Forged brass offers superior strength and durability due to its solid, heat-treated construction, making it ideal for high-stress applications. Stamped brass, created by pressing thin sheets into shape, provides cost-effective and lightweight solutions but may lack the robustness of forged pieces. Choosing between forged and stamped brass depends on the balance needed between strength, precision, and budget for specific projects.

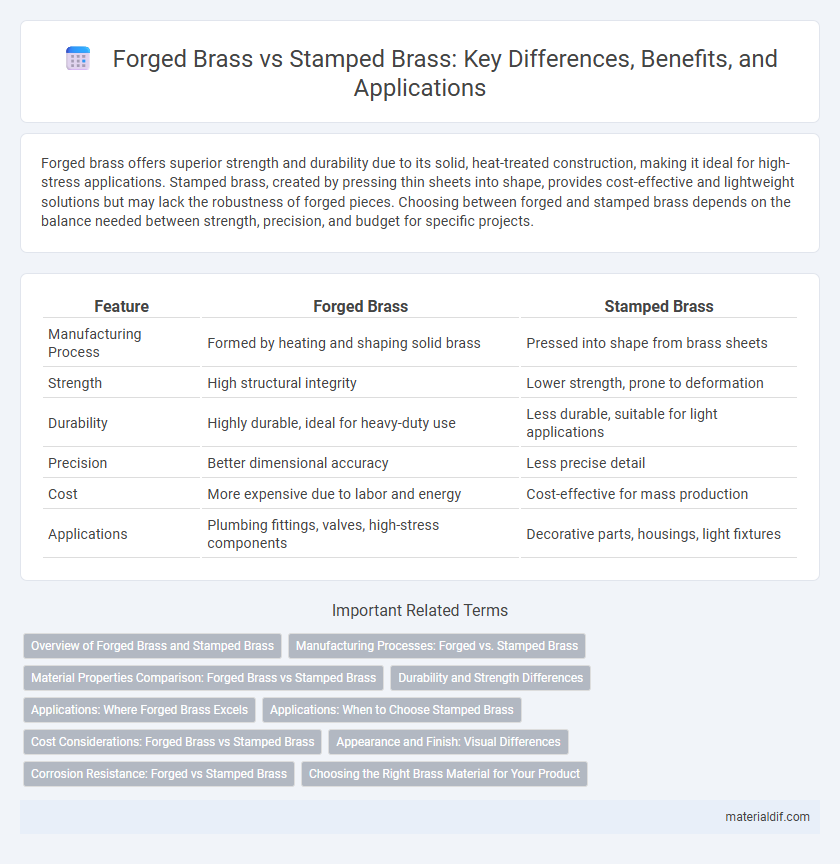

Table of Comparison

| Feature | Forged Brass | Stamped Brass |

|---|---|---|

| Manufacturing Process | Formed by heating and shaping solid brass | Pressed into shape from brass sheets |

| Strength | High structural integrity | Lower strength, prone to deformation |

| Durability | Highly durable, ideal for heavy-duty use | Less durable, suitable for light applications |

| Precision | Better dimensional accuracy | Less precise detail |

| Cost | More expensive due to labor and energy | Cost-effective for mass production |

| Applications | Plumbing fittings, valves, high-stress components | Decorative parts, housings, light fixtures |

Overview of Forged Brass and Stamped Brass

Forged brass is produced by heating and shaping solid brass billets under high pressure, resulting in a dense, durable material with superior mechanical properties, ideal for heavy-duty applications. Stamped brass is created by cutting and shaping thin brass sheets using dies and presses, offering cost-effective production with consistent thickness but less structural strength compared to forged brass. The choice between forged and stamped brass depends on performance requirements, with forged brass preferred for high-stress environments and stamped brass for lightweight, decorative uses.

Manufacturing Processes: Forged vs. Stamped Brass

Forged brass undergoes high-pressure shaping through heating and hammering, resulting in a denser and stronger metal structure with enhanced durability. Stamped brass is produced by pressing flat brass sheets into desired shapes using dies, enabling faster and cost-effective mass production but with thinner and less robust parts. The forging process yields superior mechanical properties ideal for heavy-duty applications, while stamping suits intricate designs where high volume and precision are prioritized.

Material Properties Comparison: Forged Brass vs Stamped Brass

Forged brass exhibits superior strength and durability due to its denser grain structure formed during the forging process, enhancing resistance to impact and wear. Stamped brass, created by pressing sheet metal, tends to have lower mechanical strength and may be more prone to deformation under stress. The material hardness and tensile strength of forged brass typically surpass those of stamped brass, making it preferable for high-stress applications requiring long-term reliability.

Durability and Strength Differences

Forged brass exhibits superior durability and strength compared to stamped brass due to its manufacturing process, which involves shaping the metal under high pressure, resulting in a denser and more resilient structure. Stamped brass is produced by cutting and pressing thin sheets, making it more prone to bending and fatigue over time. This difference in fabrication leads forged brass to be preferred for applications requiring long-lasting performance and mechanical robustness.

Applications: Where Forged Brass Excels

Forged brass offers superior strength and durability, making it ideal for high-stress applications such as plumbing valves, heavy-duty fittings, and intricate hardware components. Its enhanced grain structure provides excellent resistance to wear, corrosion, and fatigue, ensuring long-lasting performance in demanding environments. Unlike stamped brass, forged brass is preferred in precision engineering and automotive parts requiring reliable mechanical integrity and structural resilience.

Applications: When to Choose Stamped Brass

Stamped brass is ideal for high-volume applications requiring lightweight components with consistent dimensions, such as electrical connectors, decorative hardware, and musical instruments. Its cost-effectiveness and ability to produce intricate shapes rapidly make it suitable for consumer electronics and automotive trim. Choose stamped brass when precision and production speed are critical without compromising moderate strength and durability.

Cost Considerations: Forged Brass vs Stamped Brass

Forged brass typically incurs higher production costs due to the intensive labor, energy, and material waste involved in shaping solid metal billets under high pressure. Stamped brass offers a more cost-effective alternative, as it involves pressing sheet metal into desired forms using dies, resulting in faster production and less material usage. Manufacturers often select stamped brass for large volumes requiring economical manufacturing, while forged brass is preferred for applications demanding superior strength and durability despite the increased cost.

Appearance and Finish: Visual Differences

Forged brass typically exhibits a smoother, more uniform surface with a richer, polished finish due to the metal's compression during forging. Stamped brass often displays slight irregularities and a less refined texture, as it is shaped by pressing sheets into molds. The visual differences influence aesthetic appeal, with forged brass favored for high-end applications requiring a premium, consistent look.

Corrosion Resistance: Forged vs Stamped Brass

Forged brass exhibits superior corrosion resistance due to its denser grain structure and fewer internal voids compared to stamped brass, which often contains microscopic imperfections from the stamping process. The forging method enhances the alloy's homogeneity, reducing susceptibility to oxidation and environmental degradation. In marine and industrial applications, forged brass outperforms stamped brass by maintaining structural integrity and surface appearance longer under corrosive conditions.

Choosing the Right Brass Material for Your Product

Forged brass offers superior strength and durability due to its density and uniform grain structure, making it ideal for high-stress applications such as hardware and plumbing components. Stamped brass provides cost-effective production with consistent thickness and precision, suitable for decorative and lightweight products. Selecting the right brass material depends on balancing performance requirements and manufacturing costs to meet specific product demands.

Forged Brass vs Stamped Brass Infographic

materialdif.com

materialdif.com