Machinable brass offers superior precision and ease of shaping, making it ideal for intricate components requiring tight tolerances. Forging brass provides enhanced strength and durability through the forging process, resulting in parts better suited for high-stress applications. Choosing between machinable and forging brass depends on the specific mechanical requirements and manufacturing complexity of the project.

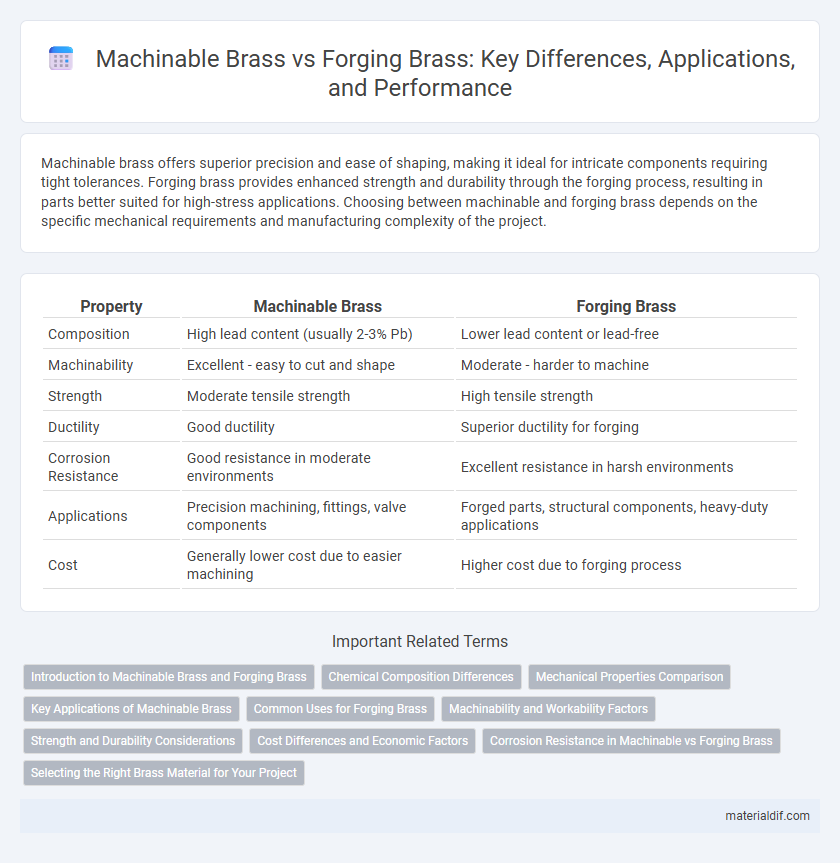

Table of Comparison

| Property | Machinable Brass | Forging Brass |

|---|---|---|

| Composition | High lead content (usually 2-3% Pb) | Lower lead content or lead-free |

| Machinability | Excellent - easy to cut and shape | Moderate - harder to machine |

| Strength | Moderate tensile strength | High tensile strength |

| Ductility | Good ductility | Superior ductility for forging |

| Corrosion Resistance | Good resistance in moderate environments | Excellent resistance in harsh environments |

| Applications | Precision machining, fittings, valve components | Forged parts, structural components, heavy-duty applications |

| Cost | Generally lower cost due to easier machining | Higher cost due to forging process |

Introduction to Machinable Brass and Forging Brass

Machinable brass is a copper-zinc alloy designed for precision machining, offering excellent dimensional stability, high tensile strength, and superior machinability for complex components. Forging brass, on the other hand, undergoes a hot or cold forging process to enhance its mechanical properties, resulting in improved hardness, durability, and resistance to wear. Both types serve distinct industrial purposes, with machinable brass preferred for intricate parts and forging brass favored for high-strength applications.

Chemical Composition Differences

Machinable brass typically contains higher levels of lead, around 2-3%, to enhance its machinability, whereas forging brass has minimal or no lead content, emphasizing strength and ductility. The copper content in machinable brass usually ranges between 61-64%, with zinc making up the balance, while forging brass often has a more balanced copper-to-zinc ratio, around 60-40%, to optimize forging properties. These chemical composition differences directly influence the mechanical behavior and applications of each brass type.

Mechanical Properties Comparison

Machinable brass typically offers higher machinability with tensile strength around 500-600 MPa and hardness up to 120 HB, making it ideal for precision components requiring complex shapes. Forging brass, on the other hand, exhibits superior mechanical properties such as greater yield strength (600-750 MPa) and improved ductility due to grain refinement from the forging process, which enhances fatigue resistance. Both materials vary significantly in microstructure and mechanical performance, influencing their suitability for different industrial applications.

Key Applications of Machinable Brass

Machinable brass is widely used in precision components such as gears, valves, and fittings due to its excellent machinability and dimensional stability. Its applications extend to electrical connectors and instrumentation parts where tight tolerances are critical. The alloy's high strength and corrosion resistance make it ideal for aerospace, automotive, and marine hardware requiring intricate shapes and smooth finishes.

Common Uses for Forging Brass

Forging brass is commonly used in applications requiring high strength and durability, such as in automotive components, heavy-duty fittings, and industrial machinery parts. Its excellent machinability combined with superior mechanical properties makes it ideal for manufacturing valves, fasteners, and gears. The material's resistance to wear and corrosion also supports its widespread use in plumbing and electrical connectors.

Machinability and Workability Factors

Machinable brass offers superior machinability due to its finely tuned alloy composition, allowing for precise cutting, drilling, and shaping with minimal tool wear. Forging brass, while strong and durable, presents lower workability because it requires higher force and specialized equipment for shaping, making it less suitable for intricate machining processes. The choice between machinable and forging brass depends largely on the complexity of the desired components and production efficiency requirements.

Strength and Durability Considerations

Machinable brass typically offers superior dimensional accuracy and ease of fabrication, making it ideal for precision components, but it generally exhibits lower strength compared to forging brass. Forging brass undergoes a plastic deformation process that enhances its grain structure, resulting in greater tensile strength and improved durability under high-stress conditions. Selecting between machinable and forging brass depends on the specific application requirements, with forging brass preferred for heavy-duty, impact-resistant parts and machinable brass suited for detailed, low-load applications.

Cost Differences and Economic Factors

Machinable brass typically incurs higher initial costs due to precise manufacturing processes and tight tolerances, yet it reduces long-term expenses through improved machinability and lower tool wear. Forging brass often has a lower upfront price, benefiting from mass production economies, but may lead to increased machining time and material waste. Evaluating cost differences requires balancing material price against machining efficiency and production volume to optimize overall economic factors.

Corrosion Resistance in Machinable vs Forging Brass

Machinable brass exhibits superior corrosion resistance compared to forging brass due to its higher zinc content and controlled alloy composition, which enhances its ability to withstand oxidizing environments. Forging brass, typically used for structural applications, may have lower corrosion resistance because of its denser grain structure and less refined alloy elements. This difference makes machinable brass more suitable for marine and plumbing applications where exposure to moisture and corrosive substances is frequent.

Selecting the Right Brass Material for Your Project

Machinable brass offers excellent precision and ease of cutting, making it ideal for complex components requiring tight tolerances. Forging brass provides superior strength and durability, suited for high-stress applications and structural parts. Selecting the right brass material depends on balancing machinability and mechanical properties based on the specific requirements of your project.

Machinable Brass vs Forging Brass Infographic

materialdif.com

materialdif.com