Seamless brass tubing offers superior strength and corrosion resistance due to its uniform structure, making it ideal for high-pressure applications. Welded brass tubing, while more cost-effective, may contain weak points along the weld seam that can be vulnerable to stress and corrosion. Choosing between seamless and welded brass tubing depends on the specific requirements for durability, pressure tolerance, and budget in your project.

Table of Comparison

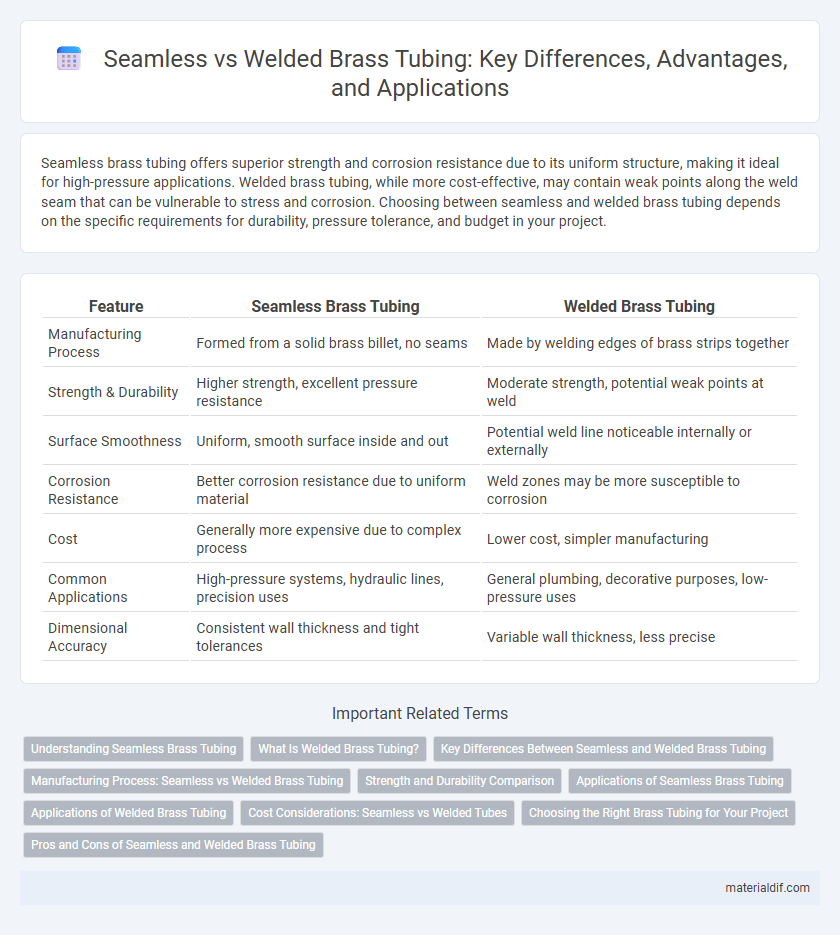

| Feature | Seamless Brass Tubing | Welded Brass Tubing |

|---|---|---|

| Manufacturing Process | Formed from a solid brass billet, no seams | Made by welding edges of brass strips together |

| Strength & Durability | Higher strength, excellent pressure resistance | Moderate strength, potential weak points at weld |

| Surface Smoothness | Uniform, smooth surface inside and out | Potential weld line noticeable internally or externally |

| Corrosion Resistance | Better corrosion resistance due to uniform material | Weld zones may be more susceptible to corrosion |

| Cost | Generally more expensive due to complex process | Lower cost, simpler manufacturing |

| Common Applications | High-pressure systems, hydraulic lines, precision uses | General plumbing, decorative purposes, low-pressure uses |

| Dimensional Accuracy | Consistent wall thickness and tight tolerances | Variable wall thickness, less precise |

Understanding Seamless Brass Tubing

Seamless brass tubing is manufactured without any joints or welds, resulting in a continuous, uniform structure that offers superior strength and corrosion resistance compared to welded alternatives. Its production involves extrusion or rotary piercing processes that create a tube from a solid brass billet, ensuring consistent wall thickness and enhanced mechanical properties. This makes seamless brass tubing ideal for high-pressure applications and situations requiring exceptional durability and reliability.

What Is Welded Brass Tubing?

Welded brass tubing is manufactured by rolling metal strips into a cylindrical shape and joining the edges through welding, creating a continuous seam along the tube. This process offers cost-effective production and versatile shapes but may result in slightly lower strength and corrosion resistance compared to seamless brass tubing. Welded brass tubing is commonly used in applications where high pressure is not a critical factor, such as decorative elements and low-pressure fluid transport.

Key Differences Between Seamless and Welded Brass Tubing

Seamless brass tubing is manufactured by extrusion, providing uniform strength and corrosion resistance throughout the material, making it ideal for high-pressure applications. Welded brass tubing is created by rolling brass sheets and welding the seam, which can introduce potential weak points but allows for more flexible shapes and cost-effective production. The key differences lie in structural integrity, production methods, and performance under stress, with seamless tubing offering superior reliability in demanding environments.

Manufacturing Process: Seamless vs Welded Brass Tubing

Seamless brass tubing is manufactured through a extrusion or rotary piercing process that creates a tube without any joints, ensuring uniformity and enhanced structural integrity. Welded brass tubing is produced by shaping a flat brass strip into a tube and joining the edges with high-frequency welding, which may result in a seam that can affect pressure resistance. The seamless process offers superior durability and is preferred for high-pressure applications, while welded tubing provides cost efficiency and versatility for less demanding uses.

Strength and Durability Comparison

Seamless brass tubing offers superior strength and durability due to its uniform structure without weld joints, reducing the risk of leaks and structural weaknesses under high pressure. Welded brass tubing, though more cost-effective, contains welded seams that can be potential failure points under stress or corrosion, compromising long-term durability. For applications requiring high-pressure resistance and longevity, seamless brass tubing is the preferred choice due to its robust integrity and enhanced performance.

Applications of Seamless Brass Tubing

Seamless brass tubing is ideal for high-pressure applications such as hydraulic systems, refrigeration, and fuel lines due to its superior strength and resistance to corrosion. Its uniform structure ensures leak-free performance in plumbing, instrumentation, and automotive industries. This type of tubing is preferred in aerospace and marine environments where durability and reliability are critical.

Applications of Welded Brass Tubing

Welded brass tubing is commonly used in applications requiring cost-effective solutions where high-pressure resistance is less critical, such as decorative fixtures, HVAC systems, and plumbing. Its manufacturing process allows for precise dimensions and consistent wall thickness, making it ideal for architectural elements and fluid transfer lines with moderate stress. Industries leveraging welded brass tubing benefit from its machinability and corrosion resistance in environments like refrigeration and automotive fuel lines.

Cost Considerations: Seamless vs Welded Tubes

Seamless brass tubing generally incurs higher production costs due to the complex manufacturing process involving extrusion or rotary piercing, resulting in superior strength and durability. Welded brass tubing offers a more cost-effective solution, as it is produced by rolling and welding strips, reducing material waste and production time. Cost considerations must balance the seamless tube's higher price against the welded tubing's potential for slightly reduced mechanical properties in non-critical applications.

Choosing the Right Brass Tubing for Your Project

Seamless brass tubing offers superior strength and corrosion resistance ideal for high-pressure applications and intricate designs, while welded brass tubing provides cost-effective options for less demanding projects with moderate structural needs. Evaluate project requirements such as pressure tolerance, durability, and budget constraints to determine the appropriate type. Selecting the right brass tubing enhances performance, longevity, and overall project success.

Pros and Cons of Seamless and Welded Brass Tubing

Seamless brass tubing offers superior strength and corrosion resistance due to its uniform structure, making it ideal for high-pressure applications, but it is typically more expensive and limited in size options. Welded brass tubing provides cost-effective manufacturing with a broad range of sizes and easier customization, although the weld seam can be a potential point of weakness and corrosion. Choosing between seamless and welded brass tubing depends on balancing durability requirements and budget constraints for specific industrial uses.

Seamless Brass Tubing vs Welded Brass Tubing Infographic

materialdif.com

materialdif.com