Forging brass involves shaping the metal through high pressure and heat, resulting in a dense, strong material with superior mechanical properties and enhanced grain structure. Extrusion brass pushes the metal through a die, creating uniform cross-sectional profiles ideal for consistent shapes but potentially less robust than forged counterparts. Choosing between forging and extrusion depends on the application's strength requirements and design complexity.

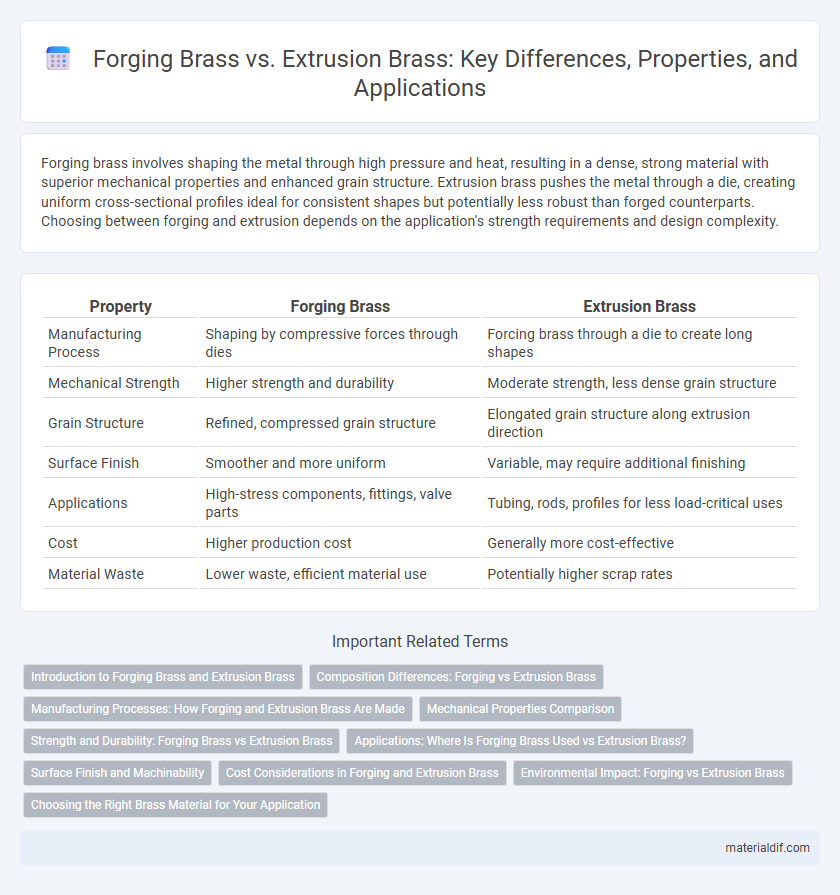

Table of Comparison

| Property | Forging Brass | Extrusion Brass |

|---|---|---|

| Manufacturing Process | Shaping by compressive forces through dies | Forcing brass through a die to create long shapes |

| Mechanical Strength | Higher strength and durability | Moderate strength, less dense grain structure |

| Grain Structure | Refined, compressed grain structure | Elongated grain structure along extrusion direction |

| Surface Finish | Smoother and more uniform | Variable, may require additional finishing |

| Applications | High-stress components, fittings, valve parts | Tubing, rods, profiles for less load-critical uses |

| Cost | Higher production cost | Generally more cost-effective |

| Material Waste | Lower waste, efficient material use | Potentially higher scrap rates |

Introduction to Forging Brass and Extrusion Brass

Forging brass involves shaping the metal using compressive forces, typically with a hammer or press, resulting in a dense, high-strength material ideal for high-stress applications. Extrusion brass is produced by forcing heated brass billet through a shaped die, enabling the creation of complex cross-sectional profiles with uniform mechanical properties. Each method impacts grain structure and mechanical characteristics, influencing final product performance in plumbing, automotive, and electrical components.

Composition Differences: Forging vs Extrusion Brass

Forging brass typically involves a higher copper content combined with zinc and limited alloying elements to enhance malleability and strength, resulting in a denser, more uniform grain structure. Extrusion brass, by contrast, often contains additional elements such as lead or tin to improve machinability, with a composition adjusted to facilitate flow during the extrusion process. These compositional differences directly influence mechanical properties, corrosion resistance, and suitability for specific industrial applications.

Manufacturing Processes: How Forging and Extrusion Brass Are Made

Forging brass involves shaping the metal by applying compressive forces, which refines the grain structure and enhances mechanical properties, making it ideal for high-strength applications. Extrusion brass is produced by forcing the heated brass billet through a die to create continuous, uniform cross-sectional profiles, enabling complex shapes and consistent dimensions. Both processes require precise temperature control and material handling to ensure optimal surface quality and structural integrity.

Mechanical Properties Comparison

Forging brass typically results in enhanced mechanical properties such as increased tensile strength, improved hardness, and better fatigue resistance due to the refined grain structure achieved through plastic deformation. Extrusion brass, while offering good dimensional accuracy and surface finish, generally exhibits lower mechanical strength and ductility compared to forged brass because the metal undergoes less severe deformation. Selecting between forging and extrusion processes depends on the required mechanical performance, with forging preferred for high-strength applications and extrusion suited for complex shapes with moderate mechanical demands.

Strength and Durability: Forging Brass vs Extrusion Brass

Forging brass enhances its strength and durability through grain refinement and work hardening, resulting in superior mechanical properties compared to extrusion brass. Extrusion brass offers consistent shapes but may exhibit lower tensile strength and fatigue resistance due to less effective grain alignment. Consequently, forged brass is preferred for applications requiring higher load-bearing capacity and long-term wear resistance.

Applications: Where Is Forging Brass Used vs Extrusion Brass?

Forging brass is commonly used in applications requiring high strength and durability, such as manufacturing heavy-duty valves, fittings, and gears for the automotive and plumbing industries. Extrusion brass is favored in producing complex, consistent profiles like tubing, rods, and intricate shapes used in architectural hardware, electrical connectors, and musical instruments. The choice between forging and extrusion depends on the application's mechanical demands and the required precision of the brass components.

Surface Finish and Machinability

Forging brass produces a denser and more refined grain structure, resulting in a superior surface finish with fewer imperfections compared to extrusion brass, which may exhibit surface roughness due to die marks. The enhanced grain uniformity in forged brass also improves machinability, allowing for smoother cutting and reduced tool wear. In contrast, extrusion brass often requires additional finishing processes to achieve comparable surface quality and can present challenges during machining due to variable material hardness.

Cost Considerations in Forging and Extrusion Brass

Forging brass generally involves higher tooling and labor costs due to complex die design and multiple forming stages, but it yields superior mechanical properties and structural integrity, making it cost-effective for high-strength applications. Extrusion brass offers lower initial setup expenses and faster production rates, reducing per-unit costs for large-volume runs with simpler shapes. Choosing between forging and extrusion depends on balancing upfront investment against long-term performance requirements and production scale, with forging favored for durability and extrusion preferred for cost-efficient mass manufacturing.

Environmental Impact: Forging vs Extrusion Brass

Forging brass typically consumes more energy due to higher temperature requirements and longer processing times, leading to a larger carbon footprint compared to extrusion. Extrusion brass often produces less waste material and allows for more efficient recycling, reducing environmental impact significantly. Lifecycle assessments reveal that extrusion processes tend to be more sustainable by minimizing emissions and conserving raw materials.

Choosing the Right Brass Material for Your Application

Forging brass offers superior strength and durability due to its refined grain structure, making it ideal for high-stress applications such as valves and fittings. Extrusion brass provides excellent dimensional accuracy and surface finish, which is beneficial for complex shapes and precision components like electrical connectors. Selecting the right brass material depends on the specific mechanical requirements and production tolerances of your application to optimize performance and longevity.

Forging Brass vs Extrusion Brass Infographic

materialdif.com

materialdif.com