Sheet brass offers a flat, uniform surface ideal for detailed engraving and precise metalwork, while extruded brass provides enhanced structural integrity with its solid, continuous cross-sections suitable for crafting robust components. Sheet brass is typically thinner and easier to cut into complex shapes, making it perfect for decorative applications, whereas extruded brass's durability supports mechanical and load-bearing uses. Choosing between sheet and extruded brass depends on whether flexibility in design or strength in function is prioritized.

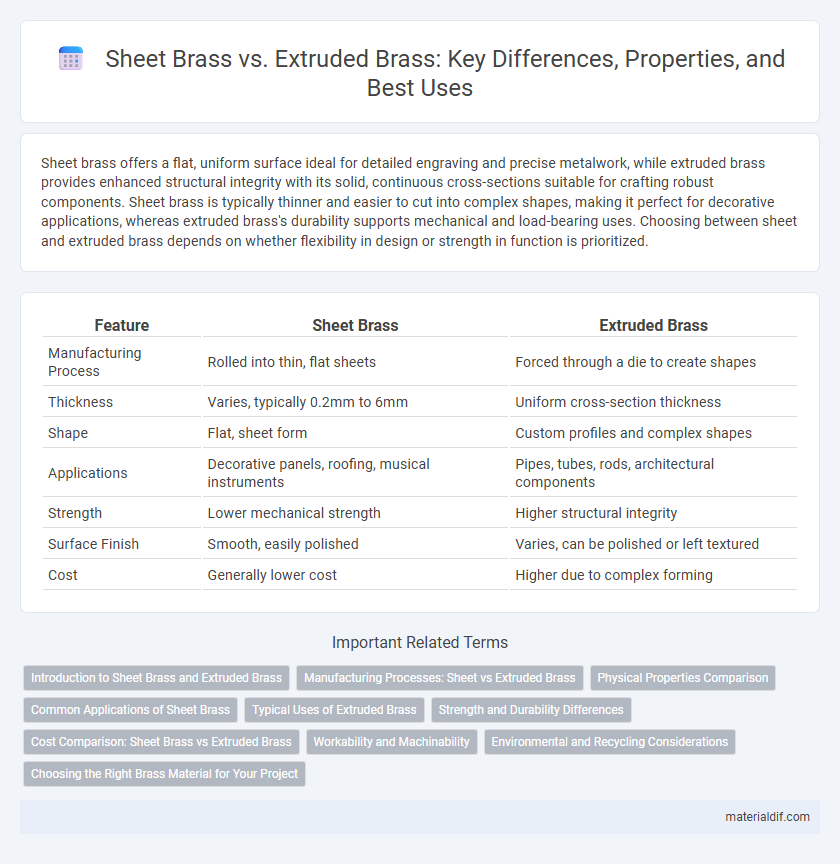

Table of Comparison

| Feature | Sheet Brass | Extruded Brass |

|---|---|---|

| Manufacturing Process | Rolled into thin, flat sheets | Forced through a die to create shapes |

| Thickness | Varies, typically 0.2mm to 6mm | Uniform cross-section thickness |

| Shape | Flat, sheet form | Custom profiles and complex shapes |

| Applications | Decorative panels, roofing, musical instruments | Pipes, tubes, rods, architectural components |

| Strength | Lower mechanical strength | Higher structural integrity |

| Surface Finish | Smooth, easily polished | Varies, can be polished or left textured |

| Cost | Generally lower cost | Higher due to complex forming |

Introduction to Sheet Brass and Extruded Brass

Sheet brass consists of flat, thin metal layers created by rolling brass ingots, offering excellent malleability and uniform thickness for applications like decorative panels and musical instruments. Extruded brass is produced by forcing heated brass billets through a shaped die, resulting in continuous profiles with precise cross-sections ideal for architectural components and mechanical parts. Understanding the distinct manufacturing processes helps determine the best material choice based on required strength, flexibility, and design complexity.

Manufacturing Processes: Sheet vs Extruded Brass

Sheet brass is produced through a hot-rolling process where brass billets are flattened into thin, uniform sheets, allowing for precise thickness control and smooth surface finishes ideal for stamping and forming applications. Extruded brass is manufactured by forcing heated brass billets through a die to create continuous profiles with a consistent cross-sectional shape, enabling complex geometries and higher strength due to grain flow alignment. The choice between sheet and extruded brass manufacturing depends on application requirements, with sheet brass favored for flat parts and extruded brass suited for custom shapes like tubing and rods.

Physical Properties Comparison

Sheet brass exhibits uniform thickness and smooth surfaces, making it ideal for applications requiring precision and malleability, while extruded brass offers enhanced strength and dimensional consistency due to the extrusion process. The physical properties of sheet brass include high ductility and good corrosion resistance, whereas extruded brass provides superior tensile strength and improved hardness. Both types maintain excellent electrical conductivity, but the choice depends on whether flexibility or mechanical strength is prioritized in the project's requirements.

Common Applications of Sheet Brass

Sheet brass is widely used in architectural applications such as decorative panels, wall cladding, and signage due to its malleability and bright finish. It is also common in musical instruments, electrical components, and jewelry where precise shaping and aesthetic appeal are critical. Sheet brass offers excellent machinability and corrosion resistance, making it ideal for both functional and ornamental purposes.

Typical Uses of Extruded Brass

Extruded brass is commonly used in applications requiring high strength and corrosion resistance, such as plumbing fittings, electrical connectors, and architectural hardware. Its uniformity and durability make it ideal for precision machined components and intricate shapes in mechanical parts and automotive industries. Sheet brass, by comparison, is more suited for decorative applications, embossing, and crafting where flat, thin material is essential.

Strength and Durability Differences

Sheet brass exhibits excellent strength in thin, flat forms, making it ideal for decorative and structural applications where flexibility is essential. Extruded brass demonstrates superior durability and mechanical strength due to its continuous grain structure, which enhances resistance to impact and wear in demanding environments. The choice between sheet and extruded brass depends on the balance required between tensile strength, formability, and long-term material resilience.

Cost Comparison: Sheet Brass vs Extruded Brass

Sheet brass typically costs less per pound than extruded brass due to lower production complexity, making it a more budget-friendly option for large surface area applications. Extruded brass, shaped through a detailed forging process, commands higher prices but offers enhanced mechanical strength and dimensional accuracy. For projects prioritizing cost efficiency over intricate shapes, sheet brass presents the more economical material choice.

Workability and Machinability

Sheet brass offers excellent workability due to its thin, flat form, making it ideal for bending, cutting, and forming into complex shapes with precision. Extruded brass, characterized by its uniform cross-sectional profiles, provides superior machinability for applications requiring intricate detailing and tight tolerances. Both types exhibit good machinability, but sheet brass is preferred for stamping and fabrication, while extruded brass excels in CNC machining and extrusion-based manufacturing processes.

Environmental and Recycling Considerations

Sheet brass and extruded brass differ significantly in their environmental impact and recyclability; sheet brass production typically generates less waste due to its flat form and easier cutting processes, while extruded brass can result in more scrap material from shaping and trimming. Both types of brass are highly recyclable, with copper and zinc alloys recovering up to 90% of their material value during recycling, contributing to lower carbon emissions compared to primary metal extraction. Choosing recycled brass materials, whether sheet or extruded, supports circular economy practices and reduces the overall environmental footprint in manufacturing and construction.

Choosing the Right Brass Material for Your Project

Sheet brass offers excellent machinability and uniform thickness, making it ideal for applications requiring precise shaping and cutting, such as decorative panels and architectural details. Extruded brass provides superior strength and durability, suitable for structural components and mechanical parts that demand high tensile strength and impact resistance. Selecting between sheet and extruded brass depends on project requirements like flexibility, strength, and fabrication complexity to ensure optimal performance and cost efficiency.

Sheet Brass vs Extruded Brass Infographic

materialdif.com

materialdif.com