Free-cutting brass contains added elements such as lead to enhance machinability, allowing for faster and more precise manufacturing processes compared to standard brass. Standard brass, composed primarily of copper and zinc, offers superior strength and corrosion resistance but may require slower machining speeds and more tool wear. Selecting free-cutting brass improves production efficiency in detailed components, while standard brass is preferred for applications demanding greater durability and aesthetic quality.

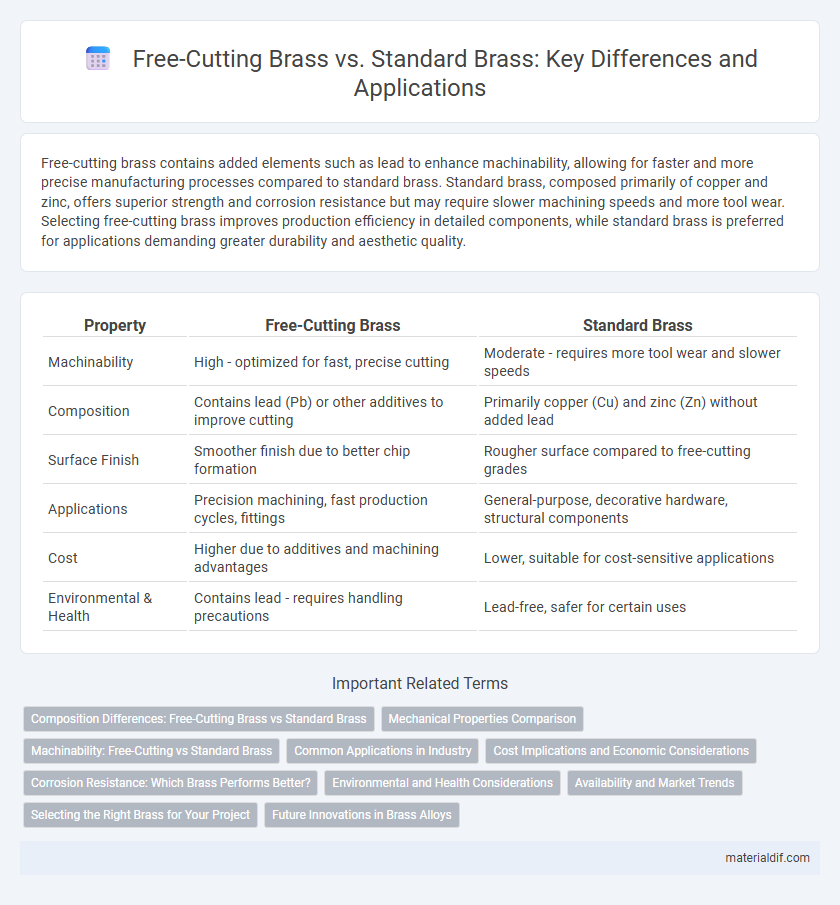

Table of Comparison

| Property | Free-Cutting Brass | Standard Brass |

|---|---|---|

| Machinability | High - optimized for fast, precise cutting | Moderate - requires more tool wear and slower speeds |

| Composition | Contains lead (Pb) or other additives to improve cutting | Primarily copper (Cu) and zinc (Zn) without added lead |

| Surface Finish | Smoother finish due to better chip formation | Rougher surface compared to free-cutting grades |

| Applications | Precision machining, fast production cycles, fittings | General-purpose, decorative hardware, structural components |

| Cost | Higher due to additives and machining advantages | Lower, suitable for cost-sensitive applications |

| Environmental & Health | Contains lead - requires handling precautions | Lead-free, safer for certain uses |

Composition Differences: Free-Cutting Brass vs Standard Brass

Free-cutting brass contains a higher concentration of lead, typically around 2.5-3.5%, which enhances machinability and reduces tool wear compared to standard brass, which usually has minimal or no lead content. Standard brass primarily consists of copper and zinc in varying proportions, such as 60-70% copper and 30-40% zinc, offering greater strength and corrosion resistance but lower machinability. The addition of lead in free-cutting brass improves its ease of machining without significantly compromising physical properties, making it ideal for precision components requiring intricate shapes.

Mechanical Properties Comparison

Free-cutting brass exhibits higher machinability due to elevated sulfur or lead content, resulting in improved chip formation and reduced cutting forces compared to standard brass. Standard brass typically offers superior tensile strength and corrosion resistance but compromises on ease of machining. Mechanical properties such as yield strength, hardness, and elongation in free-cutting brass are optimized for efficient manufacturing processes, whereas standard brass prioritizes structural durability and long-term performance.

Machinability: Free-Cutting vs Standard Brass

Free-cutting brass contains additives like lead or bismuth that significantly enhance its machinability by reducing tool wear and allowing faster cutting speeds compared to standard brass. Standard brass, typically composed of copper and zinc, offers lower machinability, requiring slower machining processes and increased tool maintenance. The improved machinability of free-cutting brass makes it ideal for high-volume production environments requiring precise, efficient component fabrication.

Common Applications in Industry

Free-cutting brass is widely used in precision machining industries due to its excellent machinability, making it ideal for producing small, intricate components such as screws, fittings, and gears. Standard brass, known for its strength and corrosion resistance, finds common applications in plumbing, electrical connectors, and decorative hardware. Industrial sectors often choose free-cutting brass for high-volume, automated manufacturing, while standard brass is preferred where durability and mechanical performance are critical.

Cost Implications and Economic Considerations

Free-cutting brass typically commands higher prices than standard brass due to the inclusion of lead, which enhances machinability and reduces manufacturing time and tool wear. These cost savings in production offset the initial material expense, making free-cutting brass economically advantageous for high-volume machining processes. Standard brass, while less costly upfront, may incur greater machining costs and longer production cycles, impacting overall project budgets.

Corrosion Resistance: Which Brass Performs Better?

Free-cutting brass contains additives like lead that improve machinability but can reduce corrosion resistance compared to standard brass, which typically has a higher copper content contributing to better resistance against corrosion. Standard brass alloys such as C260 (cartridge brass) offer superior protection in marine or humid environments due to their enhanced durability against oxidation and pitting. For applications requiring both machinability and moderate corrosion resistance, free-cutting brass is suitable, but for long-term exposure to corrosive elements, standard brass outperforms free-cutting variants.

Environmental and Health Considerations

Free-cutting brass, which contains higher lead content to improve machinability, poses greater environmental and health risks due to lead's toxicity and potential for contamination during manufacturing and disposal. Standard brass, with lower lead levels, offers a safer alternative, reducing hazardous emissions and exposure risks in industrial and consumer applications. Selecting standard brass over free-cutting varieties supports compliance with environmental regulations and promotes occupational health safety.

Availability and Market Trends

Free-cutting brass is widely available in various grades such as C360 and C377, favored in manufacturing for its superior machinability and reduced tool wear, driving increased demand in precision engineering sectors. Standard brass, including common alloys like C260 and C270, maintains steady market presence due to its versatility and cost-effectiveness in general applications. Recent market trends indicate a growing preference for free-cutting brass in automotive and electronics industries, supported by advancements in alloy compositions enhancing performance and supply chain availability.

Selecting the Right Brass for Your Project

Free-cutting brass contains small amounts of lead, enhancing machinability and allowing for faster, cleaner cuts with reduced tool wear, making it ideal for complex machining and high-volume production. Standard brass, typically composed of copper and zinc without lead, offers superior corrosion resistance and strength, better suited for structural components and applications requiring durability. Selecting the right brass depends on balancing machinability needs with mechanical properties and environmental exposure to ensure optimal performance and cost-efficiency.

Future Innovations in Brass Alloys

Free-cutting brass, characterized by its lead content enhancing machinability, is evolving with eco-friendly alternatives like bismuth and silicon to meet environmental regulations. Future innovations in brass alloys emphasize improved sustainability, combining high machinability with reduced toxicity and enhanced corrosion resistance. Advances in additive manufacturing and alloy design are driving the development of smart, high-performance brass alloys tailored for aerospace, automotive, and electronics industries.

Free-Cutting Brass vs Standard Brass Infographic

materialdif.com

materialdif.com