Machining brass allows for precise, intricate shapes and tight tolerances, making it ideal for custom components and detailed designs. Forming brass, through processes like stamping or bending, offers faster production and cost efficiency for simpler, high-volume parts. Selecting between machining and forming depends on the complexity, quantity, and specific mechanical properties required in the finished brass product.

Table of Comparison

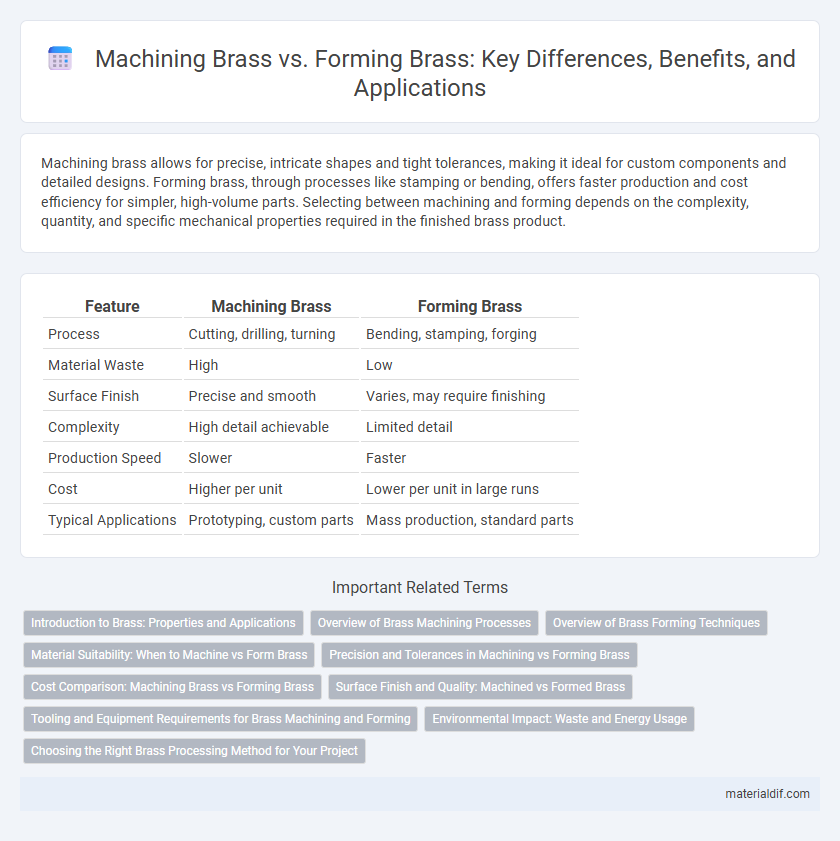

| Feature | Machining Brass | Forming Brass |

|---|---|---|

| Process | Cutting, drilling, turning | Bending, stamping, forging |

| Material Waste | High | Low |

| Surface Finish | Precise and smooth | Varies, may require finishing |

| Complexity | High detail achievable | Limited detail |

| Production Speed | Slower | Faster |

| Cost | Higher per unit | Lower per unit in large runs |

| Typical Applications | Prototyping, custom parts | Mass production, standard parts |

Introduction to Brass: Properties and Applications

Brass, an alloy primarily composed of copper and zinc, is prized for its excellent machinability and corrosion resistance, making it suitable for both machining and forming processes. Machining brass allows for precision components in applications such as electrical connectors, musical instruments, and plumbing fittings, while forming brass exploits its ductility for creating complex shapes used in architectural hardware and decorative elements. Understanding these properties enables optimal selection of manufacturing methods to enhance performance and durability in various industrial and consumer products.

Overview of Brass Machining Processes

Brass machining involves precise cutting techniques such as turning, milling, drilling, and grinding, which allow for intricate component designs with tight tolerances. The material's excellent machinability and low friction properties reduce tool wear and heat generation, enhancing production efficiency. These processes are ideal for producing complex geometries and high-quality surface finishes compared to forming methods commonly used for simpler shapes.

Overview of Brass Forming Techniques

Brass forming techniques include rolling, extrusion, forging, and stamping, allowing the metal to be shaped without removing material. These methods enhance the strength and surface finish of brass components while maintaining dimensional accuracy for applications in plumbing, electrical connectors, and musical instruments. Forming brass enables complex geometries and improved mechanical properties compared to machining, which involves cutting away material and can produce more waste and surface roughness.

Material Suitability: When to Machine vs Form Brass

Brass with medium to high machinability ratings, such as free-machining brass alloys (e.g., C36000), are ideal for machining due to their ease of cutting and ability to achieve precise tolerances. Forming brass, particularly alloys like C26000 (cartridge brass), excels in applications requiring high ductility and deformation without cracking, making it suitable for deep drawing, bending, and stamping processes. Selecting between machining and forming brass depends on alloy composition, desired part geometry, and production volume, with machining favored for complex, low-volume parts and forming preferred for high-volume, simple-shaped components.

Precision and Tolerances in Machining vs Forming Brass

Machining brass offers superior precision and tighter tolerances compared to forming, enabling the production of intricate components with consistent dimensional accuracy often within microns. Forming brass achieves faster production rates but typically results in wider tolerances due to metal flow and spring-back effects, making it less suitable for parts requiring detailed specifications. Industries demanding high-precision parts, such as aerospace and electronics, often prefer machining to achieve exact fits and functional reliability.

Cost Comparison: Machining Brass vs Forming Brass

Machining brass generally incurs higher costs due to material waste and longer production times compared to forming brass, which utilizes processes like stamping or extrusion for more efficient shaping. Forming brass minimizes machining operations, leading to reduced labor and tooling expenses while maintaining material integrity. The cost-benefit of forming becomes more significant in high-volume production runs, whereas machining remains preferable for complex or low-quantity parts despite its higher per-unit cost.

Surface Finish and Quality: Machined vs Formed Brass

Machining brass produces a smooth, precise surface finish with tighter tolerances, ideal for high-quality components requiring fine detail. Forming brass often results in slight surface irregularities and less consistent finishes due to deformation processes, impacting overall surface quality. Machined brass parts also exhibit superior dimensional accuracy compared to formed brass, which is beneficial for applications demanding exact specifications.

Tooling and Equipment Requirements for Brass Machining and Forming

Machining brass requires precision cutting tools made of carbide or high-speed steel to handle its softness and prevent material buildup, along with CNC machines or lathes for intricate shaping. Forming brass demands robust dies and presses capable of applying controlled pressure to achieve desired shapes without cracking, often utilizing hydraulic or mechanical press equipment. Tool wear in machining is minimal due to brass's ductility, whereas forming tools must withstand repeated stress cycles and maintain dimensional accuracy over time.

Environmental Impact: Waste and Energy Usage

Machining brass generates significant metal waste and consumes more energy due to cutting and shaping processes, resulting in higher environmental impact compared to forming. Forming brass, such as forging or rolling, produces less scrap material and generally requires less energy, making it a more sustainable option. Reducing waste and energy consumption in brass manufacturing directly contributes to lowering carbon emissions and conserving raw materials.

Choosing the Right Brass Processing Method for Your Project

Machining brass offers precise dimensional control and is ideal for complex geometries, while forming brass provides efficient shaping for large volumes with minimal waste. Selecting the right brass processing method depends on project requirements such as tolerance levels, production scale, and design complexity. For prototypes and intricate parts, machining brass ensures accuracy; for high-volume manufacturing, forming brass maximizes efficiency and cost-effectiveness.

Machining Brass vs Forming Brass Infographic

materialdif.com

materialdif.com