Electroplated brass features a thin layer of metal coating applied to a brass base, offering enhanced corrosion resistance and a polished finish at a lower cost. Solid brass is made entirely from brass alloy, providing superior durability, natural antimicrobial properties, and longer-lasting wear. Choosing between electroplated brass and solid brass depends on budget considerations and the desired strength and longevity for your project.

Table of Comparison

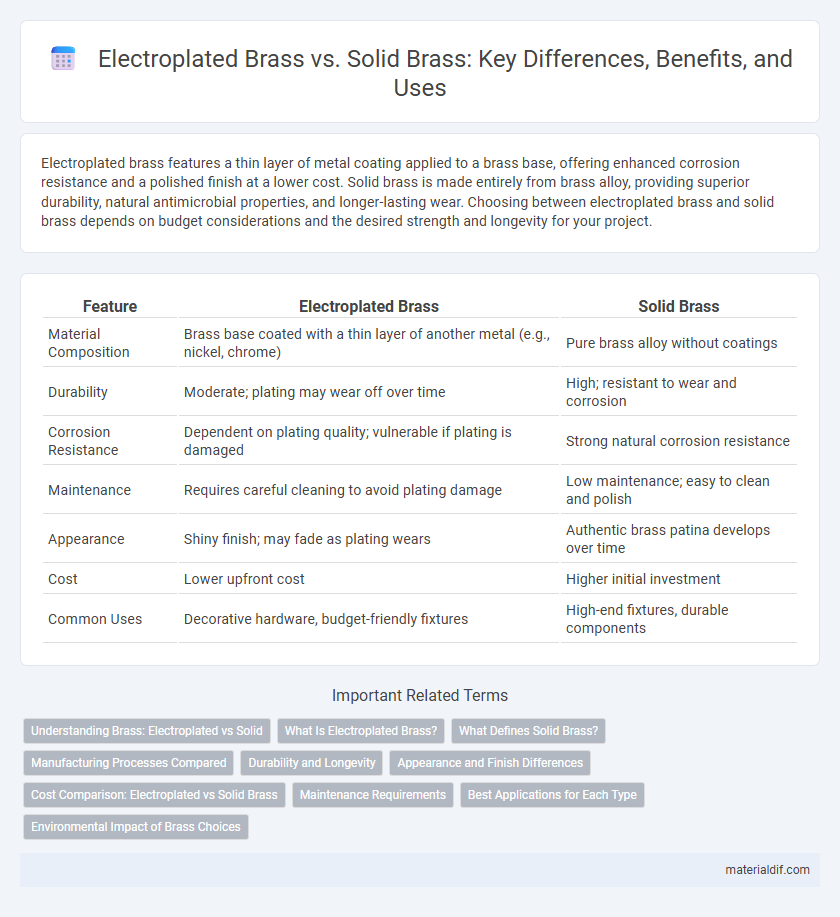

| Feature | Electroplated Brass | Solid Brass |

|---|---|---|

| Material Composition | Brass base coated with a thin layer of another metal (e.g., nickel, chrome) | Pure brass alloy without coatings |

| Durability | Moderate; plating may wear off over time | High; resistant to wear and corrosion |

| Corrosion Resistance | Dependent on plating quality; vulnerable if plating is damaged | Strong natural corrosion resistance |

| Maintenance | Requires careful cleaning to avoid plating damage | Low maintenance; easy to clean and polish |

| Appearance | Shiny finish; may fade as plating wears | Authentic brass patina develops over time |

| Cost | Lower upfront cost | Higher initial investment |

| Common Uses | Decorative hardware, budget-friendly fixtures | High-end fixtures, durable components |

Understanding Brass: Electroplated vs Solid

Electroplated brass features a thin layer of metal, often nickel or chrome, bonded onto a brass core, offering enhanced corrosion resistance and a polished finish while maintaining affordability. Solid brass consists entirely of brass alloy, providing superior durability, natural antimicrobial properties, and a heavier, more substantial feel ideal for long-lasting applications. Choosing between electroplated and solid brass depends on priorities such as budget, aesthetic longevity, and resistance to wear in specific environments.

What Is Electroplated Brass?

Electroplated brass consists of a base brass core coated with a thin layer of metal, typically nickel, chrome, or gold, through an electrochemical process that enhances corrosion resistance and aesthetic appeal. This process provides a durable finish that mimics the appearance of solid brass while significantly reducing costs and weight. Electroplated brass is widely used in decorative hardware, jewelry, and musical instruments to combine affordability with a high-quality metallic look.

What Defines Solid Brass?

Solid brass is defined by its composition of an alloy made primarily of copper and zinc, without any additional coating or plating. Its homogenous metal structure offers superior durability, corrosion resistance, and a heavier weight compared to electroplated brass. This intrinsic material quality ensures consistent performance and longevity in applications such as musical instruments, hardware, and decorative items.

Manufacturing Processes Compared

Electroplated brass involves applying a thin layer of metal, such as nickel or chrome, onto a brass base through an electrochemical process that enhances surface durability and corrosion resistance. Solid brass manufacturing entails casting or machining a homogeneous brass alloy, providing inherent strength, superior wear resistance, and consistent material properties throughout the component. The electroplating process adds aesthetic appeal and protection but may wear over time, while solid brass offers long-term reliability and structural integrity due to its uniform composition.

Durability and Longevity

Electroplated brass features a thin layer of metal coating that enhances corrosion resistance but can wear off over time, exposing the base metal to potential damage and reducing overall durability. Solid brass maintains consistent strength and corrosion resistance throughout the entire piece, offering superior longevity in high-use or outdoor environments. For applications requiring long-term resilience and minimal maintenance, solid brass outperforms electroplated brass due to its intrinsic material properties.

Appearance and Finish Differences

Electroplated brass features a thin layer of metal coating that provides a shiny, uniform appearance but may wear off over time, revealing the base brass underneath. Solid brass offers a natural, rich golden hue with a more durable finish that can develop a desirable patina, enhancing its aesthetic appeal. The choice between electroplated and solid brass impacts both the long-term appearance and maintenance requirements of the material.

Cost Comparison: Electroplated vs Solid Brass

Electroplated brass offers a cost-effective alternative to solid brass by applying a thin layer of brass over a less expensive metal, significantly reducing material expenses. Solid brass, made entirely from brass alloy, commands higher prices due to raw material costs and manufacturing processes. Choosing electroplated brass helps balance quality and budget, especially in large-scale production or decorative applications.

Maintenance Requirements

Electroplated brass features a thin layer of metal coating that requires gentle cleaning with non-abrasive materials to prevent peeling or discoloration. Solid brass, being a corrosion-resistant alloy, benefits from regular polishing with brass cleaners to maintain its natural shine and patina. Both materials demand routine care, but solid brass offers greater durability and longevity with fewer risks of surface damage.

Best Applications for Each Type

Electroplated brass offers enhanced corrosion resistance and aesthetic variety, making it ideal for decorative hardware, jewelry, and plumbing fixtures where surface finish is critical. Solid brass provides superior durability and malleability, which suits applications requiring structural integrity such as musical instruments, marine fittings, and high-stress mechanical components. Selecting the appropriate type depends on whether surface appearance or mechanical strength is the primary requirement.

Environmental Impact of Brass Choices

Electroplated brass involves coating a base metal with a thin layer of brass, which can result in chemical waste and energy-intensive processes during plating, contributing to environmental pollution. Solid brass, composed entirely of metal alloy, is more sustainable due to its recyclability and longer lifespan, reducing the need for frequent replacement and minimizing metal waste. Choosing solid brass supports eco-friendly manufacturing practices by decreasing toxic byproducts and promoting resource conservation.

Electroplated Brass vs Solid Brass Infographic

materialdif.com

materialdif.com