C260 brass, often known as commercial bronze, contains roughly 70% copper and 30% zinc, offering good corrosion resistance and decent machinability, making it ideal for applications like musical instruments and architectural hardware. C360 brass, also called free-machining brass, includes about 61.5% copper, 35.5% zinc, and small amounts of lead, which significantly enhances its machinability for precision parts such as electrical connectors and fittings. While C260 provides better strength and corrosion resistance, C360 excels in machining efficiency and dimensional accuracy for complex components.

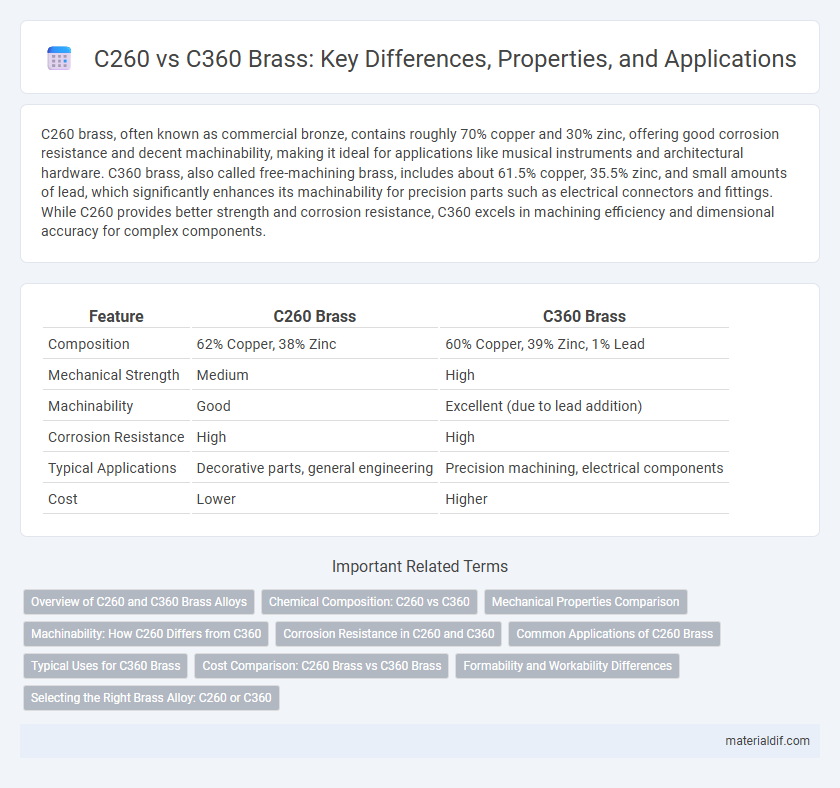

Table of Comparison

| Feature | C260 Brass | C360 Brass |

|---|---|---|

| Composition | 62% Copper, 38% Zinc | 60% Copper, 39% Zinc, 1% Lead |

| Mechanical Strength | Medium | High |

| Machinability | Good | Excellent (due to lead addition) |

| Corrosion Resistance | High | High |

| Typical Applications | Decorative parts, general engineering | Precision machining, electrical components |

| Cost | Lower | Higher |

Overview of C260 and C360 Brass Alloys

C260 brass, also known as cartridge brass, contains approximately 70% copper and 30% zinc, offering excellent corrosion resistance and high ductility, making it ideal for applications like ammunition casings and decorative hardware. C360 brass, or free-machining brass, typically has around 61.5% copper, 35.5% zinc, and small amounts of lead, providing superior machinability and strength for precision components and complex machining processes. Both alloys are widely used in industrial and manufacturing sectors due to their favorable combination of mechanical properties and versatility.

Chemical Composition: C260 vs C360

C260 brass, also known as cartridge brass, typically contains about 70% copper and 30% zinc, offering excellent corrosion resistance and good cold-working properties. In contrast, C360 brass, often called free-machining brass, includes around 61.5% copper, 35.5% zinc, and small amounts of lead (2-3%) to enhance machinability without significantly compromising strength. The main chemical difference lies in the lead content, which makes C360 ideal for precision machining while C260 is favored for forming and deep drawing applications.

Mechanical Properties Comparison

C260 brass, also known as cartridge brass, offers excellent ductility with tensile strength around 55 ksi and good workability, making it ideal for deep drawing applications. In contrast, C360 brass exhibits higher mechanical strength, with tensile strength reaching approximately 70 ksi, and superior machinability attributed to its elevated lead content. Both alloys provide good corrosion resistance, but C360's enhanced mechanical properties suit precision machining and components requiring greater durability.

Machinability: How C260 Differs from C360

C260 brass features lower lead content compared to C360, resulting in reduced machinability but improved surface finish and increased strength. C360 brass contains about 2% lead, enhancing its machinability and allowing for faster cutting speeds and longer tool life. Manufacturers often choose C360 for complex machining applications requiring high precision and efficiency, while C260 is preferred when corrosion resistance and durability are prioritized over ease of machining.

Corrosion Resistance in C260 and C360

C260 brass, composed mainly of copper and zinc with minimal lead content, offers superior corrosion resistance in applications exposed to moisture and mild chemicals. In contrast, C360 brass contains higher lead content, enhancing machinability but slightly reducing its resistance to corrosive environments. Selecting C260 ensures better durability and longevity in marine or outdoor conditions where corrosion resistance is critical.

Common Applications of C260 Brass

C260 brass, known for its excellent cold working properties and high strength, is commonly used in electrical connectors, plumbing fittings, and musical instruments, where precision and corrosion resistance are critical. Its superior machinability compared to C360 makes it ideal for manufacturing intricate components like fasteners and valves. While C360 is often favored for high machinability in complex shapes, C260's durability and reliable mechanical performance dominate applications requiring toughness and moderate formability.

Typical Uses for C360 Brass

C360 brass, also known as free-machining brass, is highly favored for machining-intensive applications due to its excellent machinability, making it ideal for precision components such as fittings, valves, and gears. Its high copper content combined with lead additions ensures smooth cutting and minimal tool wear, which is essential in manufacturing processes requiring tight tolerances. Compared to C260 brass, which is commonly used for decorative and electrical applications, C360 excels in mechanical performance where complex shapes and detailed features are necessary.

Cost Comparison: C260 Brass vs C360 Brass

C260 brass generally costs less than C360 brass due to its lower copper content and simpler manufacturing process. C360 brass offers higher machinability and strength, which can justify its elevated price in precision applications. Selecting between C260 and C360 brass depends on balancing budget constraints with performance requirements in specific industrial uses.

Formability and Workability Differences

C360 brass offers superior formability and workability compared to C260 due to its higher copper content and added lead, which enhances machinability and allows for more intricate shaping without cracking. C260, also known as cartridge brass, has less lead content, making it less suitable for complex forming processes but still adequate for general applications requiring moderate ductility. The improved machinability of C360 makes it the preferred choice for precision parts and components requiring tight tolerances and extensive machining operations.

Selecting the Right Brass Alloy: C260 or C360

C260 brass offers excellent machinability with decent strength, making it ideal for general engineering applications and decorative components. C360 brass provides superior machinability and higher strength, suited for precision parts requiring fine detailing and durability. Selecting between C260 and C360 depends on the balance of machinability, strength, and application-specific requirements in brass alloy performance.

C260 vs C360 Infographic

materialdif.com

materialdif.com