The CZ108 and CZ121 brass pet models differ primarily in size and durability, with the CZ108 offering a more compact design ideal for smaller pets. The CZ121 provides enhanced strength and weather resistance, making it suitable for outdoor use and larger animals. Choosing between the two depends on your pet's size and the environment where the brass pet accessory will be used.

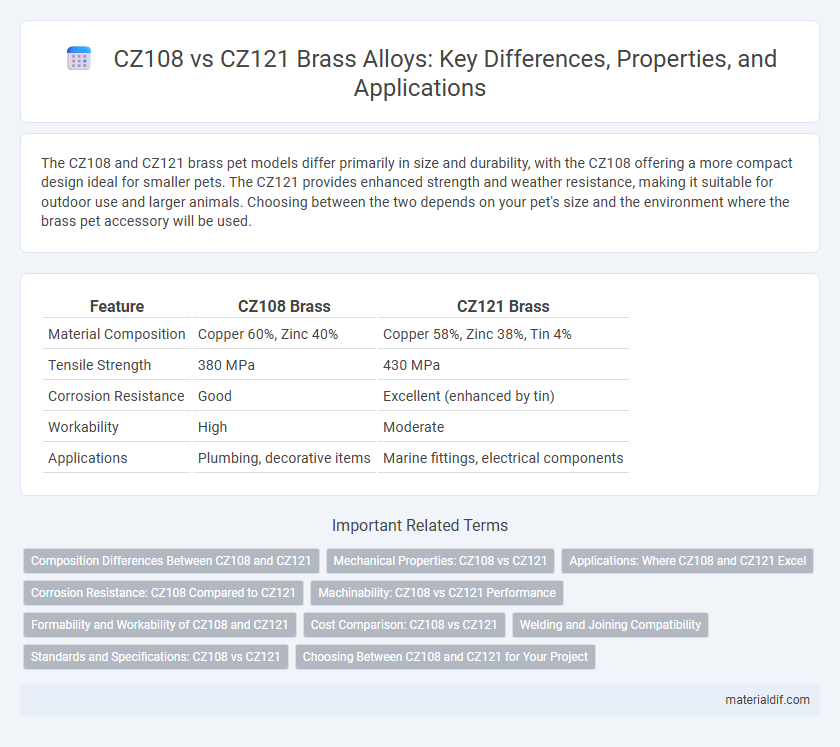

Table of Comparison

| Feature | CZ108 Brass | CZ121 Brass |

|---|---|---|

| Material Composition | Copper 60%, Zinc 40% | Copper 58%, Zinc 38%, Tin 4% |

| Tensile Strength | 380 MPa | 430 MPa |

| Corrosion Resistance | Good | Excellent (enhanced by tin) |

| Workability | High | Moderate |

| Applications | Plumbing, decorative items | Marine fittings, electrical components |

Composition Differences Between CZ108 and CZ121

CZ108 brass is primarily composed of about 70% copper and 30% zinc, offering a classic alpha brass structure ideal for general-purpose applications. CZ121 brass, on the other hand, contains approximately 60% copper and 40% zinc, which provides higher strength and enhanced corrosion resistance due to its beta brass characteristics. These composition differences significantly influence the machinability, mechanical properties, and suitability for various industrial uses of each brass alloy.

Mechanical Properties: CZ108 vs CZ121

CZ108 brass alloy exhibits higher tensile strength and improved hardness compared to CZ121, making it more suitable for applications requiring enhanced mechanical durability. CZ121 offers better corrosion resistance and slightly greater elongation, providing increased flexibility under mechanical stress. Both alloys demonstrate good machinability, but CZ108's superior mechanical properties make it preferable for heavy-duty components.

Applications: Where CZ108 and CZ121 Excel

CZ108 brass excels in marine and automotive applications due to its superior corrosion resistance and high tensile strength, making it ideal for harsh environments. CZ121 brass offers exceptional machinability and is commonly used in precision engineering and electrical components where dimensional accuracy is critical. Both alloys are prized in manufacturing, with CZ108 favored for durability and CZ121 preferred for intricate fabrication.

Corrosion Resistance: CZ108 Compared to CZ121

CZ108 brass exhibits superior corrosion resistance compared to CZ121 due to its higher copper content and balanced alloy composition, which enhances its durability in harsh environments. The increased zinc percentage in CZ121 makes it more susceptible to dezincification and surface degradation when exposed to moisture or acidic conditions. Consequently, CZ108 is the preferred choice for applications requiring improved longevity and corrosion resistance, such as plumbing fittings and marine hardware.

Machinability: CZ108 vs CZ121 Performance

CZ108 brass offers superior machinability compared to CZ121 due to its lower hardness and better chip formation, resulting in faster cutting speeds and reduced tool wear. CZ121, while providing higher strength and corrosion resistance, tends to produce a tougher machining environment with increased tool stress and potential for built-up edge. Manufacturers often prefer CZ108 for high-precision, high-speed machining applications where enhanced productivity and surface finish are critical.

Formability and Workability of CZ108 and CZ121

CZ108 brass offers superior formability due to its higher copper content and lower zinc percentage, making it ideal for intricate stamping and bending applications. CZ121, with slightly increased zinc content, provides enhanced strength and hardness but sacrifices some workability compared to CZ108. The choice between CZ108 and CZ121 depends on whether flexibility in forming or mechanical resilience is prioritized in the manufacturing process.

Cost Comparison: CZ108 vs CZ121

The CZ108 brass cartridge case is typically more cost-effective than the CZ121 due to its simpler manufacturing process and widespread availability. CZ121, featuring enhanced durability and corrosion resistance, commands a higher price reflecting its premium materials and production techniques. Buyers prioritizing budget constraints often lean towards CZ108, while those valuing longevity and performance may invest in the CZ121 despite its increased cost.

Welding and Joining Compatibility

CZ108 brass exhibits superior welding and joining compatibility due to its higher copper content and lower lead levels, ensuring better thermal conductivity and reduced risk of cracking during the welding process. In contrast, CZ121 brass, with increased zinc content, may present challenges such as porosity and brittleness when subjected to aggressive welding techniques. Selecting CZ108 for applications requiring robust joints and structural integrity enhances the overall reliability of brass assemblies in industrial settings.

Standards and Specifications: CZ108 vs CZ121

CZ108 brass conforms primarily to ASTM B16 standards, offering excellent machinability and corrosion resistance for general engineering applications. In contrast, CZ121 brass adheres to JIS H3250 specifications, providing superior strength and higher copper content for specialized manufacturing requiring enhanced durability. Both alloys meet distinct international standards that dictate their elemental composition and mechanical properties, making CZ108 ideal for precision parts, while CZ121 suits heavy-duty components.

Choosing Between CZ108 and CZ121 for Your Project

Choosing between CZ108 and CZ121 brass types depends on your project's requirements for strength and machinability. CZ108 offers excellent machinability with moderate strength, ideal for intricate components and machining precision. CZ121 provides higher strength and better corrosion resistance, making it suitable for structural applications and environments exposed to moisture.

CZ108 vs CZ121 Infographic

materialdif.com

materialdif.com