Brass plating offers an affordable, corrosion-resistant surface layer that enhances the appearance of base metals while maintaining durability. Solid brass provides superior strength, longevity, and natural antimicrobial properties, making it ideal for heavy-use applications. Choosing between brass plating and solid brass depends on budget, desired aesthetics, and functional requirements.

Table of Comparison

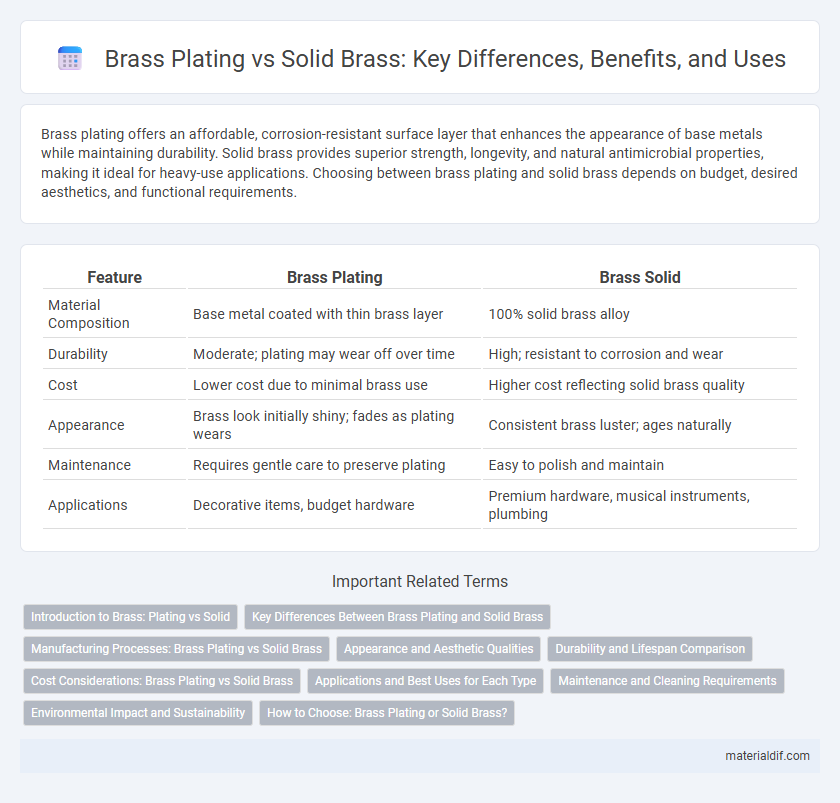

| Feature | Brass Plating | Brass Solid |

|---|---|---|

| Material Composition | Base metal coated with thin brass layer | 100% solid brass alloy |

| Durability | Moderate; plating may wear off over time | High; resistant to corrosion and wear |

| Cost | Lower cost due to minimal brass use | Higher cost reflecting solid brass quality |

| Appearance | Brass look initially shiny; fades as plating wears | Consistent brass luster; ages naturally |

| Maintenance | Requires gentle care to preserve plating | Easy to polish and maintain |

| Applications | Decorative items, budget hardware | Premium hardware, musical instruments, plumbing |

Introduction to Brass: Plating vs Solid

Brass plating involves applying a thin layer of brass onto a base metal, offering an attractive finish with enhanced corrosion resistance while maintaining cost-efficiency. Solid brass, composed entirely of brass alloy, provides superior durability, strength, and natural antimicrobial properties, making it ideal for high-contact applications. Understanding the differences in composition, longevity, and maintenance is crucial when choosing between brass plating and solid brass for specific uses.

Key Differences Between Brass Plating and Solid Brass

Brass plating involves depositing a thin layer of brass onto a base metal, offering a brass-like appearance with cost efficiency but limited durability compared to solid brass. Solid brass is a homogeneous alloy composed primarily of copper and zinc, providing superior strength, corrosion resistance, and longevity. Key differences include the plating's susceptibility to wear and tarnish over time, whereas solid brass maintains its structural integrity and aesthetic appeal under heavy use.

Manufacturing Processes: Brass Plating vs Solid Brass

Brass plating involves applying a thin layer of brass onto a base metal through electroplating, offering cost-effective corrosion resistance and aesthetic appeal while enabling precise finishes. Solid brass manufacturing entails casting or machining from a solid brass alloy, providing superior durability, strength, and uniform material properties essential for high-stress applications. The choice between brass plating and solid brass hinges on factors like budget, application requirements, and desired longevity, with plating favoring decorative use and solid brass suited for structural components.

Appearance and Aesthetic Qualities

Brass plating offers a polished, uniform surface that enhances the visual appeal of items with a shiny, smooth finish but can wear over time, revealing underlying materials. Solid brass provides a rich, warm golden tone with natural variations and patina development, contributing to a unique and authentic aesthetic. The choice between brass plating and solid brass significantly impacts durability and long-term appearance, with solid brass maintaining its look through oxidation and aging.

Durability and Lifespan Comparison

Brass plating offers a cost-effective aesthetic but tends to wear off over time, exposing the underlying material to corrosion and reducing overall durability. Solid brass components exhibit superior strength and resistance to tarnish, ensuring a significantly longer lifespan even in high-usage or harsh environments. Choosing solid brass over brass plating results in better performance and longevity, especially for applications requiring frequent handling or exposure to moisture.

Cost Considerations: Brass Plating vs Solid Brass

Brass plating offers a cost-effective alternative to solid brass by using a thin layer of brass over less expensive base metals, significantly reducing material expenses while maintaining an attractive appearance. Solid brass, though more costly due to its pure metal composition, provides superior durability and resistance to corrosion, extending the lifespan of products. Choosing between brass plating and solid brass depends on budget constraints and the required longevity for applications such as fixtures, hardware, or decorative items.

Applications and Best Uses for Each Type

Brass plating is ideal for decorative applications such as jewelry, musical instruments, and hardware, offering corrosion resistance and a polished appearance while being cost-effective. Solid brass is preferred for industrial components, plumbing fixtures, and valves where durability, strength, and thermal conductivity are critical. Choosing between brass plating and solid brass depends on required mechanical properties, environmental exposure, and budget constraints in the intended application.

Maintenance and Cleaning Requirements

Brass plating requires regular polishing and careful cleaning to prevent tarnishing and maintain its shiny appearance, while solid brass naturally develops a patina that can be cleaned gently with mild soap and water. Solid brass is more durable and less prone to surface damage, making maintenance easier over time compared to plated brass, which may flake or wear off. Using non-abrasive cleaners preserves the quality of both brass plating and solid brass, but solid brass offers longer-lasting aesthetic and functional benefits.

Environmental Impact and Sustainability

Brass plating involves coating a base metal with a thin layer of brass, which may introduce environmental concerns due to toxic chemicals used in electroplating processes and wastewater treatment challenges. Solid brass, being a homogeneous alloy of copper and zinc, generally offers greater sustainability by eliminating plating waste and providing better recyclability at the end of its lifecycle. Choosing solid brass reduces environmental impact through longer product durability and fewer chemical pollutants compared to brass-plated alternatives.

How to Choose: Brass Plating or Solid Brass?

Choosing between brass plating and solid brass depends on durability, cost, and application. Brass plating offers a cost-effective, corrosion-resistant surface ideal for decorative purposes, while solid brass provides superior strength, longevity, and natural antimicrobial properties suited for high-use hardware. Prioritize solid brass for structural components and plating for aesthetic enhancements or budget-conscious projects.

Brass Plating vs Brass Solid Infographic

materialdif.com

materialdif.com