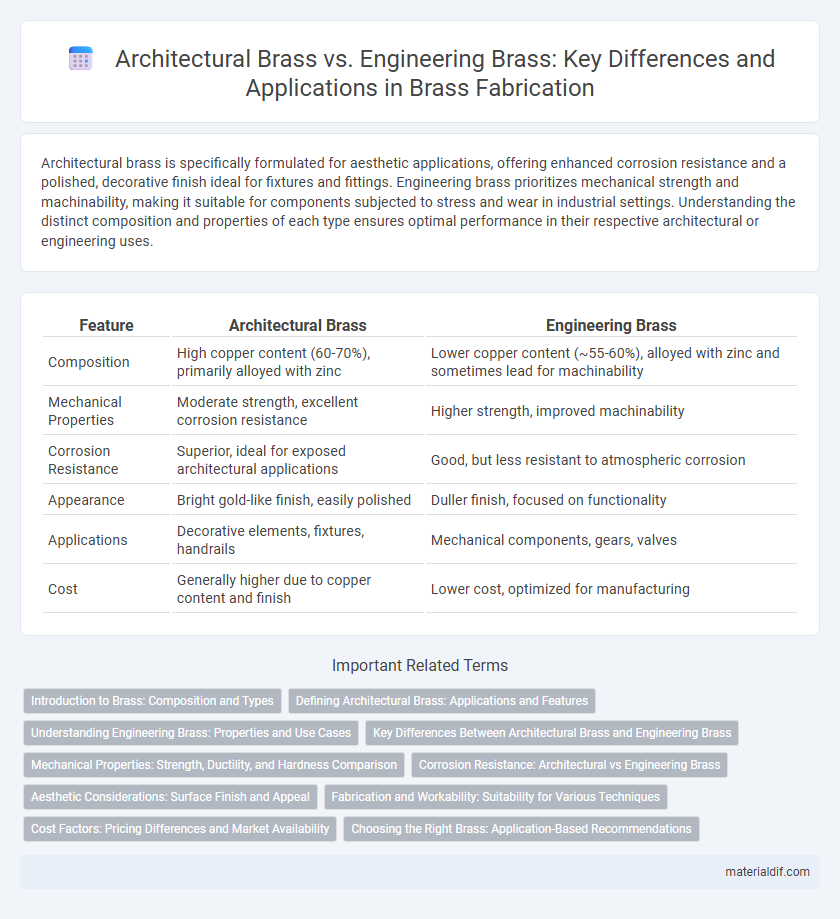

Architectural brass is specifically formulated for aesthetic applications, offering enhanced corrosion resistance and a polished, decorative finish ideal for fixtures and fittings. Engineering brass prioritizes mechanical strength and machinability, making it suitable for components subjected to stress and wear in industrial settings. Understanding the distinct composition and properties of each type ensures optimal performance in their respective architectural or engineering uses.

Table of Comparison

| Feature | Architectural Brass | Engineering Brass |

|---|---|---|

| Composition | High copper content (60-70%), primarily alloyed with zinc | Lower copper content (~55-60%), alloyed with zinc and sometimes lead for machinability |

| Mechanical Properties | Moderate strength, excellent corrosion resistance | Higher strength, improved machinability |

| Corrosion Resistance | Superior, ideal for exposed architectural applications | Good, but less resistant to atmospheric corrosion |

| Appearance | Bright gold-like finish, easily polished | Duller finish, focused on functionality |

| Applications | Decorative elements, fixtures, handrails | Mechanical components, gears, valves |

| Cost | Generally higher due to copper content and finish | Lower cost, optimized for manufacturing |

Introduction to Brass: Composition and Types

Architectural brass primarily consists of a high copper content alloy with zinc, designed for decorative applications requiring corrosion resistance and aesthetic appeal, typically containing around 60-70% copper. Engineering brass, often a low-leaded or lead-free alloy, balances machinability and strength with around 60-65% copper and additional elements like lead or tin to enhance mechanical properties for industrial use. Both types vary in composition to meet specific functional requirements, with architectural brass emphasizing appearance and durability, while engineering brass focuses on performance and ease of manufacturing.

Defining Architectural Brass: Applications and Features

Architectural brass is a specialized alloy known for its decorative appeal and corrosion resistance, commonly used in interior and exterior design elements such as door hardware, handrails, and ornamental fittings. It features a higher copper content and carefully controlled additives to enhance machinability and achieve a polished, aesthetically pleasing finish. Unlike engineering brass, which prioritizes mechanical strength and durability for industrial components, architectural brass balances functionality with visual impact, making it ideal for applications requiring both structural integrity and refined appearance.

Understanding Engineering Brass: Properties and Use Cases

Engineering brass, primarily composed of copper and zinc, offers superior machinability, strength, and corrosion resistance compared to architectural brass. It is commonly used in manufacturing mechanical parts such as gears, valves, and fittings that require durability and precision. Its enhanced tensile strength and thermal conductivity make it ideal for industrial applications where both performance and longevity are critical.

Key Differences Between Architectural Brass and Engineering Brass

Architectural brass primarily boasts superior corrosion resistance and an attractive finish, making it ideal for decorative applications such as handrails, fixtures, and trim in buildings. Engineering brass, on the other hand, emphasizes mechanical strength and machinability, commonly used in precision components like gears, valves, and fittings. The key differences lie in their alloy composition and physical properties, where architectural brass contains higher copper content for aesthetic appeal, while engineering brass incorporates elements like lead or tin to enhance durability and workability.

Mechanical Properties: Strength, Ductility, and Hardness Comparison

Architectural brass typically exhibits higher ductility and moderate strength, making it ideal for decorative applications requiring intricate shaping and forming. Engineering brass, in contrast, offers superior strength and hardness due to higher zinc content and specific alloying elements, enhancing its wear resistance and suitability for machining and structural components. The balance between hardness and ductility in engineering brass ensures durability under mechanical stress, while architectural brass prioritizes malleability for aesthetic versatility.

Corrosion Resistance: Architectural vs Engineering Brass

Architectural brass typically contains a higher copper content and lower zinc percentage, enhancing its corrosion resistance in outdoor and marine environments compared to engineering brass, which often includes lead to improve machinability but reduces corrosion resistance. The increased copper in architectural brass forms a protective patina that prevents rust and degradation over time, making it ideal for decorative facades, fixtures, and handrails. Engineering brass, used primarily for mechanical applications, sacrifices some corrosion resistance for strength and ease of manufacturing, requiring additional coatings or treatments to withstand corrosive conditions.

Aesthetic Considerations: Surface Finish and Appeal

Architectural brass is prized for its superior surface finish, offering a polished, bright appearance that enhances its aesthetic appeal in decorative applications such as fixtures and fittings. Engineering brass typically features a more utilitarian finish, prioritizing durability and machinability over visual qualities, making it less suitable for exposed decorative elements. The choice between these types depends on the desired balance between appearance and functional requirements in construction or design projects.

Fabrication and Workability: Suitability for Various Techniques

Architectural brass offers excellent workability for decorative techniques such as polishing, engraving, and etching due to its fine grain structure and higher copper content. Engineering brass, with its improved strength and machinability, is better suited for precision fabrication methods like CNC machining, casting, and forming in mechanical applications. Both types adapt well to soldering and brazing, but architectural brass's ease of shaping makes it preferable for intricate designs.

Cost Factors: Pricing Differences and Market Availability

Architectural brass typically commands a higher price due to its enhanced corrosion resistance, superior aesthetic finish, and specialized alloy composition, making it ideal for visible applications like fittings and decorative elements. Engineering brass often costs less as it is designed primarily for mechanical properties such as strength and machinability, commonly used in manufacturing and industrial components. Market availability affects pricing, with architectural brass sourced in smaller quantities and sometimes custom-finished, whereas engineering brass benefits from mass production and widespread distribution, influencing overall cost differences.

Choosing the Right Brass: Application-Based Recommendations

Architectural brass, typically composed of 59-65% copper and 35-41% zinc, offers superior corrosion resistance and aesthetic appeal, making it ideal for decorative fixtures, door hardware, and interior design elements. Engineering brass, often containing lead to enhance machinability, excels in mechanical applications requiring durability and precision such as valves, gears, and bearings. Selecting the right brass alloy depends on balancing corrosion resistance, machinability, and mechanical strength according to the specific demands of architectural or engineering projects.

Architectural Brass vs Engineering Brass Infographic

materialdif.com

materialdif.com