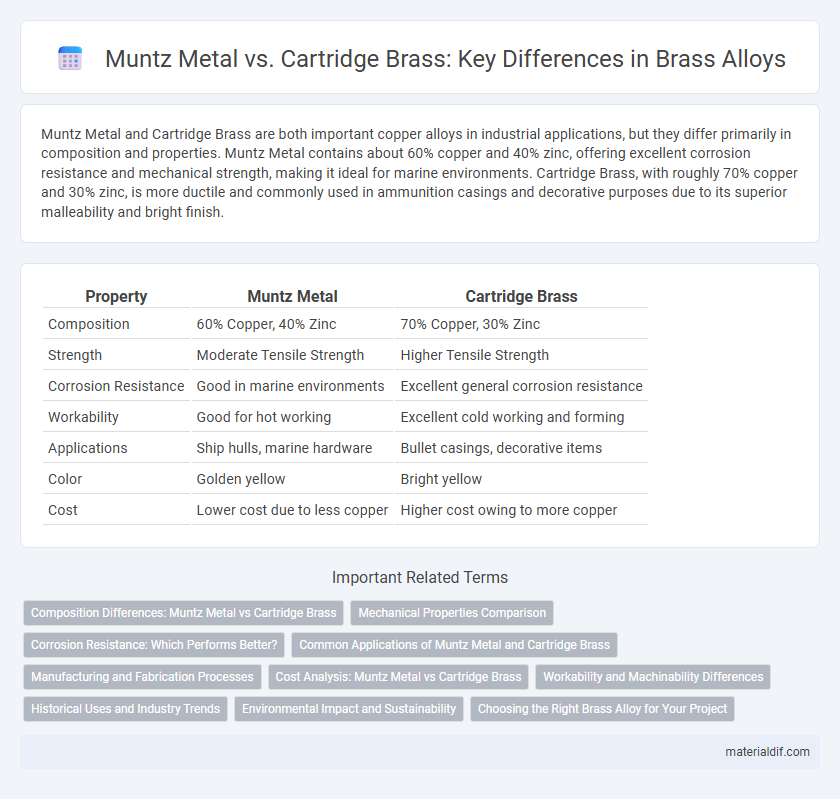

Muntz Metal and Cartridge Brass are both important copper alloys in industrial applications, but they differ primarily in composition and properties. Muntz Metal contains about 60% copper and 40% zinc, offering excellent corrosion resistance and mechanical strength, making it ideal for marine environments. Cartridge Brass, with roughly 70% copper and 30% zinc, is more ductile and commonly used in ammunition casings and decorative purposes due to its superior malleability and bright finish.

Table of Comparison

| Property | Muntz Metal | Cartridge Brass |

|---|---|---|

| Composition | 60% Copper, 40% Zinc | 70% Copper, 30% Zinc |

| Strength | Moderate Tensile Strength | Higher Tensile Strength |

| Corrosion Resistance | Good in marine environments | Excellent general corrosion resistance |

| Workability | Good for hot working | Excellent cold working and forming |

| Applications | Ship hulls, marine hardware | Bullet casings, decorative items |

| Color | Golden yellow | Bright yellow |

| Cost | Lower cost due to less copper | Higher cost owing to more copper |

Composition Differences: Muntz Metal vs Cartridge Brass

Muntz Metal typically consists of 60% copper and 40% zinc, offering high strength and corrosion resistance ideal for marine applications. Cartridge Brass contains approximately 70% copper and 30% zinc, providing superior ductility and malleability suited for ammunition casings. The varying copper-to-zinc ratios directly influence the mechanical properties and corrosion resistance of each brass alloy.

Mechanical Properties Comparison

Muntz Metal, composed of approximately 60% copper and 40% zinc, offers higher tensile strength around 380 MPa compared to Cartridge Brass, which typically contains 70% copper and 30% zinc with tensile strength near 350 MPa. Muntz Metal exhibits superior hardness and wear resistance, making it suitable for applications requiring robustness under mechanical stress, whereas Cartridge Brass provides better ductility and corrosion resistance. The differences in yield strength and elongation percentage highlight Muntz Metal's enhanced durability versus Cartridge Brass's flexibility in forming processes.

Corrosion Resistance: Which Performs Better?

Muntz Metal, an alloy of approximately 60% copper and 40% zinc, offers superior corrosion resistance compared to Cartridge Brass, which typically contains 70% copper and 30% zinc. The higher zinc content in Cartridge Brass increases susceptibility to dezincification, especially in marine and acidic environments, whereas Muntz Metal's composition enhances resilience against corrosion. Therefore, Muntz Metal is often preferred in applications requiring prolonged exposure to harsh conditions due to its better corrosion resistance performance.

Common Applications of Muntz Metal and Cartridge Brass

Muntz Metal, composed primarily of 60% copper and 40% zinc, is widely used in maritime applications such as ship hulls and decorative architectural elements due to its excellent corrosion resistance and durability. Cartridge Brass, with about 70% copper and 30% zinc, is preferred for manufacturing ammunition casings, electrical connectors, and musical instruments because of its high ductility and strength. Both alloys serve distinct purposes in engineering and industrial sectors based on their specific mechanical properties and corrosion resistance.

Manufacturing and Fabrication Processes

Muntz Metal, an alloy of approximately 60% copper and 40% zinc, is favored for manufacturing due to its excellent corrosion resistance and high strength, enabling robust fabrication through hot rolling and forging. Cartridge Brass, composed of roughly 70% copper and 30% zinc, offers superior ductility and workability, making it ideal for precise stamping and deep drawing processes in cartridge production. Differences in zinc content influence their thermal conductivity and machinability, impacting tool life and efficiency during the fabrication stages.

Cost Analysis: Muntz Metal vs Cartridge Brass

Muntz Metal, composed of approximately 60% copper and 40% zinc, generally offers a lower material cost compared to Cartridge Brass, which typically contains 70% copper and 30% zinc. The higher zinc content in Muntz Metal reduces raw material expenses, making it more cost-effective for large-scale manufacturing. However, Cartridge Brass's superior machinability and corrosion resistance can lower long-term operational costs despite its higher initial price.

Workability and Machinability Differences

Muntz Metal, an alloy of approximately 60% copper and 40% zinc, offers excellent workability due to its moderate hardness and ductility, making it ideal for forming and bending applications. Cartridge Brass, with a higher copper content around 70% and 30% zinc, exhibits superior machinability because of its uniform grain structure and reduced springiness, allowing for precision cutting and minimal tool wear. While both alloys maintain corrosion resistance, Muntz Metal is preferred for stamping and forming, whereas Cartridge Brass excels in processes requiring detailed machining and fine tolerances.

Historical Uses and Industry Trends

Muntz metal, an alloy consisting of approximately 60% copper and 40% zinc, was historically favored for maritime applications such as ship hulls and marine hardware due to its corrosion resistance and strength. Cartridge brass, with a higher copper content around 70%, became the standard in ammunition manufacturing and musical instruments because of its excellent formability and durability. Industry trends show a sustained preference for cartridge brass in precision applications, while Muntz metal remains important in marine and architectural uses due to its robustness and cost-effectiveness.

Environmental Impact and Sustainability

Muntz Metal, an alloy composed primarily of copper and zinc, offers enhanced corrosion resistance which extends the lifespan of products and reduces the need for frequent replacement, thereby lowering overall environmental impact. Cartridge Brass, with a higher zinc content, is more prone to corrosion and wear, potentially leading to increased resource consumption and waste generation over time. The recyclability of both alloys supports sustainability, but Muntz Metal's durability favors longer material cycles and reduced ecological footprint in manufacturing and usage.

Choosing the Right Brass Alloy for Your Project

Muntz Metal, an alloy composed of roughly 60% copper and 40% zinc, offers excellent corrosion resistance and strength, making it ideal for marine applications and structural components. Cartridge Brass, containing approximately 70% copper and 30% zinc, provides superior ductility and formability, which is preferred for precision machining and decorative purposes. Selecting between Muntz Metal and Cartridge Brass depends on project requirements such as environmental exposure, mechanical strength, and manufacturing processes.

Muntz Metal vs Cartridge Brass Infographic

materialdif.com

materialdif.com