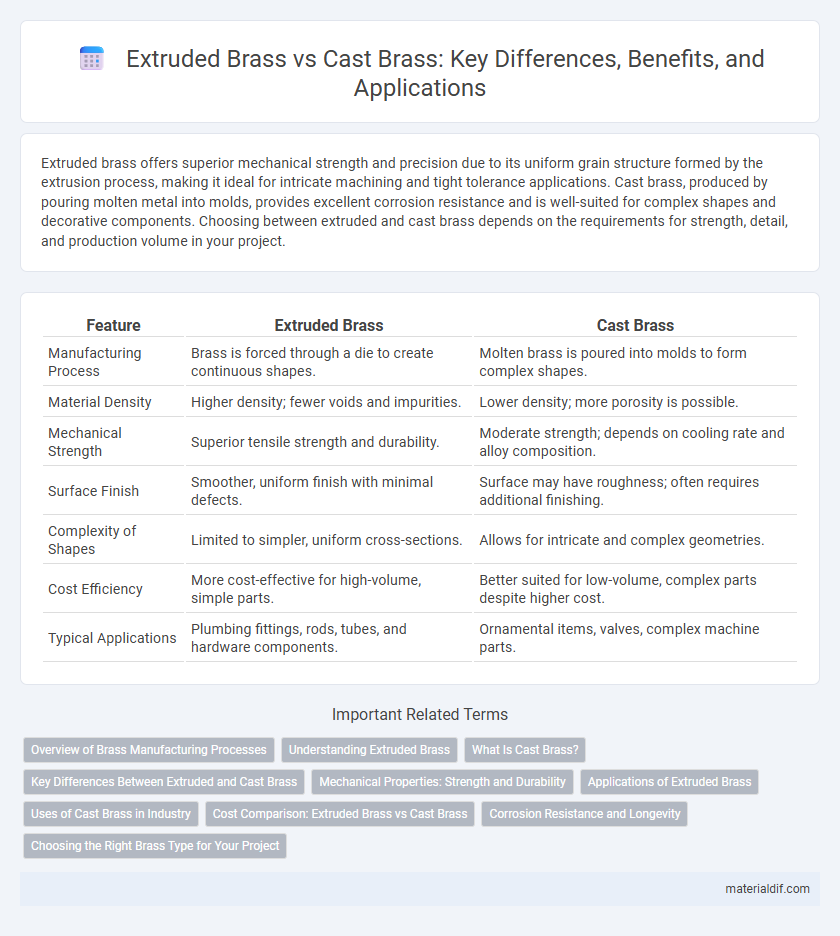

Extruded brass offers superior mechanical strength and precision due to its uniform grain structure formed by the extrusion process, making it ideal for intricate machining and tight tolerance applications. Cast brass, produced by pouring molten metal into molds, provides excellent corrosion resistance and is well-suited for complex shapes and decorative components. Choosing between extruded and cast brass depends on the requirements for strength, detail, and production volume in your project.

Table of Comparison

| Feature | Extruded Brass | Cast Brass |

|---|---|---|

| Manufacturing Process | Brass is forced through a die to create continuous shapes. | Molten brass is poured into molds to form complex shapes. |

| Material Density | Higher density; fewer voids and impurities. | Lower density; more porosity is possible. |

| Mechanical Strength | Superior tensile strength and durability. | Moderate strength; depends on cooling rate and alloy composition. |

| Surface Finish | Smoother, uniform finish with minimal defects. | Surface may have roughness; often requires additional finishing. |

| Complexity of Shapes | Limited to simpler, uniform cross-sections. | Allows for intricate and complex geometries. |

| Cost Efficiency | More cost-effective for high-volume, simple parts. | Better suited for low-volume, complex parts despite higher cost. |

| Typical Applications | Plumbing fittings, rods, tubes, and hardware components. | Ornamental items, valves, complex machine parts. |

Overview of Brass Manufacturing Processes

Extruded brass is produced by forcing heated brass billets through a die to create uniform shapes with enhanced strength and dimensional accuracy, ideal for tubing and rods. Cast brass involves pouring molten brass into molds, allowing complex and intricate designs but often with less mechanical strength and potential porosity. These manufacturing differences impact the material's applications, cost, and performance in industries like plumbing, automotive, and decorative hardware.

Understanding Extruded Brass

Extruded brass offers superior mechanical properties, including increased tensile strength and enhanced durability, due to the continuous shaping process that aligns its grain structure. This manufacturing method results in consistent dimensions and improved surface finish, making extruded brass ideal for precision components in plumbing, automotive, and electrical applications. Understanding extruded brass involves recognizing its advantages over cast brass, particularly in high-stress environments where reliability and material integrity are critical.

What Is Cast Brass?

Cast brass is a metal alloy formed by melting brass and pouring it into molds to solidify, creating intricate shapes with excellent detail and complex geometries. This manufacturing process allows for greater design flexibility compared to extrusion, making cast brass ideal for components requiring detailed features such as decorative hardware and plumbing fittings. Cast brass typically exhibits slightly different mechanical properties, including enhanced strength and durability due to controlled cooling and solidification.

Key Differences Between Extruded and Cast Brass

Extruded brass is created by forcing heated brass through a die, resulting in uniform grain structure and superior mechanical properties, making it ideal for applications requiring enhanced strength and precision, such as architectural components and industrial fittings. Cast brass, formed by pouring molten brass into molds, often exhibits a coarser grain structure and increased porosity, which can lead to reduced strength but allows for more complex shapes and detailed designs suited for decorative items and intricate hardware. The key differences lie in their manufacturing processes, mechanical performance, and suitability for specific uses, with extruded brass favored for durability and dimensional accuracy, while cast brass excels in versatility and intricate craftsmanship.

Mechanical Properties: Strength and Durability

Extruded brass exhibits superior mechanical properties compared to cast brass, with higher tensile strength and improved ductility due to its refined grain structure achieved through the extrusion process. Cast brass generally has lower strength and durability because of its coarse grains and potential porosity formed during solidification. These characteristics make extruded brass more suitable for applications requiring enhanced load-bearing capacity and resistance to mechanical stress.

Applications of Extruded Brass

Extruded brass is widely used in applications requiring precise shapes and tight tolerances, such as electrical connectors, plumbing fixtures, and mechanical components. Its uniform grain structure enhances machinability and strength, making it ideal for parts subjected to high stress or complex machining processes. Industries like automotive, aerospace, and electronics rely on extruded brass for reliable, high-performance components.

Uses of Cast Brass in Industry

Cast brass is widely used in industries requiring complex shapes and high corrosion resistance, such as automotive manufacturing for engine components and plumbing fixtures. Its ability to be cast into intricate molds makes it ideal for producing valves, fittings, and decorative hardware. The industrial applications capitalize on cast brass's durability and machinability for both functional and aesthetic purposes.

Cost Comparison: Extruded Brass vs Cast Brass

Extruded brass typically incurs higher production costs due to the energy-intensive process and precise machinery required, resulting in increased material and fabrication expenses compared to cast brass. Cast brass offers a more cost-effective solution for complex shapes and large quantities, benefiting from lower tooling and molding costs in mass production. Businesses often choose cast brass to reduce overall expenses without compromising structural integrity for specific applications.

Corrosion Resistance and Longevity

Extruded brass exhibits superior corrosion resistance due to its uniform grain structure and fewer internal defects compared to cast brass, which often contains porosity that can accelerate corrosion. The enhanced durability of extruded brass ensures longer service life in demanding environments, making it ideal for plumbing and marine applications. Cast brass, while cost-effective for complex shapes, generally shows reduced longevity and greater susceptibility to environmental degradation.

Choosing the Right Brass Type for Your Project

Extruded brass offers superior strength, uniformity, and surface finish, making it ideal for precision machining and structural applications requiring consistent mechanical properties. Cast brass provides enhanced complex shapes and design flexibility, suitable for decorative or intricate components where aesthetic detail is prioritized over mechanical uniformity. Selecting between extruded and cast brass depends on the project's requirements for durability, dimensional tolerance, and design complexity.

Extruded Brass vs Cast Brass Infographic

materialdif.com

materialdif.com