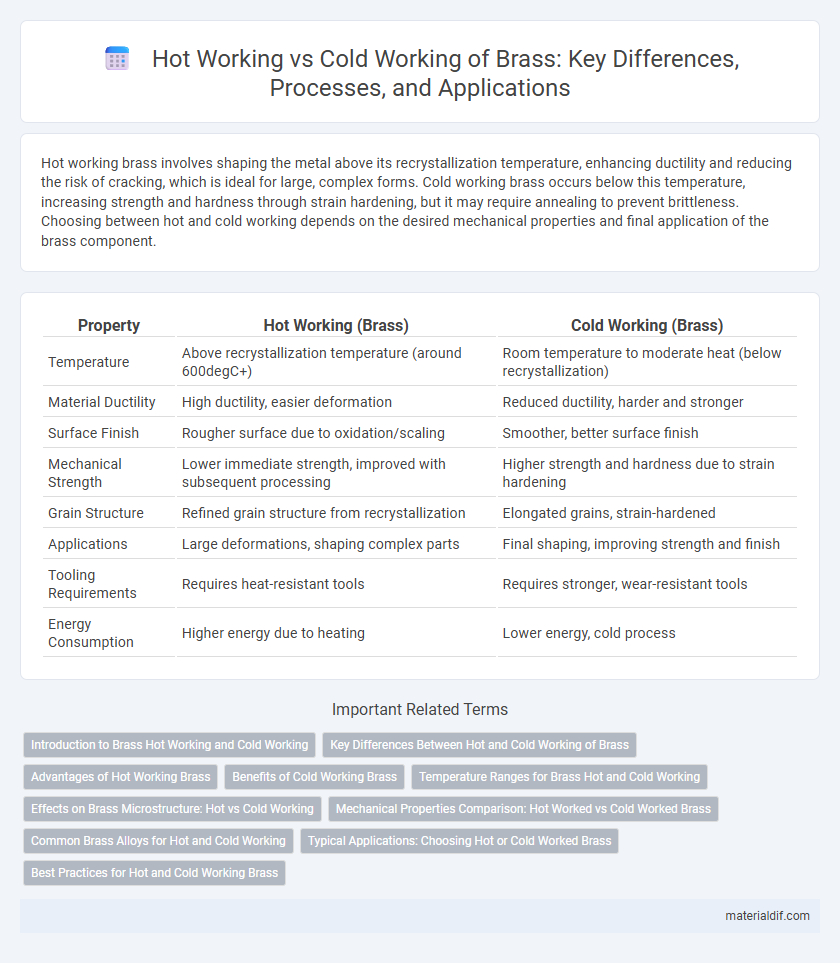

Hot working brass involves shaping the metal above its recrystallization temperature, enhancing ductility and reducing the risk of cracking, which is ideal for large, complex forms. Cold working brass occurs below this temperature, increasing strength and hardness through strain hardening, but it may require annealing to prevent brittleness. Choosing between hot and cold working depends on the desired mechanical properties and final application of the brass component.

Table of Comparison

| Property | Hot Working (Brass) | Cold Working (Brass) |

|---|---|---|

| Temperature | Above recrystallization temperature (around 600degC+) | Room temperature to moderate heat (below recrystallization) |

| Material Ductility | High ductility, easier deformation | Reduced ductility, harder and stronger |

| Surface Finish | Rougher surface due to oxidation/scaling | Smoother, better surface finish |

| Mechanical Strength | Lower immediate strength, improved with subsequent processing | Higher strength and hardness due to strain hardening |

| Grain Structure | Refined grain structure from recrystallization | Elongated grains, strain-hardened |

| Applications | Large deformations, shaping complex parts | Final shaping, improving strength and finish |

| Tooling Requirements | Requires heat-resistant tools | Requires stronger, wear-resistant tools |

| Energy Consumption | Higher energy due to heating | Lower energy, cold process |

Introduction to Brass Hot Working and Cold Working

Brass hot working involves deforming the alloy at elevated temperatures, typically above 450degC, enhancing its ductility and reducing the risk of cracking during processes like forging, extrusion, and rolling. Cold working brass occurs at room temperature, increasing strength and hardness through strain hardening while maintaining a smooth surface finish, commonly used in drawing, bending, and stamping. Understanding the temperature-dependent mechanical properties of brass is essential for optimizing manufacturing methods and achieving desired performance characteristics.

Key Differences Between Hot and Cold Working of Brass

Hot working of brass involves deforming the metal above its recrystallization temperature, resulting in improved ductility and reduced strain hardening, which allows extensive shaping without cracking. Cold working occurs below the recrystallization temperature, increasing the strength and hardness of brass through strain hardening but reducing its ductility. Key differences include temperature range, mechanical properties enhancement, and microstructural changes, with hot working promoting grain refinement and cold working leading to increased dislocation density.

Advantages of Hot Working Brass

Hot working brass enhances ductility and allows for significant deformation without cracking, improving the overall malleability of the alloy. This process refines the grain structure, resulting in improved mechanical properties such as increased strength and toughness. Hot working also reduces the occurrence of residual stresses, making the brass more suitable for subsequent machining and forming operations.

Benefits of Cold Working Brass

Cold working brass enhances its mechanical strength and hardness through strain hardening without the need for high-temperature processing. This process improves surface finish and dimensional accuracy, making it ideal for precision components. Additionally, cold worked brass exhibits improved corrosion resistance and retains better electrical conductivity compared to hot worked brass.

Temperature Ranges for Brass Hot and Cold Working

Brass hot working typically occurs within the temperature range of 700degC to 900degC, enabling enhanced ductility and reduced deformation resistance. Cold working of brass is performed at or near room temperature, usually below 200degC, resulting in increased strength and hardness due to strain hardening. Controlling these temperature ranges is crucial for optimizing mechanical properties and minimizing defects during brass forming processes.

Effects on Brass Microstructure: Hot vs Cold Working

Hot working brass involves deformation above recrystallization temperature, resulting in refined grain structure and enhanced ductility due to dynamic recrystallization. Cold working brass occurs below recrystallization temperature, causing strain hardening, increased dislocation density, and elongated grains, which improves strength but reduces ductility. The contrasting microstructural effects determine the mechanical properties and suitability of brass for various applications.

Mechanical Properties Comparison: Hot Worked vs Cold Worked Brass

Hot worked brass exhibits enhanced ductility and reduced strength due to recrystallization at elevated temperatures, making it ideal for intricate forming processes. Cold worked brass achieves higher tensile strength and hardness through strain hardening but sacrifices some ductility and toughness. The choice between hot and cold working depends on the desired balance of mechanical properties such as yield strength, elongation, and impact resistance for specific applications.

Common Brass Alloys for Hot and Cold Working

Common brass alloys suitable for hot working include Alpha and Alpha-Beta brasses, known for their excellent ductility and workability at elevated temperatures. Cold working typically employs Alpha brasses such as cartridge brass (70/30 Cu/Zn) and commercial bronze (90/10 Cu/Sn), which exhibit high strength and improved surface finish without the need for reheating. Understanding the phase composition and alloying elements is crucial for optimizing mechanical properties and minimizing defects during manufacturing processes.

Typical Applications: Choosing Hot or Cold Worked Brass

Hot worked brass is commonly utilized in applications requiring extensive deformation, such as automotive components and architectural fittings, due to its improved ductility and reduced internal stresses. Cold worked brass, favored in electrical connectors and precision instruments, offers enhanced strength, surface finish, and dimensional accuracy. Selecting between hot and cold worked brass depends on balancing mechanical properties with manufacturing precision for the specific application.

Best Practices for Hot and Cold Working Brass

Hot working brass involves heating the alloy above its recrystallization temperature, typically between 650degC and 900degC, to improve ductility and reduce work hardening, making it easier to shape complex components. Cold working brass requires careful control of strain rates and incremental deformation to avoid cracking, as the alloy becomes harder and stronger but less ductile at room temperature. Best practices include preheating before hot working to prevent oxidation and annealing after cold working to restore ductility and relieve internal stresses.

Hot Working vs Cold Working (Brass) Infographic

materialdif.com

materialdif.com