Dezincification-resistant brass contains additives such as arsenic, phosphorus, or antimony to significantly reduce the leaching of zinc, enhancing its corrosion resistance compared to standard brass. Standard brass, composed primarily of copper and zinc, is more susceptible to dezincification, which deteriorates its mechanical strength and surface integrity in aggressive environments. Using dezincification-resistant brass ensures longer-lasting performance in plumbing and marine applications where exposure to water and corrosive agents is common.

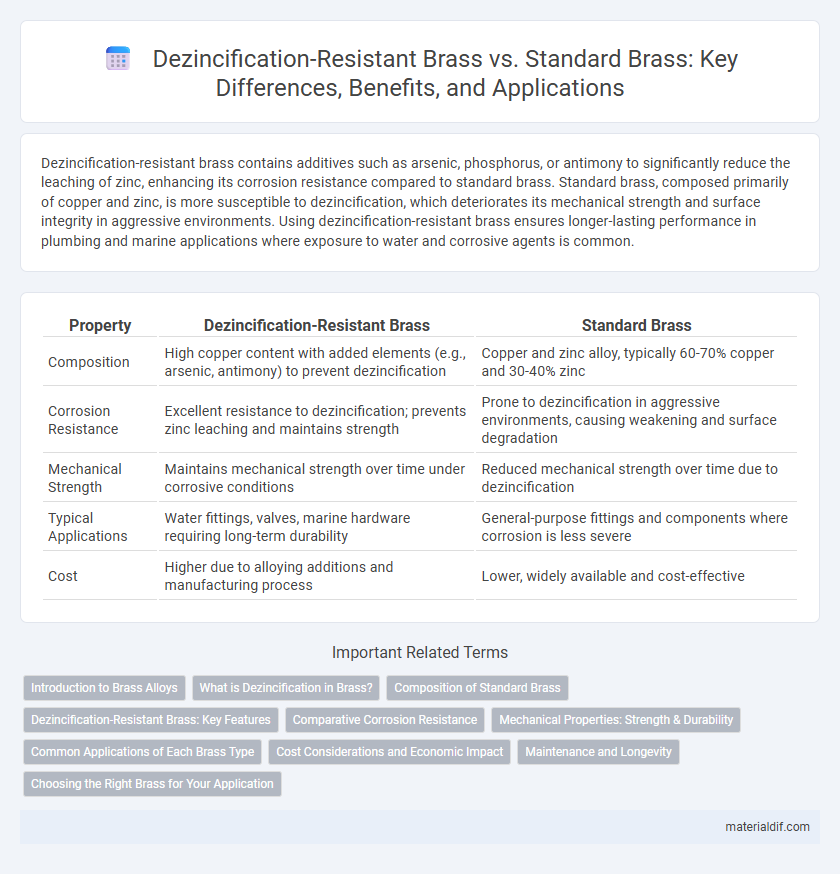

Table of Comparison

| Property | Dezincification-Resistant Brass | Standard Brass |

|---|---|---|

| Composition | High copper content with added elements (e.g., arsenic, antimony) to prevent dezincification | Copper and zinc alloy, typically 60-70% copper and 30-40% zinc |

| Corrosion Resistance | Excellent resistance to dezincification; prevents zinc leaching and maintains strength | Prone to dezincification in aggressive environments, causing weakening and surface degradation |

| Mechanical Strength | Maintains mechanical strength over time under corrosive conditions | Reduced mechanical strength over time due to dezincification |

| Typical Applications | Water fittings, valves, marine hardware requiring long-term durability | General-purpose fittings and components where corrosion is less severe |

| Cost | Higher due to alloying additions and manufacturing process | Lower, widely available and cost-effective |

Introduction to Brass Alloys

Dezincification-resistant brass alloys contain a higher proportion of alloying elements such as arsenic or tin, enhancing their resistance to corrosion compared to standard brass, which primarily consists of copper and zinc. Standard brass alloys are more susceptible to dezincification, a form of selective leaching that weakens the metal and compromises its mechanical properties. These differences influence the selection of brass alloys in plumbing, marine, and industrial applications where durability and longevity against corrosive environments are critical.

What is Dezincification in Brass?

Dezincification in brass refers to the selective leaching of zinc from the alloy, causing a porous, weakened copper-rich structure. This corrosion phenomenon predominantly affects standard brass, especially in environments with water exposure or acidic conditions. Dezincification-resistant brass contains alloying elements like arsenic or antimony, which inhibit zinc loss and ensure enhanced durability and strength.

Composition of Standard Brass

Standard brass typically contains about 60-70% copper and 30-40% zinc, with small amounts of lead added to improve machinability. The higher zinc content in standard brass makes it more susceptible to dezincification, where zinc leaches out, weakening the material. This composition contrasts with dezincification-resistant brass, which includes elements like arsenic or tin to inhibit zinc loss and enhance corrosion resistance.

Dezincification-Resistant Brass: Key Features

Dezincification-resistant brass contains a higher percentage of aluminum and manganese, which significantly reduces the leaching of zinc from the alloy in corrosive environments. This type of brass exhibits enhanced durability and corrosion resistance, making it ideal for plumbing and marine applications where exposure to water and chemicals is common. Its microstructure is specifically engineered to prevent dezincification, ensuring long-term performance and structural integrity compared to standard brass.

Comparative Corrosion Resistance

Dezincification-resistant brass exhibits superior corrosion resistance compared to standard brass due to its specialized alloy composition, which significantly reduces zinc leaching in aggressive environments. This enhanced durability is particularly evident in marine and chemical applications where standard brass suffers from dezincification, leading to weakened structural integrity. The presence of additives such as arsenic or antimony in dezincification-resistant brass effectively inhibits selective zinc corrosion, prolonging component lifespan and maintaining mechanical performance.

Mechanical Properties: Strength & Durability

Dezincification-resistant brass exhibits enhanced mechanical properties, including higher tensile strength and improved durability compared to standard brass, making it ideal for demanding applications. Its alloy composition reduces zinc leaching, preserving structural integrity under stress and corrosion conditions. Standard brass, often weaker due to zinc depletion, tends to suffer from reduced mechanical performance and premature failure in aggressive environments.

Common Applications of Each Brass Type

Dezincification-resistant brass is commonly used in plumbing fixtures, valves, and marine applications where exposure to corrosive environments like seawater increases the risk of dezincification. Standard brass is widely employed in electrical connectors, musical instruments, and decorative hardware due to its good machinability and aesthetic appeal. Both brass types serve critical roles, with dezincification-resistant brass prioritized for durability in harsh conditions, while standard brass excels in general-purpose and ornamental uses.

Cost Considerations and Economic Impact

Dezincification-resistant brass typically incurs higher initial costs compared to standard brass due to specialized alloying with elements like arsenic or antimony to improve corrosion resistance. Despite the premium price, its longer lifespan and reduced maintenance expenses offer significant economic advantages for plumbing and marine applications. Standard brass may appear cost-effective upfront but often results in increased replacement and repair costs due to zinc leaching and material degradation.

Maintenance and Longevity

Dezincification-resistant brass significantly extends the lifespan of plumbing components by reducing the corrosion process that typically plagues standard brass in chlorinated water environments. This alloy's enhanced resistance to dezincification minimizes maintenance frequency and associated costs, ensuring more reliable performance over time. Standard brass, while initially cost-effective, requires frequent inspection and replacement due to its vulnerability to zinc leaching and structural degradation.

Choosing the Right Brass for Your Application

Dezincification-resistant brass (DR brass) offers superior corrosion resistance and durability compared to standard brass, making it ideal for plumbing and marine applications where exposure to water is constant. Standard brass contains a higher zinc content, which is prone to dezincification, leading to structural weaknesses in harsh environments. Selecting DR brass ensures long-term reliability and safety in systems requiring enhanced resistance to dezincification and dezincification-induced failures.

Dezincification-Resistant Brass vs Standard Brass Infographic

materialdif.com

materialdif.com