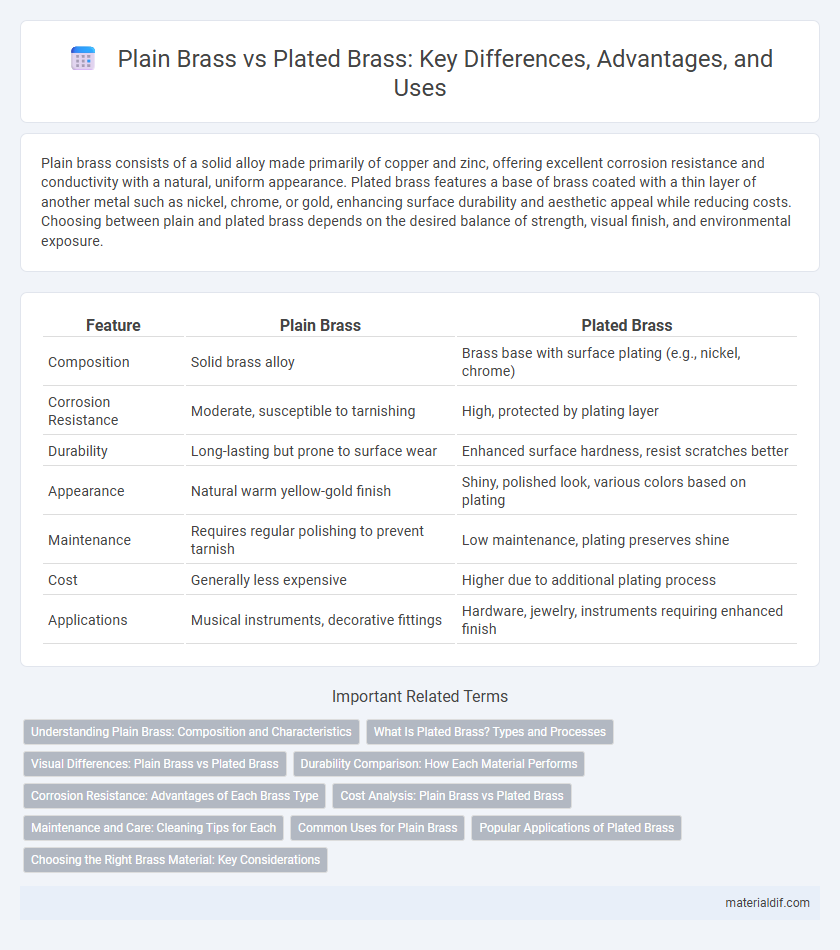

Plain brass consists of a solid alloy made primarily of copper and zinc, offering excellent corrosion resistance and conductivity with a natural, uniform appearance. Plated brass features a base of brass coated with a thin layer of another metal such as nickel, chrome, or gold, enhancing surface durability and aesthetic appeal while reducing costs. Choosing between plain and plated brass depends on the desired balance of strength, visual finish, and environmental exposure.

Table of Comparison

| Feature | Plain Brass | Plated Brass |

|---|---|---|

| Composition | Solid brass alloy | Brass base with surface plating (e.g., nickel, chrome) |

| Corrosion Resistance | Moderate, susceptible to tarnishing | High, protected by plating layer |

| Durability | Long-lasting but prone to surface wear | Enhanced surface hardness, resist scratches better |

| Appearance | Natural warm yellow-gold finish | Shiny, polished look, various colors based on plating |

| Maintenance | Requires regular polishing to prevent tarnish | Low maintenance, plating preserves shine |

| Cost | Generally less expensive | Higher due to additional plating process |

| Applications | Musical instruments, decorative fittings | Hardware, jewelry, instruments requiring enhanced finish |

Understanding Plain Brass: Composition and Characteristics

Plain brass consists primarily of copper and zinc, typically around 60-70% copper and 30-40% zinc, offering excellent machinability and corrosion resistance. Its solid composition provides consistent mechanical properties, including good strength and ductility, making it ideal for manufacturing durable components. Unlike plated brass, plain brass does not have an additional surface coating, which affects its appearance and resistance to wear and oxidation over time.

What Is Plated Brass? Types and Processes

Plated brass is a base metal composed primarily of copper and zinc coated with a thin layer of another metal, such as nickel, chrome, or gold, to enhance appearance, corrosion resistance, and durability. Common plating processes include electroplating, where an electric current deposits the plating metal, and electroless plating, which uses chemical reactions without electricity for a uniform coating. Types of plated brass vary by the plating metal, each offering specific benefits: nickel plating provides corrosion resistance, chrome plating enhances surface hardness and shine, and gold plating adds a layer of corrosion protection and aesthetic appeal.

Visual Differences: Plain Brass vs Plated Brass

Plain brass features a warm, golden-yellow tone with a natural patina that can develop over time, giving it an antique or aged appearance. Plated brass, on the other hand, has a uniform, highly reflective surface often achieved through nickel, chrome, or gold plating, resulting in a brighter and more polished look. The visual contrast between the two lies in plain brass's organic, slightly matte finish versus plated brass's smooth, glossy, and corrosion-resistant coating.

Durability Comparison: How Each Material Performs

Plain brass offers superior durability due to its solid alloy composition, providing excellent resistance to corrosion, wear, and mechanical stress in various environments. Plated brass, while visually appealing, relies on a thin layer of metal such as nickel or chrome, which can wear off over time, reducing its overall durability and exposing the underlying brass to corrosion and damage. Choosing plain brass ensures long-term strength and resistance, whereas plated brass requires more maintenance to preserve its surface integrity.

Corrosion Resistance: Advantages of Each Brass Type

Plain brass offers inherent corrosion resistance due to its copper and zinc alloy composition, making it suitable for indoor applications where exposure to moisture is limited. Plated brass enhances corrosion resistance through a protective coating such as nickel or chrome, providing superior durability in harsh environments and preventing oxidation more effectively than plain brass. Each type benefits specific uses: plain brass excels in cost-effectiveness and natural patina development, while plated brass delivers increased longevity and resistance in high-humidity or marine conditions.

Cost Analysis: Plain Brass vs Plated Brass

Plain brass generally incurs higher upfront costs due to its solid metal composition and durable properties, making it suitable for long-term applications. Plated brass offers a cost-effective alternative by combining a less expensive base metal with a thin outer layer of brass, reducing material expenses while maintaining a similar aesthetic. Cost analysis must consider factors such as durability, maintenance requirements, and application-specific performance to determine the most economical choice between plain and plated brass.

Maintenance and Care: Cleaning Tips for Each

Plain brass requires regular polishing with a brass cleaner or a mixture of lemon juice and baking soda to prevent tarnish and maintain its natural shine. Plated brass needs gentle cleaning with a soft cloth and mild soapy water to avoid damaging the thin plating layer while removing surface dirt. Avoid abrasive materials and harsh chemicals on both types to extend the lifespan of the finish and preserve aesthetic appeal.

Common Uses for Plain Brass

Plain brass, composed primarily of copper and zinc, is widely used in plumbing fittings, musical instruments, and decorative hardware due to its corrosion resistance and malleability. Its antimicrobial properties make it a preferred material for door handles, locks, and faucets in healthcare and public settings. The alloy's durability and electrical conductivity also enable applications in electrical connectors and automotive components.

Popular Applications of Plated Brass

Plated brass is widely used in decorative hardware, plumbing fixtures, and musical instruments due to its enhanced corrosion resistance and aesthetic appeal. Common plating materials like nickel, chrome, and gold improve durability while providing a polished finish essential for consumer electronics and automotive trim. These applications benefit from plated brass's ability to combine the strength of brass with the protective and visual advantages of metal plating.

Choosing the Right Brass Material: Key Considerations

Selecting the right brass material involves assessing factors such as corrosion resistance, durability, and aesthetic appeal. Plain brass offers excellent machinability and natural corrosion resistance due to its high copper content, making it ideal for applications exposed to moisture. Plated brass provides enhanced surface protection and a polished finish, suitable for decorative purposes where long-lasting appearance and resistance to tarnishing are crucial.

Plain Brass vs Plated Brass Infographic

materialdif.com

materialdif.com