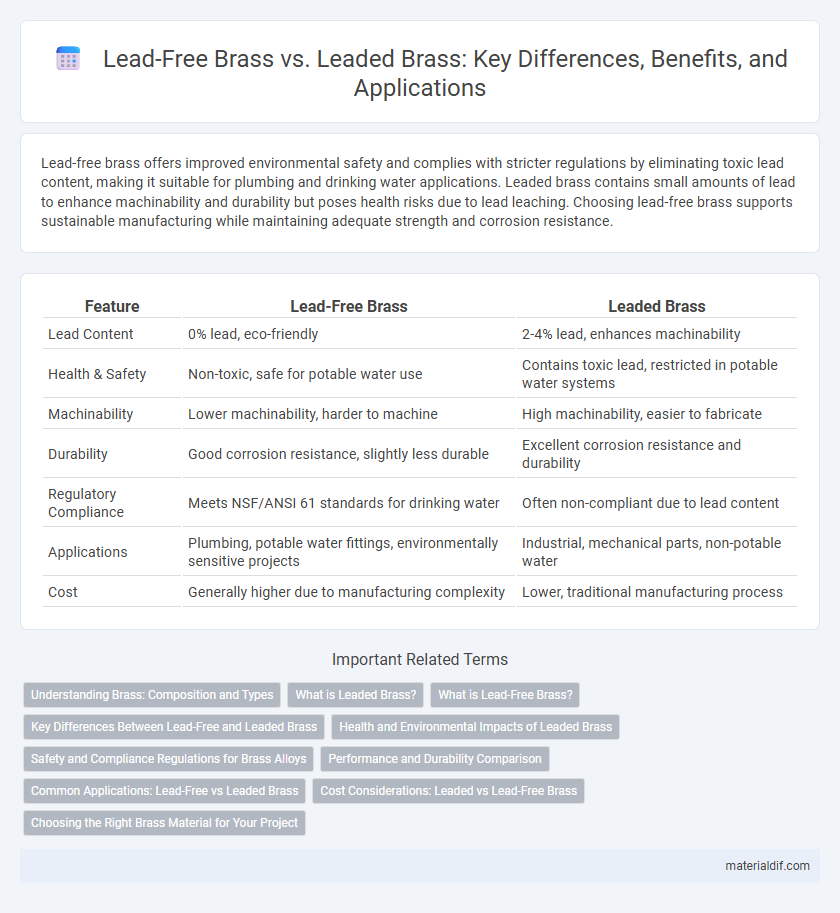

Lead-free brass offers improved environmental safety and complies with stricter regulations by eliminating toxic lead content, making it suitable for plumbing and drinking water applications. Leaded brass contains small amounts of lead to enhance machinability and durability but poses health risks due to lead leaching. Choosing lead-free brass supports sustainable manufacturing while maintaining adequate strength and corrosion resistance.

Table of Comparison

| Feature | Lead-Free Brass | Leaded Brass |

|---|---|---|

| Lead Content | 0% lead, eco-friendly | 2-4% lead, enhances machinability |

| Health & Safety | Non-toxic, safe for potable water use | Contains toxic lead, restricted in potable water systems |

| Machinability | Lower machinability, harder to machine | High machinability, easier to fabricate |

| Durability | Good corrosion resistance, slightly less durable | Excellent corrosion resistance and durability |

| Regulatory Compliance | Meets NSF/ANSI 61 standards for drinking water | Often non-compliant due to lead content |

| Applications | Plumbing, potable water fittings, environmentally sensitive projects | Industrial, mechanical parts, non-potable water |

| Cost | Generally higher due to manufacturing complexity | Lower, traditional manufacturing process |

Understanding Brass: Composition and Types

Lead-free brass is primarily composed of copper, zinc, and small amounts of other elements such as tin or iron, offering improved environmental safety and compliance with regulations like RoHS. Leaded brass contains a small percentage of lead, typically 1-3%, which enhances machinability and wear resistance but raises health concerns due to lead toxicity. Understanding these differences in composition helps manufacturers select the appropriate brass type for applications requiring either safer handling or superior mechanical properties.

What is Leaded Brass?

Leaded brass is an alloy composed primarily of copper and zinc, with added lead to improve machinability and ease of fabrication. Typically containing 1% to 3% lead, this material offers enhanced cutting performance and reduces tool wear during manufacturing processes. Despite its machining advantages, leaded brass poses health and environmental concerns due to lead's toxicity, prompting increased use of lead-free alternatives in many industries.

What is Lead-Free Brass?

Lead-Free Brass is an alloy composed primarily of copper and zinc, with little to no lead content, designed to meet stringent health and environmental standards. It offers enhanced safety for plumbing and potable water applications by reducing lead exposure risks while maintaining excellent machinability and corrosion resistance. This eco-friendly material complies with regulations such as the Safe Drinking Water Act and NSF/ANSI 61 standards, ensuring safe use in residential and commercial systems.

Key Differences Between Lead-Free and Leaded Brass

Lead-free brass contains minimal or no lead content, enhancing its environmental safety and compliance with health regulations, unlike traditional leaded brass which typically contains 2-3% lead to improve machinability. The absence of lead in lead-free brass reduces potential toxicity risks in potable water systems, making it the preferred choice for plumbing fixtures. Leaded brass offers superior machinability and cost-effectiveness but faces increasing restrictions due to health concerns and regulatory standards.

Health and Environmental Impacts of Leaded Brass

Leaded brass contains a significant percentage of lead, which poses severe health risks through lead exposure during manufacturing and use, including neurological damage and toxic contamination. Environmental impacts include soil and water pollution from lead leaching, contributing to ecosystem toxicity and bioaccumulation. Lead-free brass offers a safer alternative by eliminating these hazards, promoting healthier workplace conditions and reduced environmental footprint.

Safety and Compliance Regulations for Brass Alloys

Lead-free brass alloys are essential for meeting stringent safety and compliance regulations, especially in potable water applications, where lead content must not exceed 0.25%. Leaded brass, containing typically 2-3% lead, improves machinability but does not comply with U.S. Safe Drinking Water Act (SDWA) requirements and similar international standards. Regulatory bodies increasingly mandate lead-free brass to reduce lead exposure risks, ensuring safer consumer products and environmental sustainability in brass alloy usage.

Performance and Durability Comparison

Lead-free brass exhibits improved corrosion resistance and complies with stringent environmental regulations, making it ideal for potable water applications. Leaded brass offers superior machinability and excellent durability due to its lower melting point and higher lead content, enhancing tool life during manufacturing. Performance-wise, lead-free brass may have slightly reduced machinability but excels in long-term durability and safety, while leaded brass provides enhanced workability with increased wear resistance.

Common Applications: Lead-Free vs Leaded Brass

Lead-free brass is widely used in plumbing, potable water systems, and food contact applications due to its compliance with strict environmental regulations and health standards. Leaded brass remains common in industrial settings, electrical components, and automotive parts where machinability and cost-effectiveness are prioritized. Both lead-free and leaded brass offer excellent corrosion resistance and durability, but the choice depends on regulatory requirements and the specific application's safety criteria.

Cost Considerations: Leaded vs Lead-Free Brass

Lead-free brass typically incurs higher material and production costs due to stringent environmental regulations and the need for alternative alloying elements, increasing manufacturing complexity. Leaded brass, while cheaper to produce owing to its established composition and ease of machining, faces rising regulatory restrictions impacting its market availability and long-term cost-effectiveness. Evaluating cost considerations requires balancing upfront expenses against compliance, health safety standards, and potential liability in applications such as plumbing and electrical components.

Choosing the Right Brass Material for Your Project

Selecting the right brass material depends on project requirements for safety, durability, and machinability. Lead-free brass is ideal for plumbing and food-related applications due to its non-toxic composition and environmental compliance, while leaded brass offers superior machinability and wear resistance for industrial components. Evaluating factors such as lead content limits, corrosion resistance, and mechanical strength ensures optimal performance and regulatory adherence.

Lead-Free Brass vs Leaded Brass Infographic

materialdif.com

materialdif.com