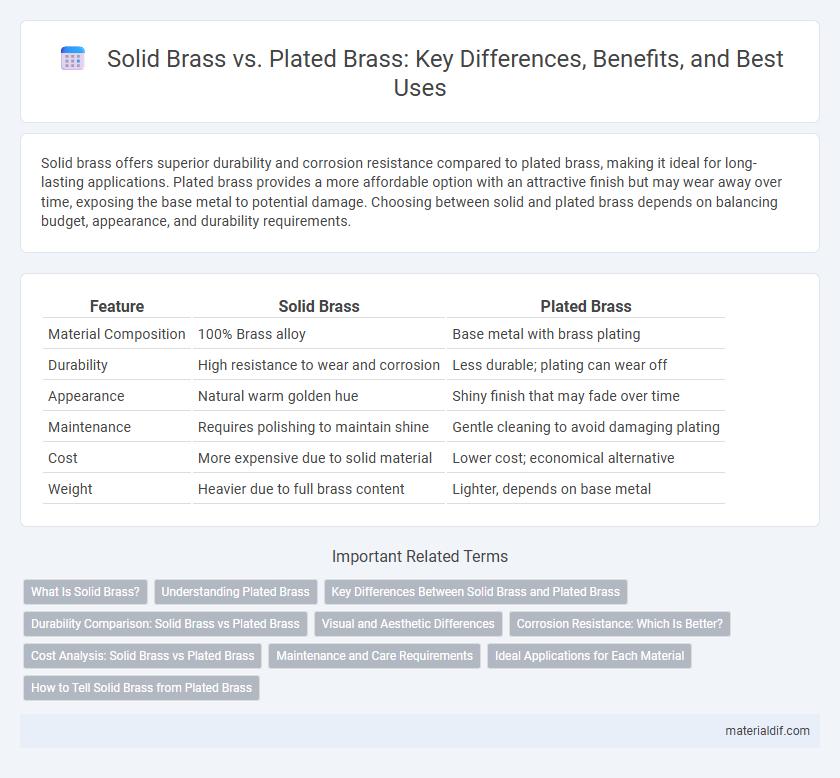

Solid brass offers superior durability and corrosion resistance compared to plated brass, making it ideal for long-lasting applications. Plated brass provides a more affordable option with an attractive finish but may wear away over time, exposing the base metal to potential damage. Choosing between solid and plated brass depends on balancing budget, appearance, and durability requirements.

Table of Comparison

| Feature | Solid Brass | Plated Brass |

|---|---|---|

| Material Composition | 100% Brass alloy | Base metal with brass plating |

| Durability | High resistance to wear and corrosion | Less durable; plating can wear off |

| Appearance | Natural warm golden hue | Shiny finish that may fade over time |

| Maintenance | Requires polishing to maintain shine | Gentle cleaning to avoid damaging plating |

| Cost | More expensive due to solid material | Lower cost; economical alternative |

| Weight | Heavier due to full brass content | Lighter, depends on base metal |

What Is Solid Brass?

Solid brass is an alloy composed primarily of copper and zinc, known for its durability, corrosion resistance, and natural antimicrobial properties. Unlike plated brass, which features a thin layer of brass coating over a base metal, solid brass is composed entirely of brass throughout its structure, ensuring consistent strength and longevity. This material is widely used in hardware, musical instruments, and decorative items due to its malleability and ability to develop a unique patina over time.

Understanding Plated Brass

Plated brass consists of a base layer of less expensive metal, such as copper or zinc, coated with a thin layer of brass to enhance its appearance and corrosion resistance. This method offers a more cost-effective alternative to solid brass while maintaining similar visual appeal and durability for decorative applications. Understanding plated brass helps consumers balance budget considerations with desired aesthetics and longevity in products like fixtures and hardware.

Key Differences Between Solid Brass and Plated Brass

Solid brass consists entirely of an alloy made primarily of copper and zinc, giving it superior durability, corrosion resistance, and a naturally warm, golden appearance. Plated brass features a thin layer of brass coating over a different metal, often resulting in lower durability and increased susceptibility to wear, tarnish, and corrosion over time. The manufacturing process and material composition directly impact the longevity, maintenance, and aesthetic quality of solid brass versus plated brass products.

Durability Comparison: Solid Brass vs Plated Brass

Solid brass offers superior durability due to its composition of pure copper and zinc, making it resistant to corrosion, wear, and tarnish over time. Plated brass, while initially attractive and cost-effective, relies on a thin layer of metal coating that can wear off, exposing the base brass to oxidation and degradation. For long-term applications requiring strength and resistance to environmental damage, solid brass significantly outperforms plated brass in maintaining structural integrity and appearance.

Visual and Aesthetic Differences

Solid brass exhibits a rich, warm golden hue that deepens with age, offering a natural patina and enduring luster. Plated brass, coated with a thin layer of metals like chrome or nickel, often presents a shinier, more uniform finish but lacks the depth and character of solid brass. Over time, plated brass can wear away, revealing the base metal beneath and reducing its visual appeal compared to the lasting elegance of solid brass.

Corrosion Resistance: Which Is Better?

Solid brass offers superior corrosion resistance compared to plated brass due to its uniform metal composition, which prevents the exposure of underlying materials. Plated brass can suffer from corrosion once the protective plating wears off or gets scratched, exposing the base metal to moisture and oxidization. Therefore, for applications where long-term durability in corrosive environments is critical, solid brass is the better choice.

Cost Analysis: Solid Brass vs Plated Brass

Solid brass typically incurs higher upfront costs due to its 100% copper and zinc composition, offering superior durability and corrosion resistance. Plated brass features a core of base metal coated with a thin layer of brass, reducing manufacturing expenses but potentially increasing long-term maintenance costs from wear and oxidation. Evaluating total cost of ownership requires balancing initial investment with lifespan and appearance retention, where solid brass generally provides greater value for heavy-use applications.

Maintenance and Care Requirements

Solid brass requires less frequent maintenance as it develops a natural patina over time that protects the metal from corrosion, while plated brass demands more careful upkeep to prevent the thin layer from wearing away. Regular cleaning of solid brass involves gentle polishing with appropriate brass cleaners to maintain its shine, whereas plated brass should be cleaned with mild, non-abrasive products to avoid damaging the plating. Proper care extends the lifespan of both materials, but solid brass generally offers greater durability and easier long-term maintenance.

Ideal Applications for Each Material

Solid brass is ideal for applications requiring durability and corrosion resistance, such as plumbing fixtures, musical instruments, and high-quality hardware, due to its dense composition and long-lasting properties. Plated brass, featuring a base of less expensive metals coated with a thin layer of brass, suits decorative purposes like furniture accents, light switch covers, and costume jewelry, offering aesthetic appeal at a lower cost. Choosing between solid and plated brass depends on the balance between budget, wear resistance, and visual appearance required for the specific use case.

How to Tell Solid Brass from Plated Brass

Solid brass can be identified by its heavier weight and uniform composition throughout, whereas plated brass features a thin layer of brass bonded to a base metal, which is often lighter and prone to wear exposing the underlying material. Testing by scratching a small, inconspicuous area reveals solid brass's consistent color beneath the surface, while plated brass quickly shows a different metal underneath. Magnetic tests can also help, as solid brass is non-magnetic, whereas plated items with ferrous cores may attract magnets.

Solid Brass vs Plated Brass Infographic

materialdif.com

materialdif.com