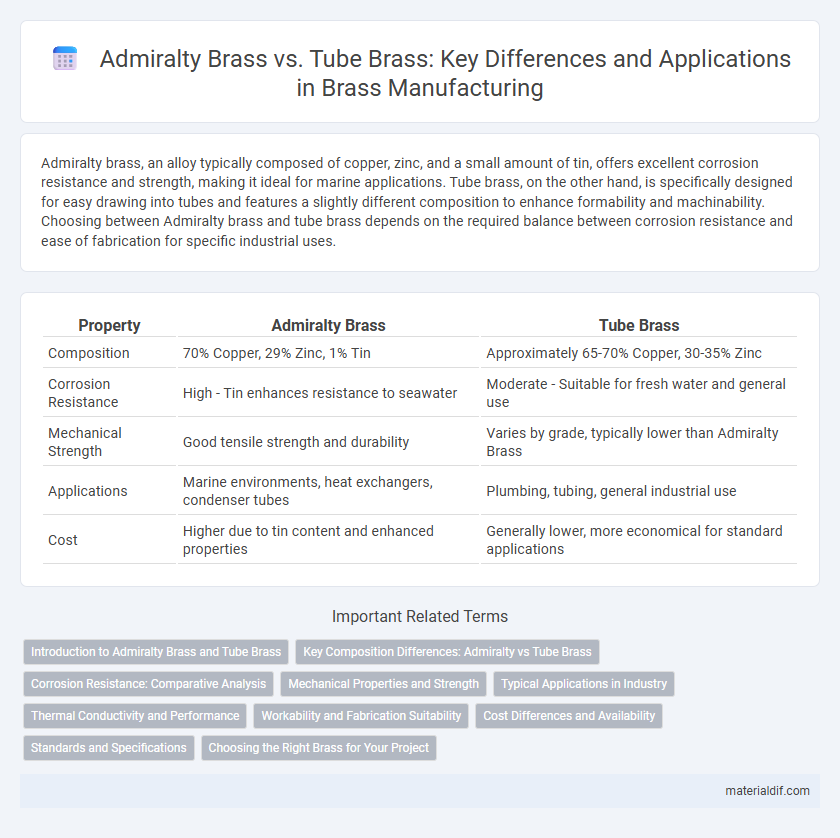

Admiralty brass, an alloy typically composed of copper, zinc, and a small amount of tin, offers excellent corrosion resistance and strength, making it ideal for marine applications. Tube brass, on the other hand, is specifically designed for easy drawing into tubes and features a slightly different composition to enhance formability and machinability. Choosing between Admiralty brass and tube brass depends on the required balance between corrosion resistance and ease of fabrication for specific industrial uses.

Table of Comparison

| Property | Admiralty Brass | Tube Brass |

|---|---|---|

| Composition | 70% Copper, 29% Zinc, 1% Tin | Approximately 65-70% Copper, 30-35% Zinc |

| Corrosion Resistance | High - Tin enhances resistance to seawater | Moderate - Suitable for fresh water and general use |

| Mechanical Strength | Good tensile strength and durability | Varies by grade, typically lower than Admiralty Brass |

| Applications | Marine environments, heat exchangers, condenser tubes | Plumbing, tubing, general industrial use |

| Cost | Higher due to tin content and enhanced properties | Generally lower, more economical for standard applications |

Introduction to Admiralty Brass and Tube Brass

Admiralty Brass is a high-quality alloy composed primarily of copper, zinc, and a small percentage of tin, known for excellent corrosion resistance in seawater environments, making it ideal for marine applications. Tube Brass, typically a variant of standard brass with optimized dimensions and mechanical properties, is designed specifically for manufacturing seamless tubes used in plumbing, heat exchangers, and industrial piping. Admiralty Brass offers superior durability against dezincification compared to Tube Brass, which prioritizes ease of fabrication and cost-efficiency for tubular components.

Key Composition Differences: Admiralty vs Tube Brass

Admiralty Brass typically contains about 70% copper, 29% zinc, and around 1% tin, which enhances its corrosion resistance and durability, especially in marine environments. Tube Brass, commonly composed of approximately 60-70% copper and 30-40% zinc without tin, offers excellent machinability and is primarily used for tubing and heat exchanger applications. The key compositional difference lies in the presence of tin in Admiralty Brass, providing superior corrosion resistance compared to the higher zinc content and absence of tin in Tube Brass.

Corrosion Resistance: Comparative Analysis

Admiralty brass exhibits superior corrosion resistance due to its tin content, which enhances protection against seawater and chloride-induced corrosion, making it ideal for marine applications. Tube brass, typically a zinc-copper alloy with lower tin levels, demonstrates moderate corrosion resistance but is more susceptible to dezincification in aggressive environments. The comparative analysis highlights Admiralty brass as the preferred choice for high-corrosion settings, while tube brass suits less demanding applications.

Mechanical Properties and Strength

Admiralty Brass typically offers higher tensile strength and superior corrosion resistance compared to Tube Brass, making it well-suited for marine and high-stress applications. Tube Brass, while having slightly lower mechanical strength, provides excellent machinability and formability for tubing projects requiring precision and flexibility. The enhanced strength of Admiralty Brass is attributed to its specific alloy composition, including higher copper and tin content, which improves hardness and durability under mechanical loads.

Typical Applications in Industry

Admiralty Brass is commonly used in marine hardware, heat exchangers, and condensers due to its excellent corrosion resistance in seawater environments. Tube Brass is typically applied in the manufacturing of plumbing tubes, heat exchanger tubes, and condenser tubes where good machinability and thermal conductivity are required. Both materials are favored for their durability and resistance to dezincification in industrial applications.

Thermal Conductivity and Performance

Admiralty Brass, composed primarily of copper, zinc, and a small percentage of tin, offers a thermal conductivity of approximately 120 W/m*K, making it suitable for marine applications requiring corrosion resistance and efficient heat dissipation. Tube Brass, often a type of dezincification-resistant brass with variations in zinc content, typically has slightly lower thermal conductivity, around 100-110 W/m*K, yet provides enhanced mechanical strength for tubing and heat exchanger performance. The choice between Admiralty Brass and Tube Brass depends on balancing thermal conductivity requirements with corrosion resistance and mechanical properties for optimal application performance.

Workability and Fabrication Suitability

Admiralty Brass, composed primarily of copper, zinc, and a small amount of tin, exhibits excellent corrosion resistance and good machinability, making it suitable for marine applications but requires careful handling during fabrication due to its higher brittleness compared to Tube Brass. Tube Brass, typically an alpha-beta brass alloy with higher zinc content, offers superior workability, allowing easier bending, drawing, and welding, which makes it ideal for tubing and general fabrication processes. The choice between Admiralty Brass and Tube Brass depends on the desired balance between corrosion resistance and ease of fabrication in the specific application.

Cost Differences and Availability

Admiralty Brass typically costs more than Tube Brass due to its higher copper content and superior corrosion resistance, making it ideal for marine applications. Tube Brass is more readily available and generally less expensive due to its wider use in plumbing and HVAC systems. The cost difference reflects Admiralty Brass's specialized alloying elements like arsenic, which enhance durability but increase price.

Standards and Specifications

Admiralty Brass conforms to ASTM B30 standards, featuring high copper content (approximately 70%) with additions of tin and zinc to enhance corrosion resistance, primarily used in marine applications due to its superior resistance to dezincification. Tube Brass adheres to ASTM B135 specifications, characterized by a higher zinc content (around 65%) compared to Admiralty Brass, designed for machinability and typically employed in tubing and condenser tubes. Both materials meet rigorous industry standards but differ in composition and application focus, impacting their selection based on environmental resistance and mechanical properties.

Choosing the Right Brass for Your Project

Admiralty Brass, known for its high corrosion resistance due to its addition of tin, is ideal for marine applications where durability against seawater is critical. Tube Brass offers excellent machinability and strength, making it suitable for plumbing and heat exchanger tubes requiring precise fabrication. Selecting the right brass depends on environmental exposure and mechanical requirements, with Admiralty Brass favored for harsh, wet conditions and Tube Brass preferred for structural and thermal conductivity needs.

Admiralty Brass vs Tube Brass Infographic

materialdif.com

materialdif.com