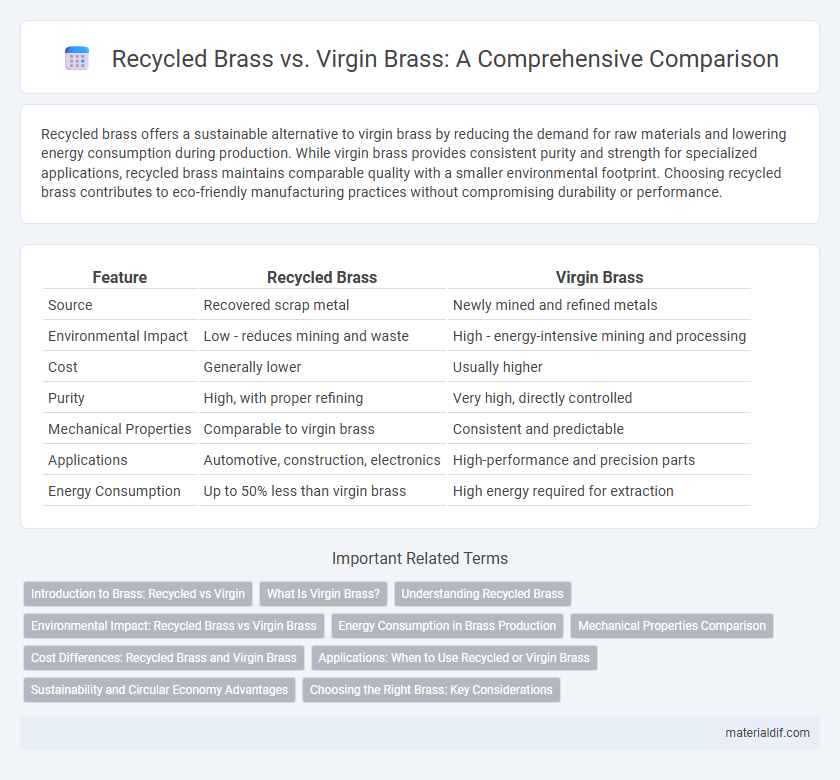

Recycled brass offers a sustainable alternative to virgin brass by reducing the demand for raw materials and lowering energy consumption during production. While virgin brass provides consistent purity and strength for specialized applications, recycled brass maintains comparable quality with a smaller environmental footprint. Choosing recycled brass contributes to eco-friendly manufacturing practices without compromising durability or performance.

Table of Comparison

| Feature | Recycled Brass | Virgin Brass |

|---|---|---|

| Source | Recovered scrap metal | Newly mined and refined metals |

| Environmental Impact | Low - reduces mining and waste | High - energy-intensive mining and processing |

| Cost | Generally lower | Usually higher |

| Purity | High, with proper refining | Very high, directly controlled |

| Mechanical Properties | Comparable to virgin brass | Consistent and predictable |

| Applications | Automotive, construction, electronics | High-performance and precision parts |

| Energy Consumption | Up to 50% less than virgin brass | High energy required for extraction |

Introduction to Brass: Recycled vs Virgin

Recycled brass is produced by melting down scrap brass materials, preserving the metal's properties while reducing environmental impact and energy consumption compared to virgin brass. Virgin brass, made from newly mined copper and zinc, offers consistent purity and mechanical strength essential for high-precision applications. Choosing between recycled and virgin brass depends on factors like quality requirements, sustainability goals, and cost efficiency in manufacturing processes.

What Is Virgin Brass?

Virgin brass is an alloy composed primarily of copper and zinc, produced directly from raw, unprocessed metals without the use of previously recycled materials. This type of brass offers consistent quality, superior strength, and enhanced corrosion resistance compared to recycled counterparts. Industries such as electronics and precision manufacturing often prefer virgin brass to ensure optimal performance and reliability in their components.

Understanding Recycled Brass

Recycled brass is produced by melting down scrap brass materials, reducing the need for new raw metal extraction and conserving natural resources. This process not only lowers energy consumption by up to 50% compared to producing virgin brass but also decreases environmental pollution and landfill waste. Recycled brass maintains comparable durability and corrosion resistance, making it a sustainable and efficient choice for manufacturing applications.

Environmental Impact: Recycled Brass vs Virgin Brass

Recycled brass significantly reduces environmental impact by lowering energy consumption and minimizing raw material extraction compared to virgin brass, which demands intensive mining and processing of copper and zinc ores. The production of recycled brass emits fewer greenhouse gases, contributing to decreased carbon footprint and reduced ecological disruption. Utilizing recycled brass supports sustainable manufacturing practices by conserving natural resources and promoting circular economy principles in the metal industry.

Energy Consumption in Brass Production

Recycled brass significantly reduces energy consumption compared to virgin brass production, saving up to 60-70% of the energy required for melting and refining. Virgin brass production involves extracting and processing raw ores, which demands large quantities of fossil fuels and electricity, contributing to higher carbon emissions. Utilizing recycled brass not only lowers energy use but also minimizes environmental impacts associated with mining and smelting.

Mechanical Properties Comparison

Recycled brass maintains mechanical properties comparable to virgin brass, including tensile strength, hardness, and ductility, making it a viable alternative in manufacturing. The alloy composition remains consistent through efficient recycling processes, ensuring reliable performance in applications such as plumbing, electrical components, and automotive parts. Utilizing recycled brass contributes to sustainability without compromising material strength or durability.

Cost Differences: Recycled Brass and Virgin Brass

Recycled brass typically costs 20-30% less than virgin brass due to lower raw material expenses and reduced energy consumption during production. Virgin brass involves higher costs as it requires mining, refining, and processing of raw ores, which increases overall manufacturing expenses. The cost efficiency of recycled brass makes it a preferred choice for industries aiming to reduce material costs without compromising alloy quality.

Applications: When to Use Recycled or Virgin Brass

Recycled brass is ideal for applications requiring cost-effectiveness and environmental sustainability, such as in construction hardware, plumbing fittings, and decorative items. Virgin brass is preferred in high-precision components like aerospace parts, electrical connectors, and musical instruments where material purity and consistent mechanical properties are critical. Selecting between recycled and virgin brass depends on application-specific requirements for strength, corrosion resistance, and manufacturing tolerances.

Sustainability and Circular Economy Advantages

Recycled brass significantly reduces the demand for virgin metal, lowering mining activities and minimizing environmental degradation. Its reuse in manufacturing supports circular economy principles by conserving resources and reducing energy consumption by up to 50% compared to producing virgin brass. This efficient material lifecycle helps decrease carbon emissions and promotes sustainable production practices in various industries.

Choosing the Right Brass: Key Considerations

Selecting the right brass involves evaluating the environmental impact and performance requirements; recycled brass offers substantial eco-friendly benefits by reducing mining waste and conserving energy, while virgin brass ensures consistent purity and mechanical properties for critical applications. Consider factors such as corrosion resistance, conductivity, and tensile strength relative to the intended use, as recycled brass may vary slightly in composition. Cost-effectiveness and availability also influence the choice, with recycled brass often providing budget advantages without significant compromises in quality.

Recycled Brass vs Virgin Brass Infographic

materialdif.com

materialdif.com