Free-cutting brass contains lead or other additives to enhance machinability, making it ideal for precision components requiring easy and fast manufacturing. High-tensile brass offers superior strength and durability, suited for applications involving heavy mechanical stress or structural support. Selecting between free-cutting and high-tensile brass depends on balancing the need for machining efficiency against strength requirements in the final product.

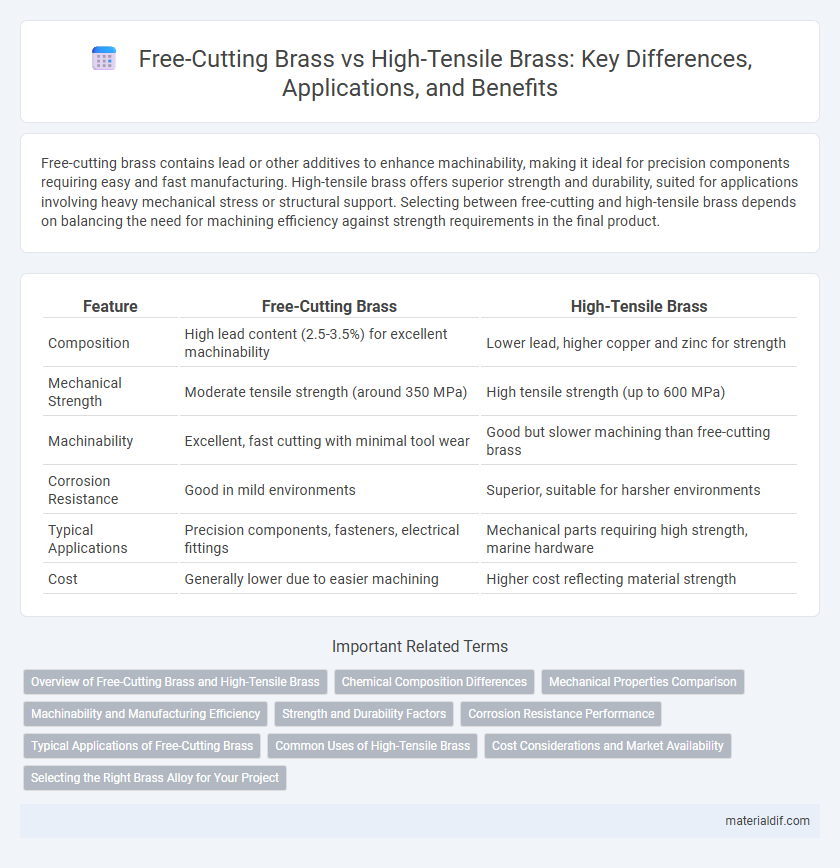

Table of Comparison

| Feature | Free-Cutting Brass | High-Tensile Brass |

|---|---|---|

| Composition | High lead content (2.5-3.5%) for excellent machinability | Lower lead, higher copper and zinc for strength |

| Mechanical Strength | Moderate tensile strength (around 350 MPa) | High tensile strength (up to 600 MPa) |

| Machinability | Excellent, fast cutting with minimal tool wear | Good but slower machining than free-cutting brass |

| Corrosion Resistance | Good in mild environments | Superior, suitable for harsher environments |

| Typical Applications | Precision components, fasteners, electrical fittings | Mechanical parts requiring high strength, marine hardware |

| Cost | Generally lower due to easier machining | Higher cost reflecting material strength |

Overview of Free-Cutting Brass and High-Tensile Brass

Free-cutting brass is engineered with added lead content, enhancing machinability and reducing tool wear, ideal for producing precision components with complex geometries. High-tensile brass offers superior strength and corrosion resistance, making it suitable for demanding structural applications requiring durability and longevity. Both types of brass alloys balance mechanical properties and machinability, tailored to specific industrial uses such as automotive parts, valves, and fittings.

Chemical Composition Differences

Free-cutting brass contains higher levels of lead, typically around 2-3%, which improves machinability by reducing tool wear and enhancing chip formation. In contrast, high-tensile brass has lower lead content, often below 1%, and increased amounts of zinc and copper to provide greater strength and corrosion resistance. These chemical composition differences directly influence their mechanical properties and suitability for different industrial applications.

Mechanical Properties Comparison

Free-cutting brass exhibits superior machinability due to its high lead content, which reduces tool wear and improves surface finish, making it ideal for precision machining. High-tensile brass features enhanced mechanical strength and hardness, achieved through higher copper and zinc ratios with limited lead, enabling greater resistance to deformation under stress. The choice between free-cutting and high-tensile brass depends on balancing machinability requirements against the need for mechanical durability in specific industrial applications.

Machinability and Manufacturing Efficiency

Free-cutting brass offers superior machinability due to its higher lead content, enabling faster cutting speeds and reduced tool wear, which significantly enhances manufacturing efficiency. High-tensile brass, containing less lead and higher strength alloys like zinc and tin, provides increased durability but requires slower machining and more frequent tool maintenance, leading to longer production times. Manufacturers often choose free-cutting brass for precision components requiring rapid fabrication, while high-tensile brass serves applications demanding greater mechanical strength despite lower machining efficiency.

Strength and Durability Factors

Free-cutting brass offers superior machinability due to its lead content, making it ideal for precision components but generally exhibits lower tensile strength and reduced durability under high-stress conditions. High-tensile brass, composed with higher copper and zinc ratios and minimal lead, delivers enhanced strength and wear resistance, suitable for heavy-duty applications where long-term durability is critical. Selecting between free-cutting and high-tensile brass depends on balancing ease of manufacturing with specific mechanical performance requirements.

Corrosion Resistance Performance

Free-cutting brass typically exhibits moderate corrosion resistance due to its higher lead content, which facilitates machining but can create micro-galvanic cells that accelerate corrosion. High-tensile brass, often alloyed with elements like aluminum and iron, demonstrates superior corrosion resistance by forming a more stable and protective oxide layer. For applications in harsh or marine environments, high-tensile brass provides enhanced durability and longer lifespan compared to free-cutting brass.

Typical Applications of Free-Cutting Brass

Free-cutting brass is commonly used in manufacturing precision components such as screws, pins, and small fittings due to its excellent machinability and smooth finish. Its fine grain structure and sulfur or lead content reduce tool wear, making it ideal for high-volume production in automotive, electrical, and plumbing industries. This alloy's ability to be easily machined without sacrificing corrosion resistance positions it as a preferred choice for intricate parts requiring tight tolerances.

Common Uses of High-Tensile Brass

High-tensile brass is commonly used in applications requiring superior strength and durability, such as automotive components, aerospace fittings, and industrial machinery parts. Its enhanced mechanical properties make it ideal for fasteners, valves, and gears exposed to high stress and wear. This alloy's resistance to deformation under load ensures reliable performance in demanding engineering environments.

Cost Considerations and Market Availability

Free-cutting brass typically offers lower production costs due to its enhanced machinability, reducing tool wear and cycle times, which makes it more cost-effective for high-volume manufacturing. High-tensile brass, while generally more expensive, provides superior strength and durability for applications requiring enhanced mechanical properties, but this can limit its market availability compared to the widely produced free-cutting variants. Market demand heavily influences pricing, with free-cutting brass being more readily available and budget-friendly, whereas high-tensile brass commands premium pricing and niche supply.

Selecting the Right Brass Alloy for Your Project

Free-cutting brass offers superior machinability with additives like lead or sulfur, making it ideal for intricate components requiring fast, precise manufacturing. High-tensile brass, enriched with aluminum or manganese, provides increased strength and durability, suitable for structural applications exposed to mechanical stress. Selecting the right brass alloy depends on balancing machinability needs with mechanical performance requirements to optimize production efficiency and product lifespan.

Free-Cutting Brass vs High-Tensile Brass Infographic

materialdif.com

materialdif.com