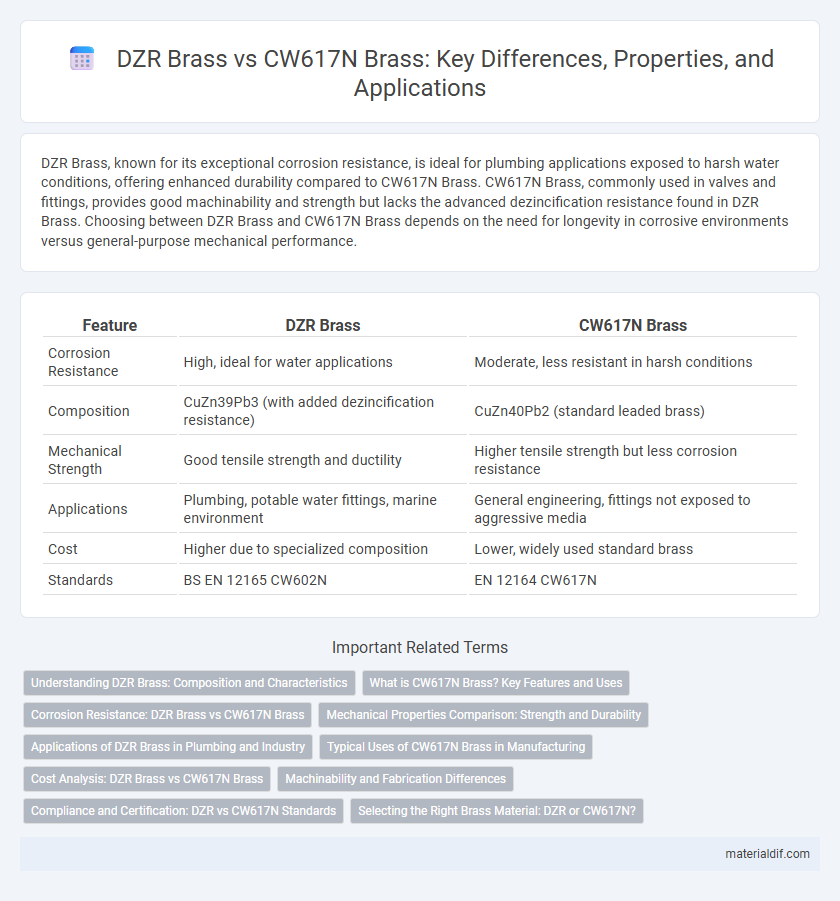

DZR Brass, known for its exceptional corrosion resistance, is ideal for plumbing applications exposed to harsh water conditions, offering enhanced durability compared to CW617N Brass. CW617N Brass, commonly used in valves and fittings, provides good machinability and strength but lacks the advanced dezincification resistance found in DZR Brass. Choosing between DZR Brass and CW617N Brass depends on the need for longevity in corrosive environments versus general-purpose mechanical performance.

Table of Comparison

| Feature | DZR Brass | CW617N Brass |

|---|---|---|

| Corrosion Resistance | High, ideal for water applications | Moderate, less resistant in harsh conditions |

| Composition | CuZn39Pb3 (with added dezincification resistance) | CuZn40Pb2 (standard leaded brass) |

| Mechanical Strength | Good tensile strength and ductility | Higher tensile strength but less corrosion resistance |

| Applications | Plumbing, potable water fittings, marine environment | General engineering, fittings not exposed to aggressive media |

| Cost | Higher due to specialized composition | Lower, widely used standard brass |

| Standards | BS EN 12165 CW602N | EN 12164 CW617N |

Understanding DZR Brass: Composition and Characteristics

DZR Brass, or Dezincification Resistant Brass, is an alloy primarily composed of copper, zinc, and a small percentage of phosphorus to enhance its corrosion resistance properties. Unlike CW617N Brass, which typically contains around 60% copper and 39% zinc, DZR Brass has a modified composition that reduces zinc content and incorporates strategic additives to prevent dezincification in aggressive water environments. These characteristics make DZR Brass particularly suited for plumbing applications where durability and resistance to dezincification are critical.

What is CW617N Brass? Key Features and Uses

CW617N brass, also known as dezincification-resistant (DZR) brass, is an alloy primarily composed of copper, zinc, and a small amount of lead, designed to resist corrosion and dezincification in plumbing applications. Key features of CW617N brass include high machinability, excellent corrosion resistance, and durability in potable water systems, making it ideal for fittings, valves, and taps. Its use is widespread in water supply components where reliability and resistance to dezincification are critical for long-term performance.

Corrosion Resistance: DZR Brass vs CW617N Brass

DZR Brass (Dezincification Resistant Brass) offers superior corrosion resistance compared to CW617N Brass, particularly in plumbing applications exposed to aggressive water conditions. The enhanced alloy composition of DZR Brass significantly reduces the risk of dezincification, maintaining structural integrity over time. CW617N Brass, while durable, is more susceptible to dezincification, making DZR Brass the preferred choice for long-term corrosion resistance in water systems.

Mechanical Properties Comparison: Strength and Durability

DZR Brass, known for its dezincification resistance, exhibits superior corrosion resistance compared to CW617N Brass, making it more durable in water-related applications. CW617N Brass, a standard brass alloy, offers higher tensile strength but lower resistance to dezincification, potentially reducing its longevity in harsh environments. The mechanical strength of CW617N supports high-pressure tolerance, while DZR Brass's enhanced durability ensures extended service life in plumbing and marine settings.

Applications of DZR Brass in Plumbing and Industry

DZR Brass, also known as dezincification-resistant brass, is extensively used in plumbing applications requiring high corrosion resistance, such as potable water fittings and valves. Its enhanced durability against dezincification makes it ideal for industrial environments exposed to aggressive water conditions and chemical agents. Unlike CW617N brass, DZR Brass ensures longer service life and reliability in critical water supply and heating systems.

Typical Uses of CW617N Brass in Manufacturing

CW617N brass, known for its excellent machinability and corrosion resistance, is commonly used in the manufacturing of plumbing fittings, valves, and electrical components. Its superior durability and strength make it ideal for applications requiring reliable performance in water and gas distribution systems. This alloy's ability to withstand mechanical stress ensures longevity in industrial and residential installations.

Cost Analysis: DZR Brass vs CW617N Brass

DZR Brass typically incurs higher initial costs compared to CW617N Brass due to its enhanced dezincification resistance and copper-rich composition, making it suitable for long-term applications in aggressive water environments. CW617N Brass offers more cost-effective pricing with acceptable mechanical properties and corrosion resistance for general plumbing uses where dezincification risk is lower. Evaluating total lifecycle expenses shows that investing in DZR Brass can minimize maintenance and replacement costs in critical installations despite the higher upfront expenditure.

Machinability and Fabrication Differences

DZR Brass, also known as dezincification resistant brass, offers superior corrosion resistance compared to CW617N Brass, making it ideal for plumbing and marine applications. CW617N Brass, with its higher machinability rating, is preferred for intricate machining and mass production due to easier chip removal and faster tooling speeds. Fabrication of DZR Brass requires more precise control of cutting parameters to avoid tool wear, while CW617N Brass allows for more aggressive machining with less risk of dezincification.

Compliance and Certification: DZR vs CW617N Standards

DZR Brass complies with BS EN 12165 CW602N standards, ensuring enhanced dezincification resistance and certification for potable water systems, meeting stringent EU regulations for lead content. CW617N Brass, conforming to EN 12164, is widely accepted for general plumbing but exhibits lower resistance to dezincification, impacting long-term durability in aggressive water environments. Certification differences highlight DZR Brass as the preferred choice for critical potable water applications requiring robust compliance with health and safety standards.

Selecting the Right Brass Material: DZR or CW617N?

DZR Brass, also known as dezincification-resistant brass, offers superior corrosion resistance in water environments, making it ideal for plumbing and marine applications. CW617N Brass is a high-quality, versatile alloy commonly used in general-purpose valve and fitting manufacturing due to its excellent machinability and mechanical strength. Selecting between DZR and CW617N brass depends on the application's exposure to corrosive conditions, with DZR preferred for longevity in harsh settings and CW617N suited for standard industrial use.

DZR Brass vs CW617N Brass Infographic

materialdif.com

materialdif.com