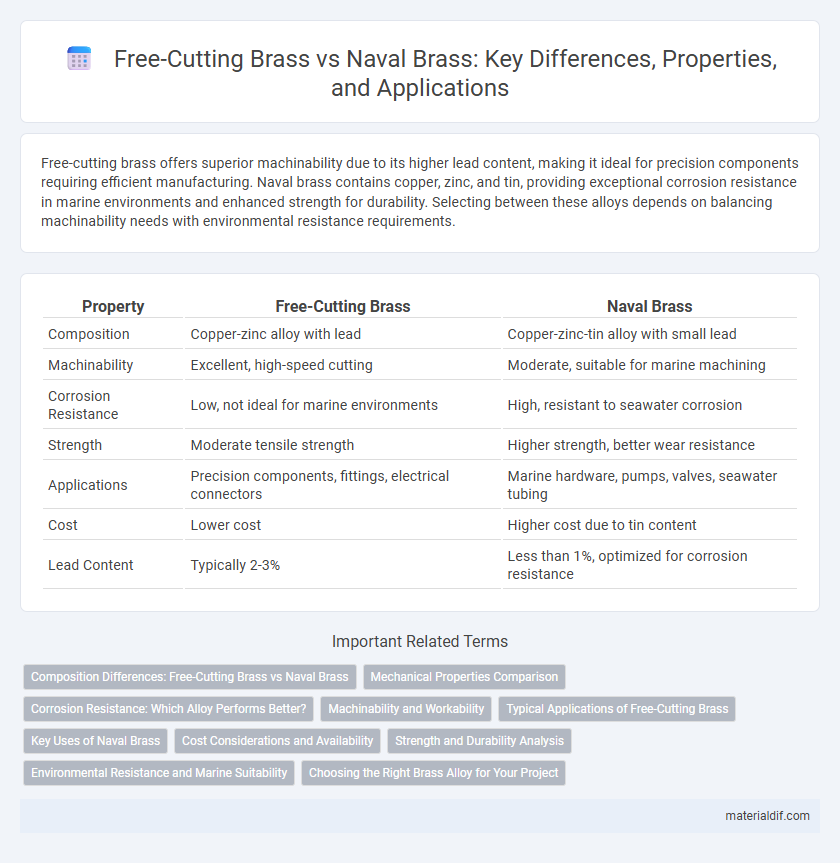

Free-cutting brass offers superior machinability due to its higher lead content, making it ideal for precision components requiring efficient manufacturing. Naval brass contains copper, zinc, and tin, providing exceptional corrosion resistance in marine environments and enhanced strength for durability. Selecting between these alloys depends on balancing machinability needs with environmental resistance requirements.

Table of Comparison

| Property | Free-Cutting Brass | Naval Brass |

|---|---|---|

| Composition | Copper-zinc alloy with lead | Copper-zinc-tin alloy with small lead |

| Machinability | Excellent, high-speed cutting | Moderate, suitable for marine machining |

| Corrosion Resistance | Low, not ideal for marine environments | High, resistant to seawater corrosion |

| Strength | Moderate tensile strength | Higher strength, better wear resistance |

| Applications | Precision components, fittings, electrical connectors | Marine hardware, pumps, valves, seawater tubing |

| Cost | Lower cost | Higher cost due to tin content |

| Lead Content | Typically 2-3% | Less than 1%, optimized for corrosion resistance |

Composition Differences: Free-Cutting Brass vs Naval Brass

Free-cutting brass typically contains around 36% zinc and small amounts of lead (approximately 2-3%) to enhance machinability, whereas naval brass has a composition of about 60% copper, 39% zinc, and 1% tin to improve corrosion resistance in marine environments. The lead in free-cutting brass reduces tool wear and improves chip formation during machining, while the tin in naval brass forms a protective oxide layer that enhances durability against saltwater corrosion. These compositional differences dictate the applications of each brass type, with free-cutting brass preferred for precision machining and naval brass used extensively in marine hardware.

Mechanical Properties Comparison

Free-cutting brass exhibits superior machinability due to its higher lead content, resulting in lower tensile strength and hardness compared to naval brass, which contains additional elements like tin for enhanced corrosion resistance and mechanical strength. Naval brass demonstrates greater tensile strength, typically around 550 MPa, and improved hardness, making it suitable for marine applications requiring durability under stress. The mechanical properties of free-cutting brass, with tensile strengths ranging from 250 to 350 MPa, are optimized for ease of machining rather than structural performance.

Corrosion Resistance: Which Alloy Performs Better?

Naval brass, an alloy typically consisting of copper, zinc, and a small percentage of tin, demonstrates superior corrosion resistance compared to free-cutting brass, which contains lead for enhanced machinability. The addition of tin in naval brass significantly improves resistance to seawater and chloride-induced corrosion, making it the preferred choice in marine environments. Free-cutting brass, while easier to machine, tends to corrode faster in aggressive environments, limiting its application in corrosive conditions.

Machinability and Workability

Free-cutting brass exhibits excellent machinability due to its higher lead content, which reduces tool wear and allows faster cutting speeds, making it ideal for precision machining. Naval brass, containing a higher percentage of copper and tin, offers superior corrosion resistance and durability but has lower machinability, requiring slower machining processes to prevent tool damage. Workability of free-cutting brass is enhanced by its softness and ability to be easily formed, while naval brass demands more careful handling due to its harder, more resilient structure.

Typical Applications of Free-Cutting Brass

Free-cutting brass, known for its high machinability and excellent chip-breaking properties, is widely used in manufacturing precision components such as screws, gears, and fittings. It is particularly favored in the automotive, electrical, and plumbing industries where complex shapes and tight tolerances are required. Typical applications include fasteners, valve components, and intricate turned parts that benefit from reduced machining time and improved surface finish.

Key Uses of Naval Brass

Naval brass, an alloy of copper, zinc, and tin, excels in marine environments due to its superior corrosion resistance and strength, making it ideal for ship fittings, propellers, and underwater valves. Unlike free-cutting brass, which is optimized for high machinability in manufacturing precision components such as screws and bolts, naval brass withstands harsh saltwater without deteriorating. Its durability in saltwater exposure ensures critical applications in naval and offshore industries where reliability and longevity are paramount.

Cost Considerations and Availability

Free-cutting brass typically offers lower material and machining costs due to its high machinability and widespread availability, making it ideal for high-volume manufacturing. Naval brass, often used for corrosion resistance in marine environments, usually commands a higher price and may have limited availability because of its specialized alloy composition. Budgeting for brass components requires balancing the cost-efficiency of free-cutting brass against the durability and performance benefits of naval brass in corrosive applications.

Strength and Durability Analysis

Free-cutting brass offers excellent machinability due to its higher lead content but typically exhibits lower strength and durability compared to naval brass, which contains added tin for enhanced corrosion resistance and mechanical properties. Naval brass demonstrates superior performance in harsh marine environments, maintaining structural integrity under stress and resisting dezincification better than free-cutting brass. Strength assessments reveal naval brass has higher tensile strength and fatigue resistance, making it more suitable for applications requiring durability in aggressive conditions.

Environmental Resistance and Marine Suitability

Free-cutting brass contains higher lead content, enhancing machinability but compromising corrosion resistance, making it less suitable for prolonged marine exposure. Naval brass, alloyed with tin and zinc, offers superior environmental resistance, especially against seawater corrosion, due to its robust microstructure. This durability makes naval brass a preferred choice for marine applications such as shipbuilding and underwater fittings.

Choosing the Right Brass Alloy for Your Project

Free-cutting brass offers superior machinability due to its lead content, making it ideal for precision components and intricate designs requiring efficient fabrication. Naval brass, containing higher copper and tin content with added zinc, excels in corrosion resistance and durability, especially in marine environments and applications exposed to saltwater. Selecting the right brass alloy depends on balancing machinability needs against environmental resistance requirements, ensuring optimal performance and longevity for your specific project.

Free-Cutting Brass vs Naval Brass Infographic

materialdif.com

materialdif.com