Lead-free brass offers a safer alternative to standard brass by eliminating lead content, reducing health risks associated with lead exposure. It maintains excellent machinability and corrosion resistance, making it suitable for plumbing and food-grade applications. Standard brass, while durable and cost-effective, may pose environmental and health concerns due to its lead content, especially in potable water systems.

Table of Comparison

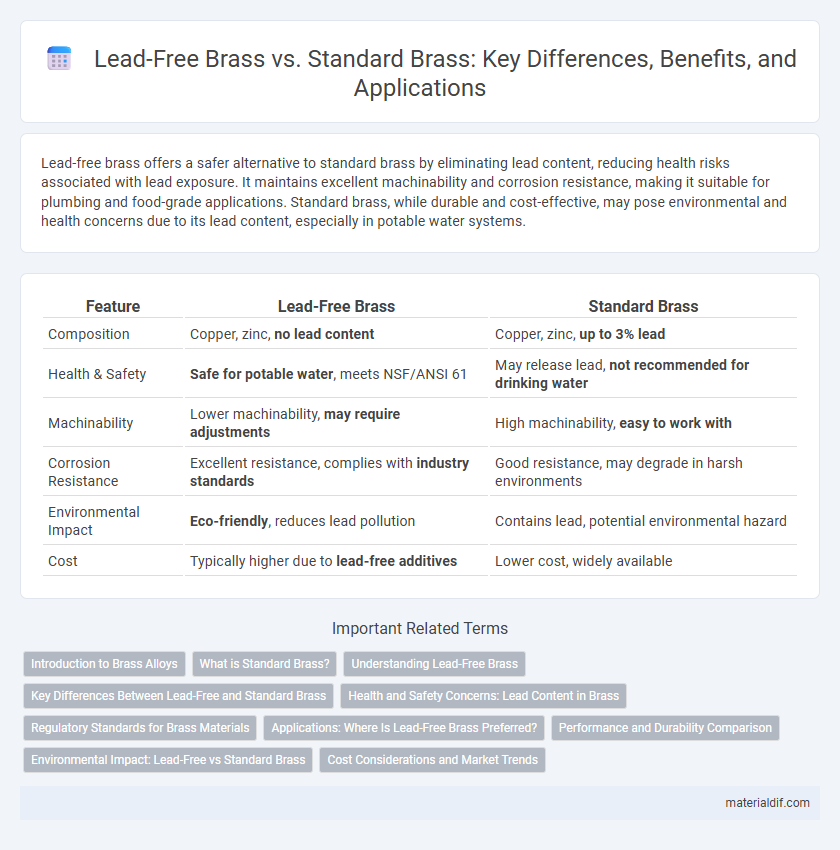

| Feature | Lead-Free Brass | Standard Brass |

|---|---|---|

| Composition | Copper, zinc, no lead content | Copper, zinc, up to 3% lead |

| Health & Safety | Safe for potable water, meets NSF/ANSI 61 | May release lead, not recommended for drinking water |

| Machinability | Lower machinability, may require adjustments | High machinability, easy to work with |

| Corrosion Resistance | Excellent resistance, complies with industry standards | Good resistance, may degrade in harsh environments |

| Environmental Impact | Eco-friendly, reduces lead pollution | Contains lead, potential environmental hazard |

| Cost | Typically higher due to lead-free additives | Lower cost, widely available |

Introduction to Brass Alloys

Lead-free brass alloys eliminate lead content to enhance environmental safety and comply with regulatory standards, often substituting lead with elements like silicon or bismuth. Standard brass, typically composed of copper and zinc with small percentages of lead, offers excellent machinability but raises concerns due to lead's toxicity. Advances in lead-free brass maintain mechanical strength and corrosion resistance while promoting safer use in plumbing and food-contact applications.

What is Standard Brass?

Standard brass is an alloy primarily composed of copper and zinc, typically containing small amounts of lead to improve machinability and durability. This traditional composition enhances the ease of manufacturing but raises environmental and health concerns due to lead content. Standard brass is widely used in plumbing, automotive, and electrical applications where strength and corrosion resistance are essential.

Understanding Lead-Free Brass

Lead-free brass is an alloy primarily composed of copper, zinc, and other metals but contains less than 0.25% lead, meeting stringent health and environmental standards. Unlike standard brass, which often includes higher lead content to improve machinability, lead-free brass is engineered to maintain corrosion resistance and durability while eliminating lead-related toxicity. This makes lead-free brass particularly suitable for plumbing, potable water systems, and food-grade applications where safety and compliance with regulations such as the Safe Drinking Water Act are critical.

Key Differences Between Lead-Free and Standard Brass

Lead-free brass typically contains less than 0.25% lead, making it safer for potable water applications compared to standard brass, which can contain up to 3% lead. Standard brass offers superior machinability and corrosion resistance due to its lead content, but lead-free brass complies with stricter environmental regulations such as the Safe Drinking Water Act. The key differences involve health safety, regulatory compliance, and material performance, with lead-free brass being preferred in plumbing and food industry contexts.

Health and Safety Concerns: Lead Content in Brass

Lead-free brass significantly reduces health risks associated with lead exposure, making it a safer option in plumbing and potable water systems. Standard brass contains varying amounts of lead, which can leach into drinking water, posing serious health concerns such as neurological damage and developmental issues. Regulatory standards like the Safe Drinking Water Act limit lead content in brass used for potable water applications to ensure consumer safety.

Regulatory Standards for Brass Materials

Lead-free brass complies with stringent regulatory standards such as the U.S. Safe Drinking Water Act (SDWA) and the European Union's REACH regulation, limiting lead content to below 0.25% or 0.1% respectively. Standard brass often contains higher lead content, typically around 2-3%, which enhances machinability but fails to meet these lead reduction standards. Regulatory compliance drives the adoption of lead-free brass in applications requiring potable water safety and environmental health considerations.

Applications: Where Is Lead-Free Brass Preferred?

Lead-free brass is preferred in applications involving potable water systems, plumbing fixtures, and food processing equipment due to strict regulatory standards on lead content, ensuring safer drinking water and consumer products. Standard brass, containing small amounts of lead for machinability, is often used in industrial applications, electrical components, and decorative items where lead content is less restrictive. The shift towards lead-free brass aligns with environmental regulations such as the Safe Drinking Water Act (SDWA) and NSF/ANSI 61 certification, emphasizing health and safety in public and residential infrastructure.

Performance and Durability Comparison

Lead-free brass offers enhanced corrosion resistance and improved environmental safety compared to standard brass, which contains lead for machinability but poses health risks. Performance-wise, lead-free brass maintains comparable strength and machinability, making it suitable for plumbing and potable water applications. Durability in lead-free brass often surpasses standard brass due to reduced lead leaching, ensuring longer service life in sensitive environments.

Environmental Impact: Lead-Free vs Standard Brass

Lead-free brass significantly reduces environmental contamination by eliminating toxic lead, which can leach into soil and water during production and disposal of standard brass. Standard brass typically contains 2-3% lead to improve machinability but poses risks to ecosystems and human health through lead pollution. Choosing lead-free brass supports sustainable manufacturing practices and complies with stricter environmental regulations aimed at reducing heavy metal pollution.

Cost Considerations and Market Trends

Lead-free brass typically incurs higher manufacturing costs due to stricter regulatory compliance and the use of alternative alloying elements, impacting its price relative to standard brass. Market trends show increasing demand for lead-free brass driven by health and environmental regulations, promoting innovation but also causing potential price premiums. Standard brass remains more cost-effective for applications without stringent lead restrictions, maintaining steady demand in traditional industrial sectors.

Lead-Free Brass vs Standard Brass Infographic

materialdif.com

materialdif.com