Leaded brass contains a small percentage of lead to improve machinability and ease of manufacturing, making it ideal for precision components and plumbing fittings. Lead-free brass, on the other hand, complies with environmental and health regulations by eliminating toxic lead content, ensuring safer use in potable water systems and food-related applications. Choosing between leaded and lead-free brass depends on the balance between machining efficiency and regulatory compliance for specific industrial needs.

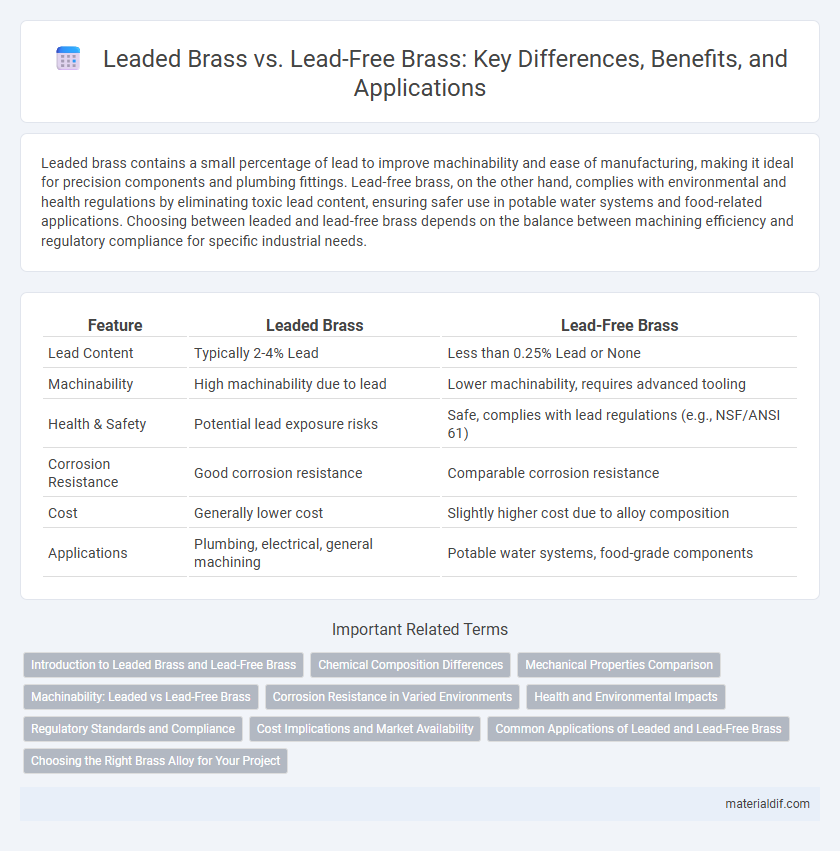

Table of Comparison

| Feature | Leaded Brass | Lead-Free Brass |

|---|---|---|

| Lead Content | Typically 2-4% Lead | Less than 0.25% Lead or None |

| Machinability | High machinability due to lead | Lower machinability, requires advanced tooling |

| Health & Safety | Potential lead exposure risks | Safe, complies with lead regulations (e.g., NSF/ANSI 61) |

| Corrosion Resistance | Good corrosion resistance | Comparable corrosion resistance |

| Cost | Generally lower cost | Slightly higher cost due to alloy composition |

| Applications | Plumbing, electrical, general machining | Potable water systems, food-grade components |

Introduction to Leaded Brass and Lead-Free Brass

Leaded brass contains small amounts of lead, typically around 2-4%, which enhances machinability and improves cutting performance in manufacturing processes. Lead-free brass eliminates lead content to meet environmental regulations and health standards, often using alternatives like bismuth or silicon to maintain similar machinability. Both leaded and lead-free brass are widely used in plumbing, automotive, and electrical applications, balancing compliance with performance requirements.

Chemical Composition Differences

Leaded brass contains approximately 1-3% lead, enhancing machinability and lubricity, while lead-free brass replaces lead with elements such as bismuth or silicon to comply with environmental regulations like RoHS and reduce toxicity. The chemical composition of leaded brass typically includes copper (60-63%), zinc (35-37%), and lead, whereas lead-free variants maintain copper and zinc ratios but substitute lead with safer alloying elements. These compositional differences impact mechanical properties, corrosion resistance, and compliance with health and safety standards in plumbing and electrical applications.

Mechanical Properties Comparison

Leaded brass exhibits superior machinability and ductility due to the presence of lead, which acts as a lubricant during machining, resulting in smoother finishes and reduced tool wear. Lead-free brass offers enhanced corrosion resistance and environmental compliance but generally has lower machinability and slightly reduced tensile strength compared to leaded variants. Mechanical properties such as elongation and yield strength in lead-free brass are optimized through alloying with elements like silicon or bismuth to compensate for the absence of lead.

Machinability: Leaded vs Lead-Free Brass

Leaded brass contains small amounts of lead, which significantly enhances its machinability by reducing tool wear and enabling higher cutting speeds. Lead-free brass, while more environmentally friendly, typically exhibits lower machinability due to the absence of lubricating lead particles, resulting in increased tool wear and slower machining processes. Manufacturers often choose leaded brass for applications requiring precision machining and complex shapes, balancing machinability with regulatory compliance.

Corrosion Resistance in Varied Environments

Leaded brass exhibits enhanced machinability but may suffer from reduced corrosion resistance in harsh environments due to lead inclusions. Lead-free brass, often alloyed with elements like silicon or tin, provides superior corrosion resistance, especially in potable water systems and marine applications. Selecting lead-free brass ensures compliance with environmental regulations and improved durability in varied corrosive conditions.

Health and Environmental Impacts

Leaded brass contains small amounts of lead to improve machinability but poses health risks due to lead exposure, which can cause neurological and developmental issues. Lead-free brass eliminates these health hazards, reducing harmful lead contamination in water systems and minimizing environmental pollution. Switching to lead-free brass supports safer manufacturing processes and aligns with stricter environmental regulations to protect ecosystems and public health.

Regulatory Standards and Compliance

Leaded brass contains trace amounts of lead to improve machinability, but its use is restricted under regulations such as the European Union's REACH and the U.S. Safe Drinking Water Act due to lead's toxicity. Lead-free brass alternatives comply with stringent standards like NSF/ANSI 61 for drinking water systems, ensuring safer usage in potable water applications. Manufacturers prioritize lead-free brass to meet global regulatory requirements and promote environmental and human health safety.

Cost Implications and Market Availability

Leaded brass typically incurs lower production costs due to improved machinability, resulting in reduced manufacturing expenses and competitive pricing in industrial applications. Lead-free brass, mandated by stringent environmental regulations such as the EU's RoHS directive and the US Safe Drinking Water Act, often demands higher alloying costs and advanced processing techniques, which increase overall material prices. Market availability of lead-free brass is expanding rapidly to meet sustainability standards, whereas leaded brass remains prevalent in sectors with less regulatory pressure, influencing procurement strategies and supply chain dynamics.

Common Applications of Leaded and Lead-Free Brass

Leaded brass is widely used in plumbing fittings, electrical connectors, and musical instruments due to its excellent machinability and corrosion resistance. Lead-free brass is preferred in potable water systems, food processing equipment, and medical devices to comply with health and environmental regulations. Both types serve critical roles across industries, balancing performance requirements with safety standards.

Choosing the Right Brass Alloy for Your Project

Leaded brass offers superior machinability and corrosion resistance, making it ideal for precision components and plumbing fixtures. Lead-free brass, compliant with environmental regulations like the Safe Drinking Water Act, provides a safer alternative in applications requiring non-toxic materials, such as potable water systems. Selecting the right brass alloy depends on balancing machinability, regulatory standards, and the specific performance requirements of your project.

Leaded Brass vs Lead-Free Brass Infographic

materialdif.com

materialdif.com