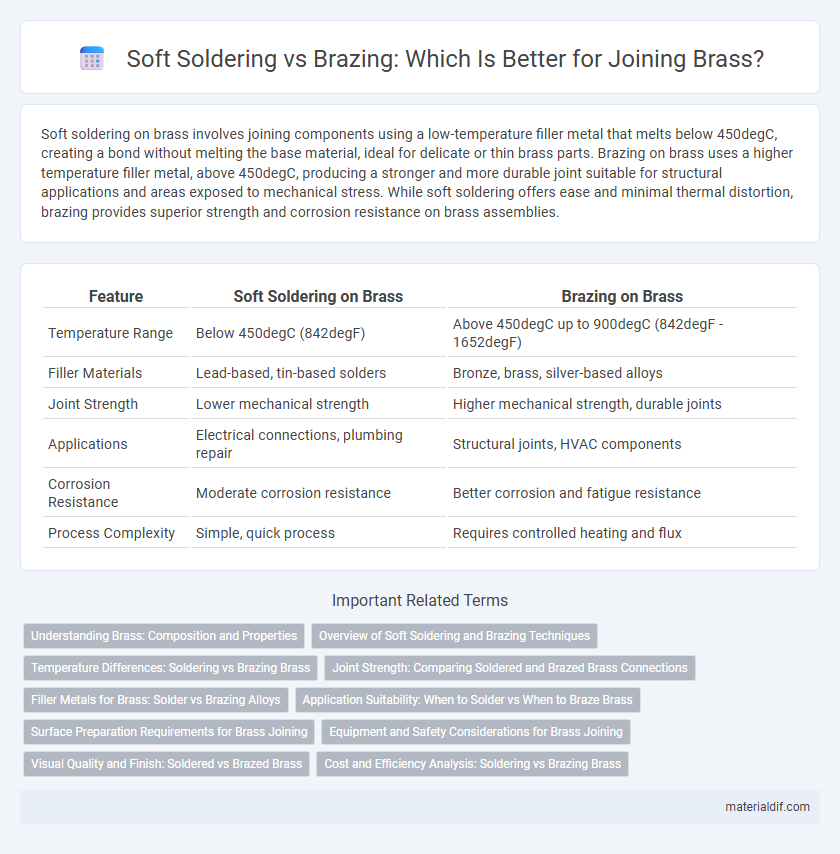

Soft soldering on brass involves joining components using a low-temperature filler metal that melts below 450degC, creating a bond without melting the base material, ideal for delicate or thin brass parts. Brazing on brass uses a higher temperature filler metal, above 450degC, producing a stronger and more durable joint suitable for structural applications and areas exposed to mechanical stress. While soft soldering offers ease and minimal thermal distortion, brazing provides superior strength and corrosion resistance on brass assemblies.

Table of Comparison

| Feature | Soft Soldering on Brass | Brazing on Brass |

|---|---|---|

| Temperature Range | Below 450degC (842degF) | Above 450degC up to 900degC (842degF - 1652degF) |

| Filler Materials | Lead-based, tin-based solders | Bronze, brass, silver-based alloys |

| Joint Strength | Lower mechanical strength | Higher mechanical strength, durable joints |

| Applications | Electrical connections, plumbing repair | Structural joints, HVAC components |

| Corrosion Resistance | Moderate corrosion resistance | Better corrosion and fatigue resistance |

| Process Complexity | Simple, quick process | Requires controlled heating and flux |

Understanding Brass: Composition and Properties

Brass, an alloy primarily composed of copper and zinc, exhibits excellent thermal conductivity and corrosion resistance, making it ideal for both soft soldering and brazing. Soft soldering, involving lower temperatures below 450degC, preserves the alloy's mechanical properties, while brazing requires temperatures above 450degC to create strong metallurgical bonds without melting the base metal. Understanding the specific zinc content and grain structure of brass is crucial, as these factors influence the alloy's response to heat and solder materials, optimizing joint strength and durability.

Overview of Soft Soldering and Brazing Techniques

Soft soldering on brass involves joining metal pieces using a filler metal with a melting point below 450degC, typically employing tin-lead or tin-silver alloys, which flow into the joint by capillary action without melting the base brass material. Brazing on brass requires heating the joint above 450degC, using filler metals like silver or copper alloys to create strong, high-temperature resistant bonds that fuse with the base metal for enhanced mechanical strength. Both techniques rely on proper surface preparation and flux application to prevent oxidation and ensure optimal adhesion of the filler metal to the brass substrate.

Temperature Differences: Soldering vs Brazing Brass

Soft soldering brass typically occurs at temperatures below 450degF (232degC), using filler metals with low melting points to join components without melting the base brass. Brazing brass requires temperatures above 842degF (450degC), often between 1100degF and 1600degF (593degC to 871degC), utilizing stronger filler metals that create more durable and heat-resistant joints. The significant temperature difference impacts the structural integrity and applications of brass assemblies, with brazing providing superior mechanical strength compared to soft soldering.

Joint Strength: Comparing Soldered and Brazed Brass Connections

Brazed brass joints exhibit significantly higher strength compared to soft soldered connections, often reaching tensile strengths exceeding 60,000 psi, while soft soldered joints typically range between 20,000 to 30,000 psi. The metallurgical bond formed during brazing creates a robust, gap-filling joint that resists mechanical stress and thermal cycling better than soft soldered joints, which rely on lower melting point alloys such as tin-lead or tin-silver. For applications requiring enhanced durability and load-bearing capacity, brazing provides superior joint integrity in brass assemblies.

Filler Metals for Brass: Solder vs Brazing Alloys

Filler metals for soft soldering brass typically include lead-free solder alloys composed of tin, silver, and copper, which melt below 450degC, ensuring minimal thermal distortion of the brass components. Brazing alloys for brass often consist of copper-phosphorus or silver-based alloys, melting above 450degC, providing stronger, more durable joints suitable for high-pressure or high-temperature applications. Selection between solder and brazing alloys depends on mechanical strength requirements, corrosion resistance, and thermal exposure of the brass assembly.

Application Suitability: When to Solder vs When to Braze Brass

Soft soldering is suitable for delicate brass applications requiring low heat, such as electrical components and decorative items, where maintaining the brass's structural integrity is critical. Brazing is preferred for heavy-duty joints in brass plumbing, HVAC systems, and industrial fittings, providing stronger, more durable bonds capable of withstanding higher temperatures and mechanical stress. Selecting between soldering and brazing depends on the operational demands, joint strength requirements, and thermal exposure of the brass assembly.

Surface Preparation Requirements for Brass Joining

Effective surface preparation for brass joining varies significantly between soft soldering and brazing. Soft soldering demands thorough cleaning to remove oils, oxides, and contaminants, often involving mechanical abrasion and the use of flux to ensure proper wetting and adhesion. Brazing requires more rigorous surface cleaning and the removal of oxides, with flux or inert atmosphere protection essential to prevent oxidation during high-temperature joining, ensuring strong metallurgical bonds.

Equipment and Safety Considerations for Brass Joining

Soft soldering brass requires low-temperature equipment such as soldering irons or guns, allowing precise control to prevent base metal distortion, while fluxes are essential to ensure proper wetting and joint strength. Brazing brass involves higher temperature torches and specialized filler metals, necessitating protective gear like heat-resistant gloves and eye protection to guard against intense heat and bright flames. Proper ventilation is critical in both methods to avoid inhalation of potentially harmful fumes generated during the heating process.

Visual Quality and Finish: Soldered vs Brazed Brass

Soft soldering brass produces joints with a duller, less uniform appearance due to the lower melting point filler metals, resulting in visible solder lines and potential flux residues. Brazed brass joints exhibit a smooth, shiny finish with minimal discoloration, as the higher temperature filler metal creates stronger metallurgical bonds and cleaner surfaces. The visual quality and finish of brazed brass are preferred for decorative applications requiring seamless, polished aesthetics.

Cost and Efficiency Analysis: Soldering vs Brazing Brass

Soft soldering brass involves lower temperatures and less energy consumption, making it more cost-effective for small-scale or delicate assemblies. Brazing brass requires higher heat and more skilled labor but produces stronger, more durable joints suitable for high-stress applications. Efficiency in soldering is higher for quick repairs, whereas brazing offers long-term reliability, justifying its higher initial cost in industrial settings.

Soft Soldering vs Brazing (on Brass) Infographic

materialdif.com

materialdif.com