Brass sheets are thinner, typically less than 6mm, offering flexibility for detailed work and easy shaping, while brass plates are thicker, providing greater strength and durability for structural applications. The choice between brass sheet and brass plate depends on the specific requirements of thickness, rigidity, and the intended use in manufacturing or construction. Brass sheets are ideal for decorative elements and light-duty projects, whereas brass plates support heavy-duty tasks such as industrial machinery components.

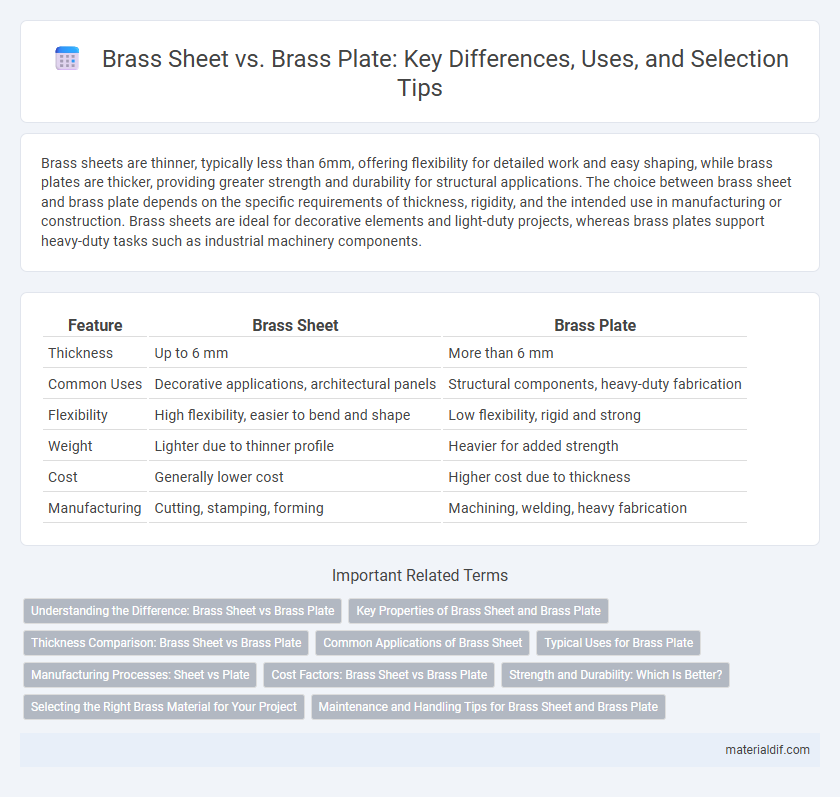

Table of Comparison

| Feature | Brass Sheet | Brass Plate |

|---|---|---|

| Thickness | Up to 6 mm | More than 6 mm |

| Common Uses | Decorative applications, architectural panels | Structural components, heavy-duty fabrication |

| Flexibility | High flexibility, easier to bend and shape | Low flexibility, rigid and strong |

| Weight | Lighter due to thinner profile | Heavier for added strength |

| Cost | Generally lower cost | Higher cost due to thickness |

| Manufacturing | Cutting, stamping, forming | Machining, welding, heavy fabrication |

Understanding the Difference: Brass Sheet vs Brass Plate

Brass sheets typically measure less than 6mm in thickness, offering flexibility and ease of fabrication for applications like decorative panels, roofing, and musical instruments. Brass plates are thicker, usually exceeding 6mm, providing enhanced strength and durability suitable for structural components, heavy-duty industrial parts, and machining. The primary difference lies in thickness, which influences their mechanical properties, cost, and optimal use cases across manufacturing and construction industries.

Key Properties of Brass Sheet and Brass Plate

Brass sheets typically have a thinner gauge, ranging from 0.2mm to 6mm, providing flexibility and ease of fabrication for applications like decorative elements and detailed metalworking. Brass plates, thicker at over 6mm, offer superior strength and durability, making them ideal for heavy-duty industrial components and structural uses. Both brass sheets and plates share key properties such as excellent corrosion resistance, high malleability, and good thermal conductivity, but their thickness directly impacts their mechanical performance and suitability for specific projects.

Thickness Comparison: Brass Sheet vs Brass Plate

Brass sheets typically range from 0.2 mm to 6 mm in thickness, making them ideal for applications requiring flexibility and ease of fabrication. Brass plates are thicker, usually starting from 6 mm and can exceed several inches, providing greater strength and durability for structural purposes. When comparing thickness, brass sheets offer lightweight versatility, whereas brass plates deliver robust performance in heavy-duty environments.

Common Applications of Brass Sheet

Brass sheets are commonly used in decorative applications, musical instruments, and architectural elements due to their excellent malleability and corrosion resistance. They are ideal for crafting intricate designs, signage, and panels where thinner material is beneficial. In contrast, brass plates, which are thicker, are preferred for heavy-duty applications like machinery components and structural supports.

Typical Uses for Brass Plate

Brass plate is typically used in applications requiring greater thickness and strength compared to brass sheet, such as heavy-duty construction, industrial machinery components, and structural support elements. Its enhanced durability makes it suitable for manufacturing flanges, heavy-duty electrical components, and marine hardware. Brass plate's corrosion resistance and machinability also allow for precise engineering parts in automotive and aerospace industries.

Manufacturing Processes: Sheet vs Plate

Brass sheet is produced by rolling brass slabs into thin, uniform thicknesses typically under 6mm, allowing for high precision and surface finish suitable for applications like decorative panels and electrical components. Brass plate, thicker than sheets and usually exceeding 6mm, undergoes hot rolling or casting followed by machining, resulting in increased structural strength for heavy-duty applications such as industrial machinery and architectural supports. Manufacturing brass sheets focuses on tight dimensional control through cold rolling, whereas brass plates prioritize mechanical properties and durability through controlled hot rolling and heat treatment processes.

Cost Factors: Brass Sheet vs Brass Plate

Brass sheet typically costs less than brass plate due to its thinner gauge and lower material volume, making it more economical for applications requiring lightweight components. Brass plate, being thicker and heavier, involves higher raw material costs and increased manufacturing expenses, including longer processing times and more energy consumption. The choice between brass sheet and plate hinges on balancing cost factors with mechanical strength, durability, and specific project requirements.

Strength and Durability: Which Is Better?

Brass plates generally offer greater strength and durability compared to brass sheets due to their increased thickness, making them suitable for heavy-duty applications requiring enhanced structural support. The thickness of brass plates improves resistance to wear, deformation, and impact, while brass sheets, being thinner, provide more flexibility but less mechanical strength. For projects prioritizing long-term robustness and load-bearing capacity, brass plates are the superior choice over brass sheets.

Selecting the Right Brass Material for Your Project

Brass sheets are thinner, typically less than 6mm, offering flexibility and ease of shaping for applications like decorative panels or intricate metalwork, while brass plates exceed this thickness, providing superior strength and durability suited for structural components and heavy-duty machinery parts. Selecting the right brass material depends on project requirements such as thickness, mechanical strength, and machinability; brass sheets excel in lightweight, detailed projects, whereas brass plates are ideal for load-bearing or high-wear environments. Consider factors such as corrosion resistance, thermal conductivity, and finish quality when choosing between brass sheet and brass plate to ensure optimal performance and longevity in your application.

Maintenance and Handling Tips for Brass Sheet and Brass Plate

Brass sheets require careful handling to avoid scratches due to their thinner profile, making soft gloves and clean surfaces essential during maintenance. Brass plates, being thicker and more robust, tolerate more aggressive cleaning tools but still benefit from regular polishing to prevent tarnishing and corrosion. Both brass sheets and plates should be stored in dry environments to minimize oxidation and maintain their metallic luster over time.

Brass Sheet vs Brass Plate Infographic

materialdif.com

materialdif.com