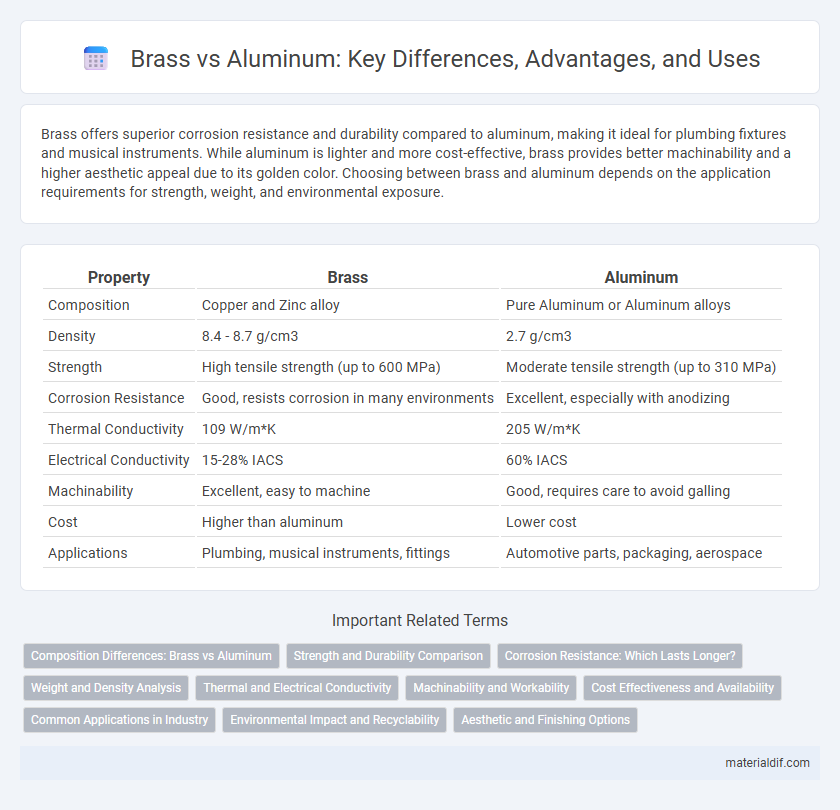

Brass offers superior corrosion resistance and durability compared to aluminum, making it ideal for plumbing fixtures and musical instruments. While aluminum is lighter and more cost-effective, brass provides better machinability and a higher aesthetic appeal due to its golden color. Choosing between brass and aluminum depends on the application requirements for strength, weight, and environmental exposure.

Table of Comparison

| Property | Brass | Aluminum |

|---|---|---|

| Composition | Copper and Zinc alloy | Pure Aluminum or Aluminum alloys |

| Density | 8.4 - 8.7 g/cm3 | 2.7 g/cm3 |

| Strength | High tensile strength (up to 600 MPa) | Moderate tensile strength (up to 310 MPa) |

| Corrosion Resistance | Good, resists corrosion in many environments | Excellent, especially with anodizing |

| Thermal Conductivity | 109 W/m*K | 205 W/m*K |

| Electrical Conductivity | 15-28% IACS | 60% IACS |

| Machinability | Excellent, easy to machine | Good, requires care to avoid galling |

| Cost | Higher than aluminum | Lower cost |

| Applications | Plumbing, musical instruments, fittings | Automotive parts, packaging, aerospace |

Composition Differences: Brass vs Aluminum

Brass is an alloy primarily composed of copper and zinc, with varying zinc content influencing its strength and corrosion resistance, while aluminum is a pure elemental metal known for its lightweight and high corrosion resistance. The copper content in brass typically ranges from 55% to 95%, giving it greater density and electrical conductivity compared to aluminum, which contains trace impurities but is predominantly aluminum metal. These compositional differences result in brass exhibiting better machinability and thermal conductivity, whereas aluminum offers superior weight-to-strength ratio and resistance to oxidation.

Strength and Durability Comparison

Brass exhibits superior strength and durability compared to aluminum, making it ideal for applications requiring resistance to wear and corrosion. Its higher tensile strength and hardness contribute to better performance under mechanical stress, especially in plumbing and musical instrument components. Aluminum, while lightweight and corrosion-resistant, lacks the robust durability of brass in demanding structural uses.

Corrosion Resistance: Which Lasts Longer?

Brass exhibits superior corrosion resistance compared to aluminum, particularly in marine and industrial environments where exposure to moisture and chemicals is frequent. Its copper content forms a protective oxide layer, preventing rust and degradation, resulting in longer-lasting durability under harsh conditions. Aluminum, while lightweight and resistant to certain types of corrosion, tends to oxidize and lose structural integrity faster when exposed to saltwater or acidic environments.

Weight and Density Analysis

Brass has a significantly higher density, approximately 8.5 g/cm3, compared to aluminum's density of around 2.7 g/cm3, resulting in brass being considerably heavier for the same volume. This high density makes brass ideal for applications requiring durability and weight, such as musical instruments and plumbing fixtures. Conversely, aluminum's low weight and density contribute to its widespread use in aerospace and automotive industries where reducing mass is critical for performance and fuel efficiency.

Thermal and Electrical Conductivity

Brass exhibits lower thermal and electrical conductivity compared to aluminum, making aluminum a superior choice for applications requiring efficient heat and electrical transfer. The thermal conductivity of aluminum typically ranges from 205 to 235 W/m*K, whereas brass averages around 109 W/m*K. In terms of electrical conductivity, aluminum measures approximately 37.8 million S/m, while brass is significantly less conductive, around 15-20 million S/m, highlighting aluminum's advantage in thermal and electrical performance.

Machinability and Workability

Brass offers superior machinability compared to aluminum, allowing for smoother cutting and finer finishes due to its lower tool wear and excellent chip formation. Its workability is enhanced by good ductility and malleability, making it easier to form and shape without cracking or fracturing under stress. Aluminum, while lightweight and corrosion-resistant, generally requires specialized tooling and slower machining speeds to avoid surface degradation and tool damage.

Cost Effectiveness and Availability

Brass generally offers superior cost-effectiveness compared to aluminum due to its durability and lower maintenance needs, making it a preferred choice in applications requiring longevity and reliability. Although aluminum is often cheaper upfront, its higher susceptibility to corrosion and wear can lead to increased replacement expenses over time. Brass also benefits from widespread availability in various alloys, ensuring consistent supply for industrial and decorative uses.

Common Applications in Industry

Brass is widely used in plumbing, electrical components, and musical instruments due to its excellent corrosion resistance and acoustic properties, whereas aluminum is preferred in aerospace, automotive, and packaging industries for its lightweight and high strength-to-weight ratio. Brass's machinability and antimicrobial qualities make it ideal for valves, fittings, and decorative hardware, while aluminum's thermal conductivity and recyclability benefit heat exchangers and transportation parts. Industry professionals select brass or aluminum based on specific application demands including durability, weight, and environmental exposure.

Environmental Impact and Recyclability

Brass, an alloy primarily composed of copper and zinc, offers superior recyclability compared to aluminum due to its higher retention of material properties after recycling, which reduces the demand for virgin resources and lowers environmental impact. Aluminum production requires significantly more energy, contributing to higher carbon emissions, whereas brass recycling consumes less energy and produces fewer greenhouse gases. The durability and corrosion resistance of brass also prolong product life cycles, further minimizing environmental footprint compared to aluminum alternatives.

Aesthetic and Finishing Options

Brass offers a rich, warm golden hue that enhances aesthetic appeal with natural luster and patina development over time, making it ideal for decorative applications. Aluminum provides a sleek, modern look with its silver-gray finish and can be anodized or powder-coated to achieve a variety of colors and textures. Brass finishes often include polishing, lacquering, and antiquing, while aluminum finishes focus on anodizing, painting, and powder coating, offering more versatility in color customization.

Brass vs Aluminum Infographic

materialdif.com

materialdif.com