Admiralty Brass is an alloy composed primarily of copper, zinc, and a small amount of tin, providing excellent corrosion resistance and strength, especially in seawater applications. Muntz Metal, also known as yellow metal, consists mainly of copper and zinc with a higher zinc content than Admiralty Brass, offering superior wear resistance but slightly less corrosion resistance. When choosing between Admiralty Brass and Muntz Metal, consider Admiralty Brass for marine environments requiring higher corrosion resistance, while Muntz Metal suits applications demanding enhanced durability and wear resistance.

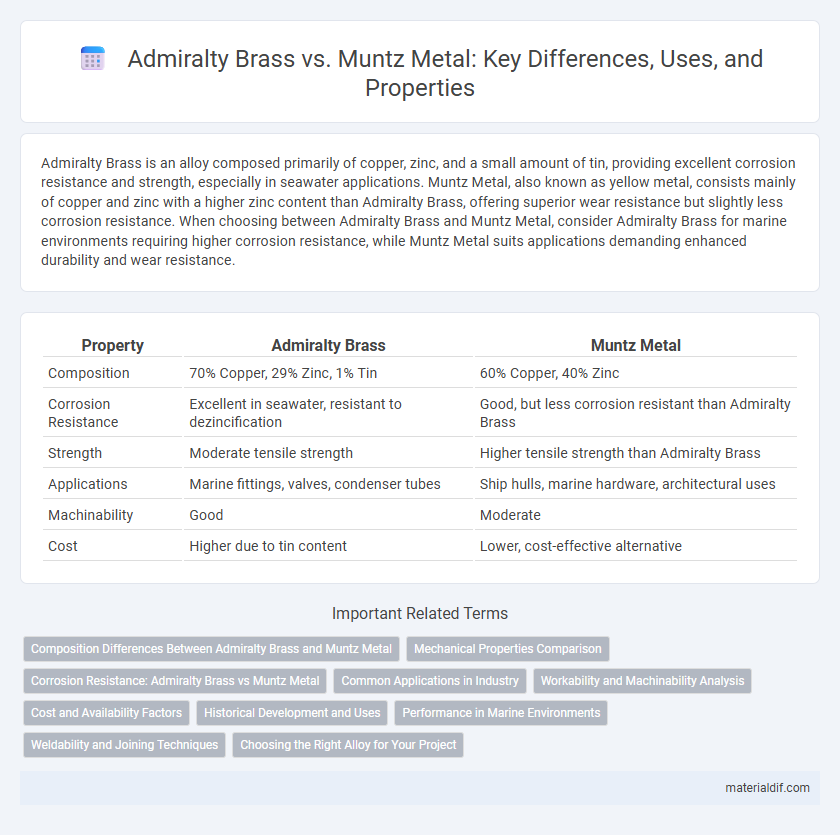

Table of Comparison

| Property | Admiralty Brass | Muntz Metal |

|---|---|---|

| Composition | 70% Copper, 29% Zinc, 1% Tin | 60% Copper, 40% Zinc |

| Corrosion Resistance | Excellent in seawater, resistant to dezincification | Good, but less corrosion resistant than Admiralty Brass |

| Strength | Moderate tensile strength | Higher tensile strength than Admiralty Brass |

| Applications | Marine fittings, valves, condenser tubes | Ship hulls, marine hardware, architectural uses |

| Machinability | Good | Moderate |

| Cost | Higher due to tin content | Lower, cost-effective alternative |

Composition Differences Between Admiralty Brass and Muntz Metal

Admiralty brass primarily consists of approximately 70% copper, 29% zinc, and 1% tin, enhancing its corrosion resistance and strength, particularly in marine environments. Muntz metal, on the other hand, contains about 60% copper and 40% zinc, lacking tin, which results in lower corrosion resistance but higher malleability and ease of casting. The presence of tin in Admiralty brass significantly improves its suitability for seawater applications, whereas Muntz metal is often favored where cost-effectiveness and workability are prioritized.

Mechanical Properties Comparison

Admiralty brass, composed primarily of copper, zinc, and tin, exhibits superior corrosion resistance and tensile strength, making it suitable for marine applications. Muntz metal, an alloy of copper and zinc with higher zinc content, offers enhanced hardness and wear resistance but lower ductility compared to Admiralty brass. Mechanical properties show Admiralty brass with tensile strength around 550 MPa and elongation about 25%, while Muntz metal has tensile strength near 450 MPa and elongation closer to 15%.

Corrosion Resistance: Admiralty Brass vs Muntz Metal

Admiralty Brass exhibits superior corrosion resistance compared to Muntz Metal, primarily due to its higher copper content and inclusion of tin, which enhances its durability in marine environments. Muntz Metal, an alloy of approximately 60% copper and 40% zinc, is more prone to dezincification and corrosion when exposed to saltwater, limiting its longevity in seawater applications. Admiralty Brass's balanced composition of copper (70%), zinc (29%), and tin (1%) provides enhanced resistance to stress corrosion cracking, making it a preferred material for marine hardware and fittings.

Common Applications in Industry

Admiralty Brass, characterized by its high copper and tin content with a small percentage of zinc, is widely used in marine environments for seawater applications such as shipbuilding, heat exchanger tubes, and condenser tubes due to its excellent corrosion resistance. Muntz Metal, an alloy of approximately 60% copper and 40% zinc, finds extensive applications in marine hardware, roofing, and automotive parts where durability and resistance to atmospheric corrosion are critical. Both alloys serve crucial roles in industrial uses where resistance to seawater corrosion and mechanical strength are required, but Admiralty Brass is preferred for more corrosive saltwater environments while Muntz Metal suits less aggressive atmospheres.

Workability and Machinability Analysis

Admiralty Brass exhibits excellent workability due to its lower zinc content and addition of tin, making it highly resistant to dezincification and corrosion, which benefits marine applications. Muntz Metal, an alloy primarily of copper and zinc with a higher zinc percentage, offers superior machinability but is more prone to corrosion compared to Admiralty Brass. The machinability of Muntz Metal is enhanced by its composition, allowing faster cutting speeds and smoother finishes, whereas Admiralty Brass requires more careful machining to avoid surface defects.

Cost and Availability Factors

Admiralty Brass, composed primarily of copper, zinc, and tin, tends to be more expensive due to its specialized corrosion-resistant properties and limited supply compared to Muntz Metal, which is a form of cheaper, more readily available brass alloy with a higher zinc content. Muntz Metal's widespread production and lower material costs make it a cost-effective choice for large-scale applications, whereas Admiralty Brass is preferred for marine environments despite higher initial investment. Supply chain factors further influence pricing, with Admiralty Brass often encountering longer lead times due to the inclusion of tin, a less abundant element than the constituents of Muntz Metal.

Historical Development and Uses

Admiralty Brass, developed in the early 20th century, is a high-quality copper-zinc alloy with added tin, designed to resist dezincification and corrosion in marine environments, making it ideal for ship fittings and seawater applications. Muntz Metal, invented in 1832 by George Fredrick Muntz, is a brass alloy with approximately 60% copper and 40% zinc, known for its strength and affordability, commonly used for hull sheathing on ships to prevent biofouling. Both alloys played crucial roles in naval engineering, with Admiralty Brass favored for precision components and Muntz Metal for protective external plating.

Performance in Marine Environments

Admiralty Brass exhibits superior corrosion resistance and durability in marine environments due to its high copper and zinc content, enhanced by a small percentage of tin that improves its resistance to dezincification. Muntz Metal, composed primarily of 60% copper and 40% zinc, offers good strength and moderate corrosion resistance but is more susceptible to dezincification and stress corrosion cracking in seawater compared to Admiralty Brass. The enhanced performance of Admiralty Brass makes it ideal for marine fittings and components subjected to harsh seawater conditions.

Weldability and Joining Techniques

Admiralty Brass, an alloy of copper, zinc, and tin, offers excellent weldability using traditional fusion welding methods due to its lower zinc content and minimal dezincification risk. Muntz Metal, composed of approximately 60% copper and 40% zinc, requires specialized joining techniques like brazing or soldering to prevent hot cracking and zinc loss during welding. Both materials benefit from controlled heat input and proper filler metals to maintain structural integrity in marine and industrial applications.

Choosing the Right Alloy for Your Project

Admiralty Brass, composed of copper, zinc, and a small percentage of tin, offers excellent corrosion resistance and durability, making it ideal for marine and industrial applications where exposure to seawater is common. Muntz Metal, an alloy of copper and zinc with a higher zinc content than Admiralty Brass, provides superior strength and wear resistance, suitable for hull sheathing and heavy-duty marine hardware. Selecting the right alloy depends on balancing corrosion resistance and mechanical strength requirements specific to your project's environmental conditions and load demands.

Admiralty Brass vs Muntz Metal Infographic

materialdif.com

materialdif.com