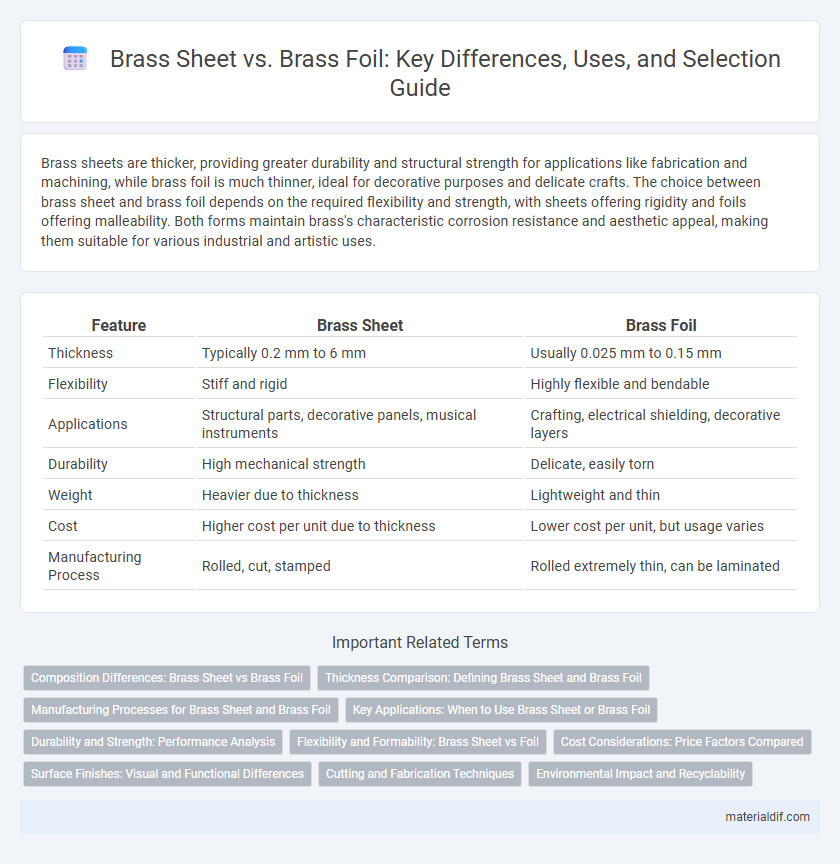

Brass sheets are thicker, providing greater durability and structural strength for applications like fabrication and machining, while brass foil is much thinner, ideal for decorative purposes and delicate crafts. The choice between brass sheet and brass foil depends on the required flexibility and strength, with sheets offering rigidity and foils offering malleability. Both forms maintain brass's characteristic corrosion resistance and aesthetic appeal, making them suitable for various industrial and artistic uses.

Table of Comparison

| Feature | Brass Sheet | Brass Foil |

|---|---|---|

| Thickness | Typically 0.2 mm to 6 mm | Usually 0.025 mm to 0.15 mm |

| Flexibility | Stiff and rigid | Highly flexible and bendable |

| Applications | Structural parts, decorative panels, musical instruments | Crafting, electrical shielding, decorative layers |

| Durability | High mechanical strength | Delicate, easily torn |

| Weight | Heavier due to thickness | Lightweight and thin |

| Cost | Higher cost per unit due to thickness | Lower cost per unit, but usage varies |

| Manufacturing Process | Rolled, cut, stamped | Rolled extremely thin, can be laminated |

Composition Differences: Brass Sheet vs Brass Foil

Brass sheets typically consist of a thicker alloy composition, often combining copper with zinc in varying ratios such as 70/30 or 60/40, resulting in greater durability and strength. Brass foil, on the other hand, is composed of thinner layers with a higher copper content, enhancing its flexibility and malleability for detailed applications. These compositional differences affect the physical properties and suitability of brass sheets and foils for industrial versus decorative uses.

Thickness Comparison: Defining Brass Sheet and Brass Foil

Brass sheets typically range in thickness from 0.5mm to 6mm, offering rigid structural support for applications like architectural components and mechanical parts. Brass foil is much thinner, usually measuring between 0.06mm and 0.5mm, making it ideal for delicate uses such as decorative inlays and electromagnetic shielding. Understanding these thickness differences is crucial for selecting the right material based on durability and flexibility requirements.

Manufacturing Processes for Brass Sheet and Brass Foil

Brass sheets are typically produced through hot rolling or cold rolling processes, which involve passing heated or room-temperature brass slabs through rollers to achieve desired thickness and mechanical properties. Brass foils, by contrast, undergo extensive cold rolling and annealing cycles to attain extremely thin gauges with high flexibility and surface finish quality. The precision and control in rolling and heat treatment determine the brass material's final thickness, strength, and application suitability, differentiating sheets used in structural contexts from foils applied in decorative or shielding uses.

Key Applications: When to Use Brass Sheet or Brass Foil

Brass sheets are ideal for structural applications requiring durability and thickness, such as architectural panels, machine parts, and musical instruments, due to their rigidity and ease of machining. Brass foil is preferred for decorative purposes, crafting, and electronic shielding, where flexibility, thinness, and precise layering are essential. Choosing between brass sheet and foil depends on the balance between mechanical strength and malleability needed for specific engineering or artistic projects.

Durability and Strength: Performance Analysis

Brass sheets typically offer greater thickness and structural integrity compared to brass foil, resulting in superior durability and enhanced resistance to deformation under stress. The denser composition of brass sheets provides improved tensile strength, making them ideal for applications demanding long-term performance and mechanical stability. In contrast, brass foil, being significantly thinner, sacrifices strength and durability for flexibility and ease of shaping, limiting its use in high-stress environments.

Flexibility and Formability: Brass Sheet vs Foil

Brass foil offers superior flexibility compared to brass sheets due to its significantly thinner gauge, enabling intricate bending and shaping without cracking. Brass sheets provide greater structural integrity and are better suited for applications requiring sturdier, less malleable materials. Selecting between the two depends on the specific formability requirements and the degree of flexibility needed in the final product.

Cost Considerations: Price Factors Compared

Brass sheets generally cost less per unit area compared to brass foil due to their greater thickness and ease of manufacturing, which reduces production expenses. Brass foil, being much thinner and requiring more precise processing, often incurs higher costs despite using less material. Price factors also depend on alloy composition, finish, and supplier, but the thinner gauge and specialized uses of brass foil usually lead to a premium over standard brass sheets.

Surface Finishes: Visual and Functional Differences

Brass sheets typically have smoother, more uniform surface finishes ideal for structural and decorative applications, while brass foil offers ultra-thin, flexible layers with slightly varied textures suitable for intricate detailing and layering. The surface finish of brass sheets enhances scratch resistance and durability, whereas the brass foil's finish emphasizes malleability and ease of embossing or stamping. Visual differences include the sheet's consistent sheen versus the foil's sometimes more lustrous, reflective quality due to its thinness.

Cutting and Fabrication Techniques

Brass sheets are thicker and require cutting methods such as shearing, laser cutting, or CNC machining for precise fabrication, making them suitable for structural components. Brass foil, much thinner, is typically cut with scissors, knives, or chemical etching, allowing for delicate and detailed designs. Selecting the appropriate cutting and fabrication technique depends on the material thickness and the intended application of the brass product.

Environmental Impact and Recyclability

Brass sheets, thicker and more durable, generally have a longer lifecycle and higher recyclability rate compared to thinner brass foils, which can be more challenging to recycle due to their delicate nature and frequent use in single-use applications. The production of brass sheets typically consumes more raw materials and energy, but their robustness reduces the need for frequent replacement, mitigating overall environmental impact. Choosing brass sheets over foil enhances sustainability by facilitating easier recycling processes and reducing waste generation in manufacturing and end-of-life disposal.

Brass Sheet vs Brass Foil Infographic

materialdif.com

materialdif.com