Brass pet offers excellent machinability due to its fine grain structure and low friction properties, allowing for precise and efficient cutting processes. However, its ductility is moderately lower compared to other brass alloys, which may limit its ability to undergo significant deformation without cracking. Balancing machinability and ductility in brass pet ensures optimal performance for applications requiring intricate machining while maintaining sufficient material flexibility.

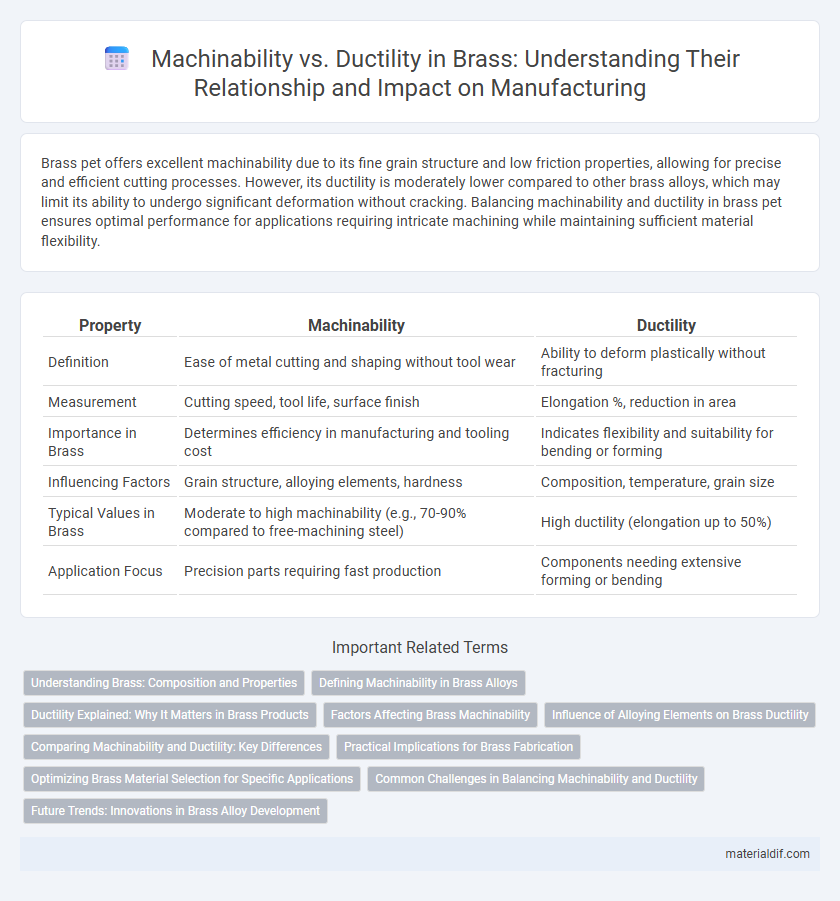

Table of Comparison

| Property | Machinability | Ductility |

|---|---|---|

| Definition | Ease of metal cutting and shaping without tool wear | Ability to deform plastically without fracturing |

| Measurement | Cutting speed, tool life, surface finish | Elongation %, reduction in area |

| Importance in Brass | Determines efficiency in manufacturing and tooling cost | Indicates flexibility and suitability for bending or forming |

| Influencing Factors | Grain structure, alloying elements, hardness | Composition, temperature, grain size |

| Typical Values in Brass | Moderate to high machinability (e.g., 70-90% compared to free-machining steel) | High ductility (elongation up to 50%) |

| Application Focus | Precision parts requiring fast production | Components needing extensive forming or bending |

Understanding Brass: Composition and Properties

Brass, primarily composed of copper and zinc, balances machinability and ductility through its alloying elements; higher zinc content typically increases machinability but reduces ductility. The machinability of brass alloys, such as free-cutting brass with added lead, enhances tool life and surface finish, making it ideal for precision components. Conversely, brasses with greater copper content exhibit superior ductility, allowing extensive deformation without fracture, which is crucial for applications requiring bending and shaping.

Defining Machinability in Brass Alloys

Machinability in brass alloys refers to the ease with which the material can be cut, shaped, or finished using machining processes, directly impacting manufacturing efficiency and surface quality. It depends on factors such as alloy composition, microstructure, and hardness, with leaded brasses often exhibiting superior machinability due to the lubricating effect of lead particles. Ductility, the ability to deform plastically without fracturing, differs from machinability but influences machining by affecting chip formation and tool wear during cutting operations.

Ductility Explained: Why It Matters in Brass Products

Ductility in brass is a critical property that defines its ability to undergo significant plastic deformation without fracturing, essential for manufacturing processes like bending, drawing, and forming. High ductility in brass alloys ensures better machinability by reducing tool wear and enabling complex shapes without cracking, making it ideal for plumbing fixtures, musical instruments, and precision components. Understanding the balance between machinability and ductility allows engineers to select the appropriate brass grade, such as cartridge brass (70% copper, 30% zinc) known for superior ductility and ease of machining.

Factors Affecting Brass Machinability

Brass machinability is influenced by factors such as alloy composition, with leaded brass exhibiting superior cutting performance due to improved chip formation and reduced tool wear. Grain structure and hardness also play crucial roles, where finer grains and moderate hardness enhance machinability without compromising ductility. Lubrication and cutting speed further affect tool life and surface finish during brass machining processes.

Influence of Alloying Elements on Brass Ductility

Alloying elements such as zinc, lead, and tin significantly influence brass ductility, with zinc typically reducing ductility while improving strength and machinability. Lead additions enhance machinability by promoting chip breaking but may slightly reduce ductility due to inclusions. Tin increases corrosion resistance and can maintain or slightly improve ductility, balancing strength and formability in brass alloys.

Comparing Machinability and Ductility: Key Differences

Brass exhibits high machinability due to its relatively low hardness and excellent chip formation, making it ideal for precise machining processes. In contrast, its ductility allows the metal to deform under tensile stress without fracturing, enabling forming and shaping operations such as bending and drawing. While machinability emphasizes ease of cutting and tool wear reduction, ductility focuses on the metal's capacity to undergo plastic deformation without failure, both critical properties influencing brass's versatility in manufacturing.

Practical Implications for Brass Fabrication

Brass exhibits a favorable balance between machinability and ductility, enabling efficient cutting while maintaining the metal's ability to deform without cracking during fabrication. High machinability in brass alloys reduces tool wear and processing time, making it ideal for precision components, whereas adequate ductility ensures successful forming techniques like bending and deep drawing. Selecting brass grades with optimized machinability and ductility is crucial for applications requiring intricate shapes and reliable mechanical performance.

Optimizing Brass Material Selection for Specific Applications

Brass exhibits excellent machinability due to its low friction and chip-breaking properties, making it ideal for precision machining processes such as CNC turning and milling. However, optimizing brass material selection requires balancing machinability with ductility to ensure durability and formability in applications like electrical connectors and plumbing fittings. Selecting alloys such as C36000 offers high machinability, while alloys like C46400 provide enhanced ductility for forming-intensive tasks, enabling tailored performance for specific industrial uses.

Common Challenges in Balancing Machinability and Ductility

Balancing machinability and ductility in brass alloys presents challenges due to their conflicting material properties; enhanced machinability often requires alloying elements like lead, which can reduce ductility and impact mechanical strength. Optimizing leaded brass grades such as C360 improves chip formation and surface finish but compromises elongation and toughness. Achieving an ideal balance requires precise control of alloy composition and heat treatment to maintain sufficient ductility for forming while ensuring efficient machining processes.

Future Trends: Innovations in Brass Alloy Development

Advancements in brass alloy development emphasize enhancing machinability without compromising ductility, driven by innovations in microalloying and heat treatment techniques. Emerging brass compositions utilize precise elemental adjustments like adding bismuth or selenium to optimize chip formation and surface finish during machining processes. Future trends prioritize sustainable manufacturing methods and alloy designs that balance mechanical performance with environmental impact for industrial applications.

Machinability vs Ductility Infographic

materialdif.com

materialdif.com