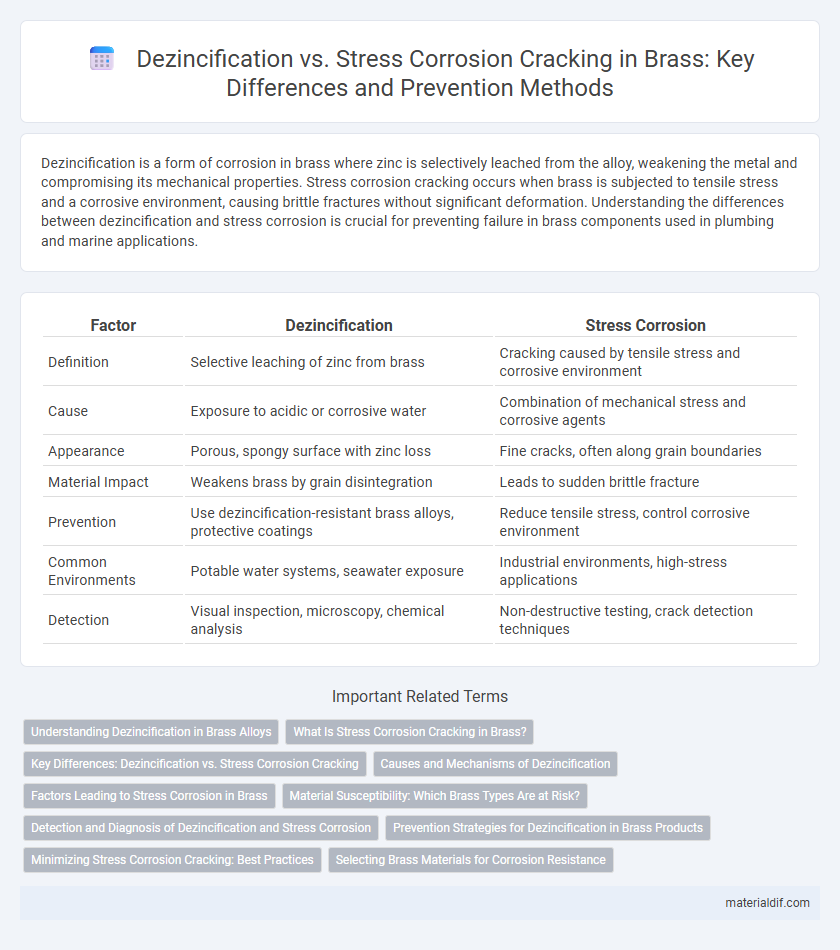

Dezincification is a form of corrosion in brass where zinc is selectively leached from the alloy, weakening the metal and compromising its mechanical properties. Stress corrosion cracking occurs when brass is subjected to tensile stress and a corrosive environment, causing brittle fractures without significant deformation. Understanding the differences between dezincification and stress corrosion is crucial for preventing failure in brass components used in plumbing and marine applications.

Table of Comparison

| Factor | Dezincification | Stress Corrosion |

|---|---|---|

| Definition | Selective leaching of zinc from brass | Cracking caused by tensile stress and corrosive environment |

| Cause | Exposure to acidic or corrosive water | Combination of mechanical stress and corrosive agents |

| Appearance | Porous, spongy surface with zinc loss | Fine cracks, often along grain boundaries |

| Material Impact | Weakens brass by grain disintegration | Leads to sudden brittle fracture |

| Prevention | Use dezincification-resistant brass alloys, protective coatings | Reduce tensile stress, control corrosive environment |

| Common Environments | Potable water systems, seawater exposure | Industrial environments, high-stress applications |

| Detection | Visual inspection, microscopy, chemical analysis | Non-destructive testing, crack detection techniques |

Understanding Dezincification in Brass Alloys

Dezincification in brass alloys occurs when zinc selectively corrodes from the alloy, leaving behind a porous and weakened copper-rich structure that compromises mechanical integrity. This phenomenon typically arises in environments containing oxygenated water and chloride ions, accelerating zinc leaching and reducing brass's durability. Understanding the microstructural changes during dezincification helps in distinguishing it from stress corrosion cracking, which involves tensile stress and brittle fracture in brass components.

What Is Stress Corrosion Cracking in Brass?

Stress corrosion cracking in brass occurs when tensile stress and a corrosive environment, such as ammonia or chlorides, interact to cause cracks that propagate through the metal. This form of cracking is particularly problematic in dezincification-resistant brass alloys, where selective leaching of zinc weakens the material's microstructure under stress. Understanding the mechanisms of stress corrosion cracking helps improve brass formulations and preventive measures, ensuring longer service life in plumbing and marine applications.

Key Differences: Dezincification vs. Stress Corrosion Cracking

Dezincification primarily involves the selective leaching of zinc from brass, leading to a porous and weakened copper-rich surface, whereas stress corrosion cracking (SCC) occurs due to the combined effect of tensile stress and a corrosive environment causing brittle fractures. Dezincification is often caused by exposure to acidic or oxygenated water, while SCC typically arises from chloride-containing solutions under tensile stress. The main difference lies in dezincification's material degradation through zinc loss versus SCC's crack propagation driven by mechanical stress and chemical attack.

Causes and Mechanisms of Dezincification

Dezincification is a selective corrosion process where zinc is leached from brass alloys, primarily caused by exposure to aggressive aqueous environments containing chlorides or ammonia, leading to the formation of a porous copper-rich layer. The electrochemical mechanism involves anodic dissolution of zinc at micro-galvanic sites, driven by differences in electrode potentials between zinc and copper phases within the brass matrix. Stress corrosion cracking in brass, in contrast, results from tensile stresses combined with corrosive agents, affecting the alloy's microstructure differently and not primarily characterized by zinc depletion.

Factors Leading to Stress Corrosion in Brass

Stress corrosion in brass primarily results from the combined effects of tensile stress and a corrosive environment containing ammonia or chlorides. Microstructural factors such as grain boundary composition and residual stress from manufacturing processes exacerbate susceptibility to cracking. High temperatures and alloy composition, particularly elevated zinc and lead content, further increase the likelihood of stress corrosion cracking in brass components.

Material Susceptibility: Which Brass Types Are at Risk?

Dezincification primarily affects alpha-beta brass alloys with higher zinc content, leading to selective leaching of zinc and weakening the material structure. Stress corrosion cracking (SCC) predominantly targets single-phase alpha brasses but can also occur in dezincification-susceptible alloys under tensile stress and corrosive environments. High-leaded and low-zinc brasses exhibit better resistance to both dezincification and SCC, making them preferable for applications exposed to aggressive aqueous conditions.

Detection and Diagnosis of Dezincification and Stress Corrosion

Detection and diagnosis of dezincification in brass primarily involve visual inspection for a rough, porous surface and non-destructive testing methods such as ultrasonic testing to detect subsurface material loss. Stress corrosion cracking (SCC) is identified through techniques like dye penetrant testing, acoustic emission monitoring, and metallographic examination to reveal crack initiation and propagation along grain boundaries. Proper diagnosis distinguishes dezincification's selective zinc removal from SCC's tensile stress-induced fractures, enabling targeted remediation strategies.

Prevention Strategies for Dezincification in Brass Products

Prevention strategies for dezincification in brass products include selecting dezincification-resistant alloys such as duplex brass or aluminum brass, which significantly reduce zinc leaching. Applying protective coatings like epoxy or polymer linings effectively limits corrosive exposure and inhibits the dezincification process. Implementing proper water treatment methods to control pH, chloride, and dissolved oxygen levels further minimizes the risk of dezincification in brass components.

Minimizing Stress Corrosion Cracking: Best Practices

Minimizing stress corrosion cracking (SCC) in brass requires controlling environmental factors such as reducing chlorides and maintaining neutral pH levels to prevent aggressive conditions. Employing corrosion-resistant brass alloys with low zinc content and proper heat treatment enhances material durability by limiting dezincification effects. Regular inspection and stress-relieving processes like annealing mitigate residual stresses, significantly reducing the risk of SCC in brass components.

Selecting Brass Materials for Corrosion Resistance

Selecting brass materials with low zinc content and added corrosion inhibitors enhances resistance to dezincification, a common form of selective leaching that degrades brass in corrosive environments. Stress corrosion cracking in brass can be mitigated by choosing alloys with balanced copper and zinc ratios, improved tensile strength, and minimal residual stresses. Opting for dezincification-resistant (DZR) brass alloys ensures durability in plumbing and marine applications prone to both corrosion types.

Dezincification vs Stress Corrosion Infographic

materialdif.com

materialdif.com