Free machining brass contains additives such as lead or bismuth to improve its machinability, resulting in faster cutting speeds, better surface finish, and reduced tool wear compared to standard brass. Standard brass offers superior corrosion resistance and strength but is more challenging to machine, often causing higher production costs and longer manufacturing times. Choosing between free machining and standard brass depends on the balance between ease of machining and mechanical properties required for the specific application.

Table of Comparison

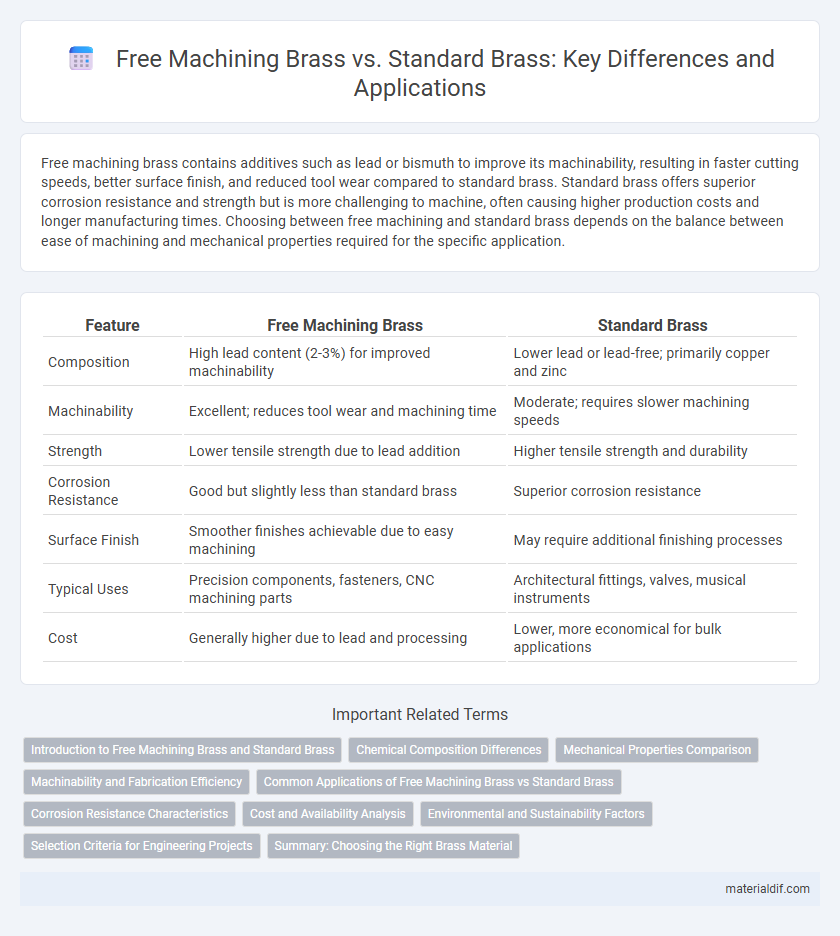

| Feature | Free Machining Brass | Standard Brass |

|---|---|---|

| Composition | High lead content (2-3%) for improved machinability | Lower lead or lead-free; primarily copper and zinc |

| Machinability | Excellent; reduces tool wear and machining time | Moderate; requires slower machining speeds |

| Strength | Lower tensile strength due to lead addition | Higher tensile strength and durability |

| Corrosion Resistance | Good but slightly less than standard brass | Superior corrosion resistance |

| Surface Finish | Smoother finishes achievable due to easy machining | May require additional finishing processes |

| Typical Uses | Precision components, fasteners, CNC machining parts | Architectural fittings, valves, musical instruments |

| Cost | Generally higher due to lead and processing | Lower, more economical for bulk applications |

Introduction to Free Machining Brass and Standard Brass

Free machining brass contains lead or other additives to improve machinability, allowing faster, smoother cutting and reduced tool wear compared to standard brass. Standard brass primarily consists of copper and zinc, offering good corrosion resistance and strength but less efficient machinability. Both types are widely used in manufacturing, with free machining brass favored for complex, high-volume machining processes.

Chemical Composition Differences

Free machining brass contains higher amounts of lead, typically around 2.5-3.5%, which enhances its machinability by reducing tool wear and improving chip formation, compared to standard brass that has minimal or no lead content. Standard brass primarily consists of copper (60-70%) and zinc (30-40%) with trace elements, promoting corrosion resistance and strength but lower machinability. The lead in free machining brass does not significantly compromise its corrosion resistance, making it ideal for precision components requiring efficient manufacturing.

Mechanical Properties Comparison

Free machining brass exhibits superior machinability due to its lead content, which reduces tool wear and improves cutting speed compared to standard brass. Mechanical properties show that free machining brass generally has slightly lower tensile strength and hardness but maintains adequate ductility for most machining applications. Standard brass offers higher strength and hardness, making it more suitable for structural components requiring greater mechanical durability.

Machinability and Fabrication Efficiency

Free machining brass, characterized by higher lead content around 2-3%, offers superior machinability compared to standard brass, which typically contains less than 1% lead. The increased lead content reduces tool wear and enhances cutting speed, resulting in higher fabrication efficiency and lower production costs. Standard brass provides better mechanical strength and corrosion resistance but requires slower machining processes, making free machining brass preferable for high-volume manufacturing where speed and tool longevity are critical.

Common Applications of Free Machining Brass vs Standard Brass

Free machining brass is widely used in precision components such as electrical connectors, gears, and fasteners due to its excellent machinability and reduced tool wear. Standard brass is commonly applied in plumbing fittings, architectural hardware, and musical instruments where higher strength and corrosion resistance are essential. Both alloys serve distinct industrial roles, optimizing performance based on machining efficiency and mechanical properties.

Corrosion Resistance Characteristics

Free machining brass typically contains higher lead content, which can slightly reduce its corrosion resistance compared to standard brass alloys. Standard brass, often composed of copper and zinc with minimal alloying elements, exhibits superior resistance to corrosion in various environments due to its more uniform microstructure. The enhanced corrosion resistance of standard brass makes it preferable for applications exposed to moisture and harsh chemicals.

Cost and Availability Analysis

Free Machining Brass offers superior machinability due to its lead content, resulting in reduced cutting time and tooling wear, which lowers manufacturing costs despite higher raw material prices. Standard Brass, typically lead-free or containing minimal lead, is more widely available and less expensive per pound but incurs higher processing costs due to slower machining speeds and increased tool replacement. The overall cost-effectiveness depends heavily on production volume, with Free Machining Brass favored for high-volume machining requiring precision and efficiency.

Environmental and Sustainability Factors

Free machining brass contains lead, which enhances machinability but raises environmental concerns due to lead toxicity and disposal challenges. Standard brass, typically lead-free or with lower lead content, offers better sustainability by reducing harmful emissions and facilitating recycling processes. Choosing standard brass supports eco-friendly manufacturing and aligns with stricter environmental regulations targeting heavy metal use.

Selection Criteria for Engineering Projects

Free machining brass offers superior machinability due to its higher lead content, reducing tool wear and improving production speed, making it ideal for complex engineering projects requiring precision. Standard brass, with lower lead content, provides better corrosion resistance and mechanical strength, which benefits applications exposed to harsh environments or high stress. Engineers should evaluate machining efficiency versus durability requirements when selecting between free machining brass and standard brass for optimal project outcomes.

Summary: Choosing the Right Brass Material

Free machining brass contains lead to improve machinability, reducing tool wear and increasing production speed, making it ideal for complex, high-volume manufacturing processes. Standard brass lacks lead additives but offers superior corrosion resistance and mechanical strength, suitable for applications requiring durability and longer service life. Selecting the right brass material depends on balancing machinability with performance requirements for specific industrial or commercial uses.

Free Machining Brass vs Standard Brass Infographic

materialdif.com

materialdif.com