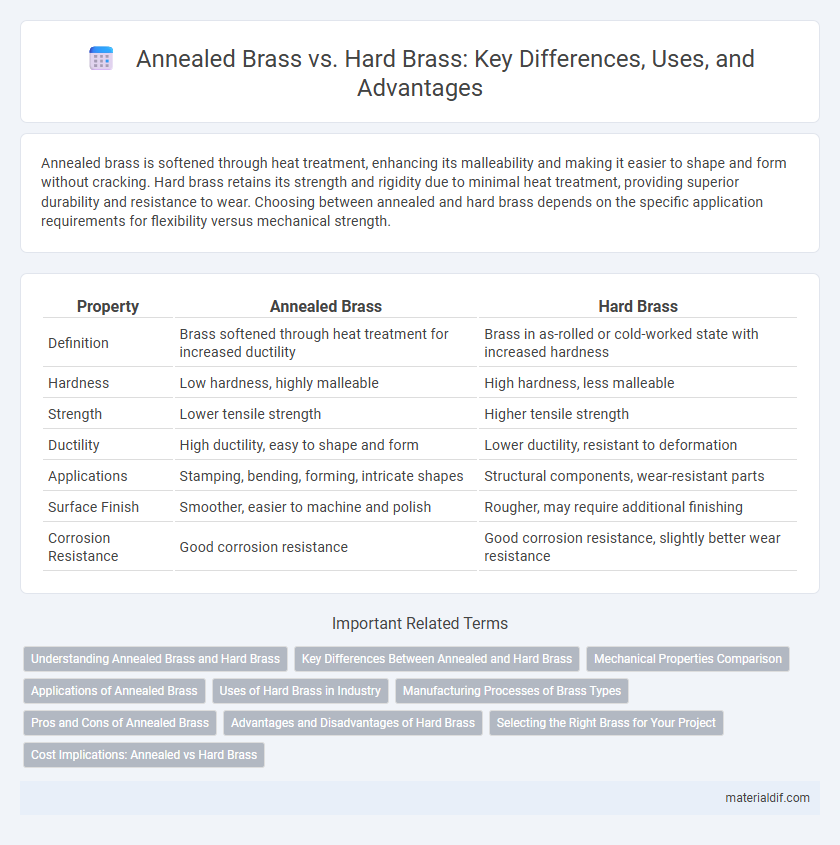

Annealed brass is softened through heat treatment, enhancing its malleability and making it easier to shape and form without cracking. Hard brass retains its strength and rigidity due to minimal heat treatment, providing superior durability and resistance to wear. Choosing between annealed and hard brass depends on the specific application requirements for flexibility versus mechanical strength.

Table of Comparison

| Property | Annealed Brass | Hard Brass |

|---|---|---|

| Definition | Brass softened through heat treatment for increased ductility | Brass in as-rolled or cold-worked state with increased hardness |

| Hardness | Low hardness, highly malleable | High hardness, less malleable |

| Strength | Lower tensile strength | Higher tensile strength |

| Ductility | High ductility, easy to shape and form | Lower ductility, resistant to deformation |

| Applications | Stamping, bending, forming, intricate shapes | Structural components, wear-resistant parts |

| Surface Finish | Smoother, easier to machine and polish | Rougher, may require additional finishing |

| Corrosion Resistance | Good corrosion resistance | Good corrosion resistance, slightly better wear resistance |

Understanding Annealed Brass and Hard Brass

Annealed brass undergoes a heat treatment process that softens the metal, enhancing its ductility and making it easier to bend or shape without cracking. Hard brass retains its natural hardness and strength due to the absence of this annealing process, making it ideal for applications requiring durability and wear resistance. Understanding the differences between annealed and hard brass is crucial for selecting the appropriate material based on flexibility needs and mechanical performance.

Key Differences Between Annealed and Hard Brass

Annealed brass is softened through a heat treatment process that increases its malleability and ductility, making it ideal for intricate forming and shaping applications. Hard brass retains its original hardness and strength, providing superior wear resistance and structural integrity in mechanical components and fittings. The primary distinction lies in annealed brass being more pliable for fabrication, whereas hard brass offers greater durability and toughness for load-bearing uses.

Mechanical Properties Comparison

Annealed brass exhibits enhanced ductility and reduced hardness, making it ideal for applications requiring extensive forming and bending. Hard brass offers significantly higher tensile strength and improved wear resistance, suitable for mechanical parts subjected to stress and friction. The annealing process alters the microstructure, decreasing yield strength while increasing elongation, contrasting with the hardened state that maintains structural integrity under load.

Applications of Annealed Brass

Annealed brass, known for its increased malleability and ductility due to heat treatment, is widely applied in manufacturing precision components such as musical instruments, electrical connectors, and decorative hardware. Its softness allows for easier machining, making it ideal for intricate designs and detailed fabrication processes. Industries requiring corrosion resistance and enhanced formability prefer annealed brass for sustainable and reliable product performance.

Uses of Hard Brass in Industry

Hard brass is widely used in industrial applications requiring high strength and durability, such as manufacturing gears, valves, and fittings for machinery. Its resistance to wear and corrosion makes it ideal for components in automotive, aerospace, and marine industries. The alloy's ability to maintain structural integrity under mechanical stress ensures reliable performance in heavy-duty environments.

Manufacturing Processes of Brass Types

Annealed brass undergoes a controlled heating and slow cooling process that softens the metal, enhancing its ductility and making it easier to shape during manufacturing. Hard brass is produced through work hardening techniques such as cold rolling or drawing, which increase its strength and hardness by deforming the metal's crystal structure without heat treatment. These manufacturing processes determine the mechanical properties and applications of brass, with annealed brass favored for intricate forming and hard brass selected for durability and wear resistance.

Pros and Cons of Annealed Brass

Annealed brass offers enhanced malleability and improved machinability, making it ideal for intricate forming and detailed fabrication processes. Its softness, however, results in lower tensile strength and reduced wear resistance compared to hard brass, limiting its use in high-stress or abrasive applications. The superior ductility of annealed brass allows for easier shaping and bending, but it may deform more easily under mechanical pressure.

Advantages and Disadvantages of Hard Brass

Hard brass offers superior strength and durability compared to annealed brass, making it ideal for applications requiring high wear resistance and structural integrity, such as in mechanical components and fittings. Its harder composition can increase machining difficulty and reduce malleability, limiting its suitability for complex shaping or forming processes. Hard brass also tends to exhibit better corrosion resistance and improved surface hardness, but it may be more prone to cracking under extreme stress or impact than softer, more ductile annealed brass.

Selecting the Right Brass for Your Project

Annealed brass offers enhanced malleability and ease of machining, making it ideal for intricate shaping and detailed work, while hard brass provides superior strength and durability suited for structural applications. Selecting the right brass depends on the project's requirements for flexibility versus mechanical resilience, with annealed types favored in precision components and hard brass preferred in fixtures subjected to wear. Consider alloy composition and heat treatment processes to ensure optimal performance and longevity in your specific use case.

Cost Implications: Annealed vs Hard Brass

Annealed brass typically costs more than hard brass due to the additional processing involved to soften the material, making it more malleable and easier to work with in applications such as intricate machining and forming. Hard brass, being less processed and harder, generally incurs lower manufacturing costs but may increase expenses in tooling wear and machining time during production. Selecting between annealed and hard brass significantly impacts overall project budgets, with annealed brass favoring flexibility and precision despite higher material costs, while hard brass offers cost-efficiency in simpler fabrication environments.

Annealed Brass vs Hard Brass Infographic

materialdif.com

materialdif.com