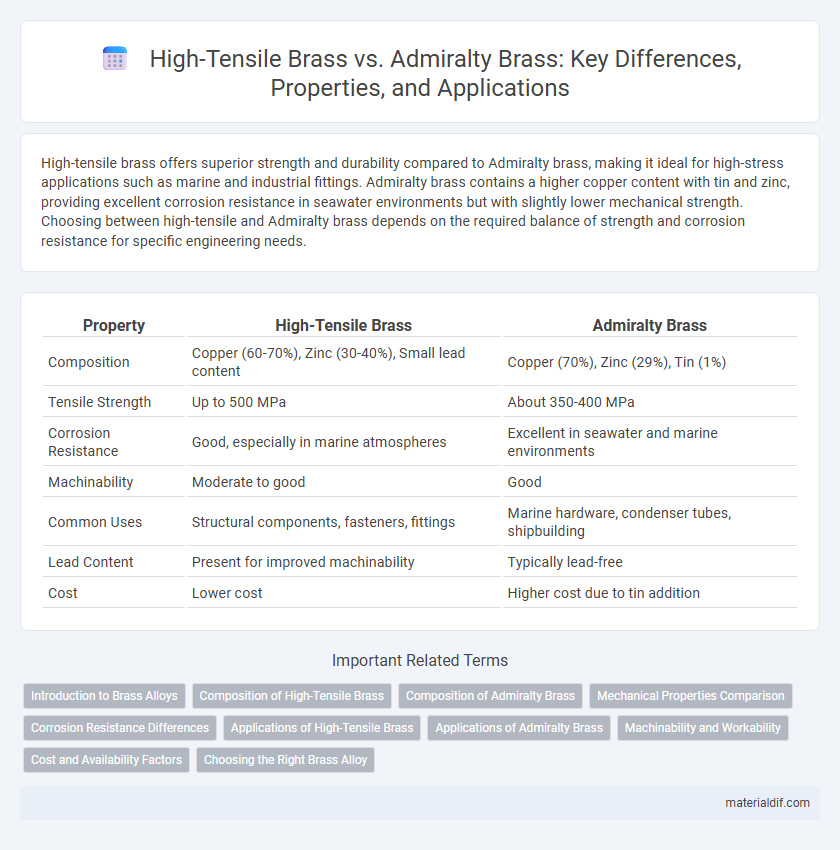

High-tensile brass offers superior strength and durability compared to Admiralty brass, making it ideal for high-stress applications such as marine and industrial fittings. Admiralty brass contains a higher copper content with tin and zinc, providing excellent corrosion resistance in seawater environments but with slightly lower mechanical strength. Choosing between high-tensile and Admiralty brass depends on the required balance of strength and corrosion resistance for specific engineering needs.

Table of Comparison

| Property | High-Tensile Brass | Admiralty Brass |

|---|---|---|

| Composition | Copper (60-70%), Zinc (30-40%), Small lead content | Copper (70%), Zinc (29%), Tin (1%) |

| Tensile Strength | Up to 500 MPa | About 350-400 MPa |

| Corrosion Resistance | Good, especially in marine atmospheres | Excellent in seawater and marine environments |

| Machinability | Moderate to good | Good |

| Common Uses | Structural components, fasteners, fittings | Marine hardware, condenser tubes, shipbuilding |

| Lead Content | Present for improved machinability | Typically lead-free |

| Cost | Lower cost | Higher cost due to tin addition |

Introduction to Brass Alloys

High-tensile brass and Admiralty brass are both copper-zinc alloys renowned for their strength and corrosion resistance, but they differ significantly in composition and applications. High-tensile brass typically contains higher zinc content and sometimes small amounts of lead or tin to enhance machinability and mechanical properties, making it ideal for heavy-duty components requiring durability. Admiralty brass, composed primarily of copper, zinc, and tin, offers superior resistance to seawater corrosion, making it the preferred choice for marine and naval applications.

Composition of High-Tensile Brass

High-tensile brass primarily consists of about 60-70% copper and 30-40% zinc, with small amounts of lead or tin added to improve machinability and strength. This composition enhances tensile strength and corrosion resistance compared to standard copper alloys, making it suitable for applications requiring durability under mechanical stress. Variations in zinc content allow for adjustments in hardness and elasticity, optimizing high-tensile brass for industrial uses.

Composition of Admiralty Brass

Admiralty Brass primarily consists of about 70% copper, 29% zinc, and 1% tin, which enhances its corrosion resistance in marine environments. This composition differentiates it from high-tensile brass, which typically has a higher zinc content and lacks tin, resulting in increased strength but reduced resistance to seawater corrosion. The presence of tin in Admiralty Brass significantly improves its durability against saltwater, making it ideal for marine hardware and fittings.

Mechanical Properties Comparison

High-tensile brass exhibits superior tensile strength, typically ranging from 600 to 750 MPa, compared to Admiralty brass, which generally has tensile strength around 350 to 450 MPa. Admiralty brass offers better corrosion resistance and machinability, making it suitable for marine applications, whereas high-tensile brass is preferred in structural uses requiring enhanced load-bearing capacity. Yield strength in high-tensile brass can reach up to 500 MPa, significantly higher than the approximately 250 MPa yield strength of Admiralty brass.

Corrosion Resistance Differences

High-tensile brass offers superior mechanical strength but generally exhibits lower corrosion resistance compared to Admiralty brass, which contains a higher proportion of tin and zinc to enhance its durability in marine environments. Admiralty brass's unique alloy composition provides excellent resistance to dezincification and pitting corrosion, making it ideal for seawater applications. In contrast, high-tensile brass is better suited for structural uses where strength is prioritized over corrosion resistance.

Applications of High-Tensile Brass

High-tensile brass is widely used in applications requiring superior strength and corrosion resistance, such as marine fasteners, automotive components, and industrial valve parts. Its enhanced tensile strength compared to Admiralty brass makes it ideal for high-stress environments and heavy-duty machinery. This brass alloy excels in fabrication of springs, electrical connectors, and precision instruments where durability and mechanical reliability are critical.

Applications of Admiralty Brass

Admiralty brass, known for its high corrosion resistance and excellent seawater durability, is widely used in marine applications such as shipbuilding, offshore platforms, and desalination plants. Its composition, typically containing copper, zinc, and tin, provides enhanced resistance to biofouling and stress corrosion cracking. This makes Admiralty brass ideal for heat exchangers, condenser tubes, and pump components exposed to harsh aquatic environments.

Machinability and Workability

High-tensile brass offers superior strength and corrosion resistance but has lower machinability compared to Admiralty brass, which is known for its excellent workability and ease of machining. Admiralty brass contains a higher copper content and a small amount of arsenic, enhancing its machinability and suitability for intricate components. High-tensile brass, with its greater zinc content and harder structure, requires specialized tools and slower machining speeds to avoid tool wear and achieve precise finishes.

Cost and Availability Factors

High-tensile brass offers superior strength and durability compared to Admiralty brass, making it ideal for demanding applications but often comes with higher costs due to alloying elements like aluminum and iron. Admiralty brass, known for its excellent corrosion resistance and moderate strength, is generally more cost-effective and widely available, especially in marine hardware and fittings. Availability of high-tensile brass may be limited in some regions due to specialized manufacturing processes, whereas Admiralty brass benefits from established global supply chains ensuring easier access and lower lead times.

Choosing the Right Brass Alloy

High-Tensile Brass offers superior strength and durability, making it ideal for applications requiring high mechanical performance and resistance to wear. Admiralty Brass provides excellent corrosion resistance in marine environments due to its specific composition with tin and zinc. Selecting the right brass alloy depends on balancing mechanical strength with environmental factors such as exposure to seawater or mechanical stress.

High-Tensile Brass vs Admiralty Brass Infographic

materialdif.com

materialdif.com