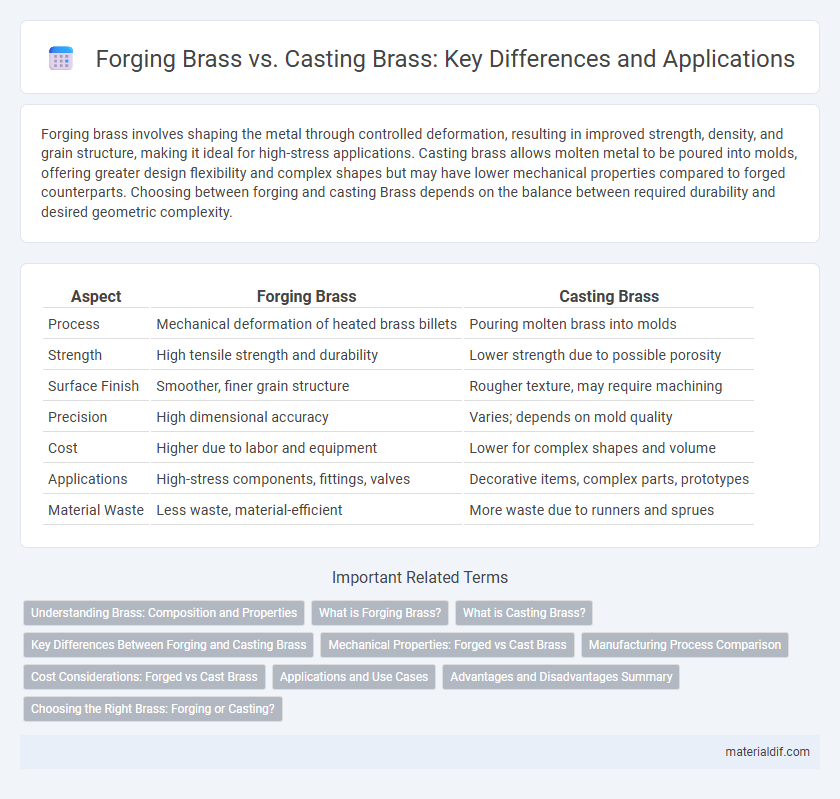

Forging brass involves shaping the metal through controlled deformation, resulting in improved strength, density, and grain structure, making it ideal for high-stress applications. Casting brass allows molten metal to be poured into molds, offering greater design flexibility and complex shapes but may have lower mechanical properties compared to forged counterparts. Choosing between forging and casting Brass depends on the balance between required durability and desired geometric complexity.

Table of Comparison

| Aspect | Forging Brass | Casting Brass |

|---|---|---|

| Process | Mechanical deformation of heated brass billets | Pouring molten brass into molds |

| Strength | High tensile strength and durability | Lower strength due to possible porosity |

| Surface Finish | Smoother, finer grain structure | Rougher texture, may require machining |

| Precision | High dimensional accuracy | Varies; depends on mold quality |

| Cost | Higher due to labor and equipment | Lower for complex shapes and volume |

| Applications | High-stress components, fittings, valves | Decorative items, complex parts, prototypes |

| Material Waste | Less waste, material-efficient | More waste due to runners and sprues |

Understanding Brass: Composition and Properties

Brass is an alloy primarily composed of copper and zinc, with varying zinc content influencing its mechanical properties such as strength, ductility, and corrosion resistance. Forging brass involves deforming the metal under high pressure, enhancing its grain structure and mechanical strength, making it suitable for high-stress applications. Casting brass, produced by melting and pouring into molds, allows complex shapes but results in coarser grain structure and slightly lower mechanical properties compared to forged brass.

What is Forging Brass?

Forging brass involves shaping the metal by applying compressive forces through hammering or pressing, which enhances its strength and durability by refining the grain structure. This process produces components with superior mechanical properties and improved resistance to fatigue and impact compared to casting. Forged brass is widely used in applications requiring high structural integrity, such as in plumbing fittings and precision instruments.

What is Casting Brass?

Casting brass involves melting the brass alloy and pouring it into a mold to create complex shapes with fine details and smooth surfaces. This process allows for the production of intricate components that would be difficult or impossible to achieve through forging. Casting brass is ideal for decorative items, plumbing fixtures, and automotive parts where precise shapes and detailed features are essential.

Key Differences Between Forging and Casting Brass

Forging brass involves shaping the metal through compressive forces, resulting in a denser, stronger material with improved mechanical properties and resistance to fatigue. Casting brass, on the other hand, entails pouring molten metal into molds, allowing for complex shapes and intricate designs but often producing parts with porosity and lower strength compared to forged counterparts. Key differences include forged brass's superior grain structure and durability versus cast brass's versatility in design and cost-effectiveness for mass production.

Mechanical Properties: Forged vs Cast Brass

Forged brass exhibits higher tensile strength and improved ductility due to the refined grain structure achieved through deformation processes, compared to cast brass which often has coarser grains and potential porosity. The mechanical properties of forged brass, including increased hardness and fatigue resistance, make it suitable for high-stress applications, whereas cast brass may demonstrate lower strength but better dimensional complexity. Forged brass typically provides superior impact resistance and superior overall durability in demanding mechanical environments.

Manufacturing Process Comparison

Forging brass involves shaping the metal under high pressure to enhance its grain structure, resulting in superior strength and durability compared to casting brass, which is poured into molds and solidifies with a more uniform but weaker grain structure. The forging process requires precise temperature control and powerful equipment to achieve the desired mechanical properties, whereas casting allows for more complex shapes with less mechanical stress but may introduce porosity or defects. Selecting between forging and casting brass depends on application requirements for strength, dimensional precision, and production volume in industries such as automotive, plumbing, and musical instruments.

Cost Considerations: Forged vs Cast Brass

Forging brass typically incurs higher costs due to the extensive labor, specialized equipment, and time required to shape the metal under high pressure, making it ideal for high-strength, precision applications. Casting brass offers a more cost-effective solution for complex shapes and lower production volumes, leveraging molten metal poured into molds with less post-processing needed. The choice between forged and cast brass hinges on balancing material strength requirements against budget constraints, where cast brass minimizes upfront expenses and forged brass delivers superior mechanical properties at a premium price.

Applications and Use Cases

Forging brass produces components with superior strength, making it ideal for high-stress applications such as marine fittings, automotive parts, and heavy-duty hardware. Casting brass allows for complex shapes and intricate designs, suitable for decorative items, intricate valve bodies, and artistic sculptures. Both methods are essential in manufacturing; forging ensures durability and performance, while casting offers versatility and cost-effectiveness for detailed or low-volume parts.

Advantages and Disadvantages Summary

Forging brass enhances mechanical strength and durability by aligning the metal's grain structure, making it ideal for high-stress applications, though it requires more energy and specialized equipment compared to casting. Casting brass allows for complex shapes and cost-effective production of intricate components, but it often results in lower strength and potential porosity issues. Selecting between forging and casting depends on balancing performance requirements with manufacturing costs and design complexity.

Choosing the Right Brass: Forging or Casting?

Choosing the right brass between forging and casting depends on the application's strength and precision requirements. Forged brass exhibits superior mechanical properties, including enhanced tensile strength and durability, making it ideal for high-stress components like valves and fittings. Casting brass allows for complex shapes and detailed designs but typically has lower strength, suitable for decorative or less load-intensive parts.

Forging Brass vs Casting Brass Infographic

materialdif.com

materialdif.com