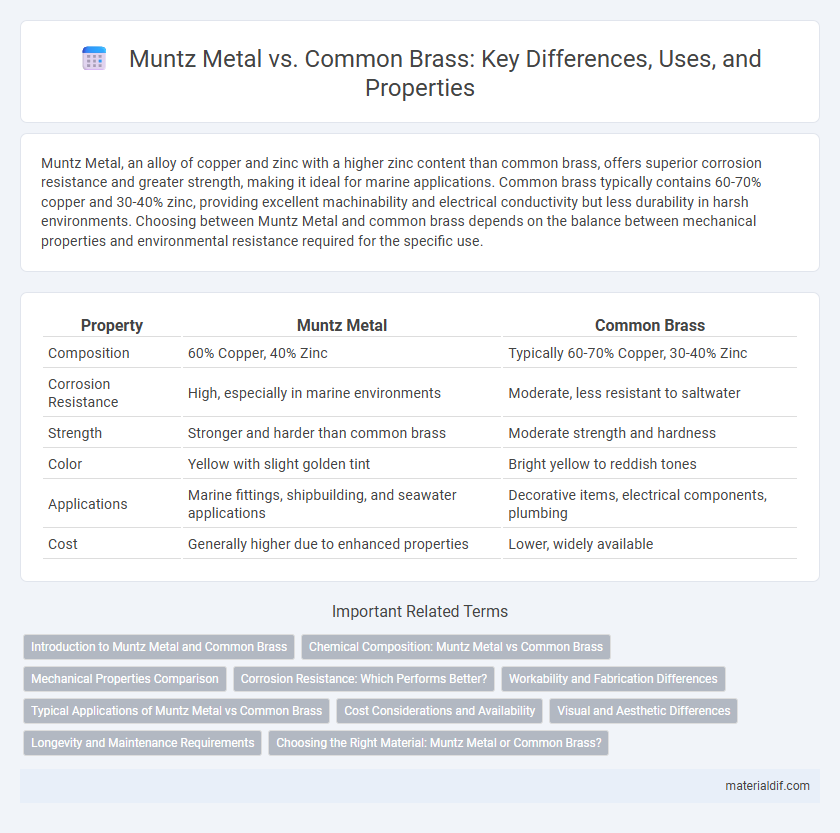

Muntz Metal, an alloy of copper and zinc with a higher zinc content than common brass, offers superior corrosion resistance and greater strength, making it ideal for marine applications. Common brass typically contains 60-70% copper and 30-40% zinc, providing excellent machinability and electrical conductivity but less durability in harsh environments. Choosing between Muntz Metal and common brass depends on the balance between mechanical properties and environmental resistance required for the specific use.

Table of Comparison

| Property | Muntz Metal | Common Brass |

|---|---|---|

| Composition | 60% Copper, 40% Zinc | Typically 60-70% Copper, 30-40% Zinc |

| Corrosion Resistance | High, especially in marine environments | Moderate, less resistant to saltwater |

| Strength | Stronger and harder than common brass | Moderate strength and hardness |

| Color | Yellow with slight golden tint | Bright yellow to reddish tones |

| Applications | Marine fittings, shipbuilding, and seawater applications | Decorative items, electrical components, plumbing |

| Cost | Generally higher due to enhanced properties | Lower, widely available |

Introduction to Muntz Metal and Common Brass

Muntz Metal, an alloy composed primarily of 60% copper and 40% zinc with a small amount of iron, offers superior corrosion resistance compared to common brass, which typically contains 70% copper and 30% zinc. While common brass is widely used for decorative and mechanical purposes due to its malleability and aesthetic appeal, Muntz Metal excels in marine environments because of its enhanced strength and resistance to seawater corrosion. The specific composition and properties of Muntz Metal make it a preferred choice for applications like ship hulls and underwater fittings where durability against harsh conditions is critical.

Chemical Composition: Muntz Metal vs Common Brass

Muntz Metal typically consists of approximately 60% copper and 40% zinc, with small amounts of iron and manganese that enhance its strength and corrosion resistance. Common brass, by contrast, usually contains 55-95% copper and 5-45% zinc, with variations in zinc content affecting its malleability and color. The higher zinc content in Muntz Metal makes it more durable and suited for marine applications compared to standard brass alloys.

Mechanical Properties Comparison

Muntz Metal, an alloy composed of approximately 60% copper and 40% zinc with a small amount of iron, offers superior tensile strength and corrosion resistance compared to common brass, which typically contains 67-85% copper and 15-33% zinc. Muntz Metal exhibits a tensile strength of around 350 MPa and higher hardness, making it ideal for marine applications where mechanical durability is critical. In contrast, common brass has a tensile strength ranging between 200-400 MPa, but generally lower corrosion resistance and mechanical performance under stress conditions.

Corrosion Resistance: Which Performs Better?

Muntz metal, an alloy containing approximately 60% copper and 40% zinc, demonstrates superior corrosion resistance compared to common brass, which typically has a lower copper content and higher zinc concentration. The higher copper ratio in Muntz metal enhances its ability to withstand marine and industrial environments, reducing the risk of dezincification and rust formation. Common brass, while versatile, is more susceptible to corrosion in humid or saline conditions, making Muntz metal the preferred choice for applications requiring long-term durability against corrosion.

Workability and Fabrication Differences

Muntz Metal, an alloy composed of approximately 60% copper and 40% zinc, exhibits higher strength and corrosion resistance compared to common brass, which typically contains 67% copper and 33% zinc. The increased zinc content in Muntz Metal results in a tougher material that is less malleable, requiring more force during cutting, machining, and forming processes. Common brass offers superior workability due to its lower zinc content, making it easier to shape, bend, and fabricate for intricate applications.

Typical Applications of Muntz Metal vs Common Brass

Muntz Metal, an alloy of approximately 60% copper and 40% zinc with small amounts of iron, is primarily used in marine applications such as ship hulls, propellers, and underwater fittings due to its superior corrosion resistance in seawater. Common Brass, typically consisting of about 67% copper and 33% zinc, finds widespread use in architectural fittings, musical instruments, and decorative items where machinability and aesthetic appeal are prioritized. The distinct composition of Muntz Metal makes it ideal for heavy-duty, corrosion-resistant environments, while common brass is favored for everyday applications requiring moderate strength and good workability.

Cost Considerations and Availability

Muntz Metal, an alloy of approximately 60% copper and 40% zinc, is generally more cost-effective than common brass due to its lower copper content, resulting in reduced material expenses. Its widespread availability and higher strength make it a preferred choice for marine and industrial applications, where durability and resistance to corrosion are critical. Common brass, with varied copper and zinc ratios, tends to have higher raw material costs and limited availability in certain compositions, which can impact project budgets and lead times.

Visual and Aesthetic Differences

Muntz Metal exhibits a distinct yellowish-golden hue with a slightly reddish tint due to its higher copper content, offering a richer and warmer appearance compared to common brass. Common brass typically has a lighter, more uniform yellow color that appears brighter and less intense. Over time, Muntz Metal develops a deeper patina, enhancing its antique aesthetic, while common brass tends to maintain a shinier, polished look with less pronounced aging.

Longevity and Maintenance Requirements

Muntz Metal, an alloy containing approximately 60% copper and 40% zinc with a small amount of iron, offers superior corrosion resistance compared to common brass, extending its longevity in harsh marine and industrial environments. Its higher copper content and specific alloy composition reduce oxidation and tarnishing, resulting in lower maintenance requirements and longer service life. In contrast, common brass, typically with a zinc content of 30-40%, requires more frequent cleaning and protection to prevent degradation and maintain appearance.

Choosing the Right Material: Muntz Metal or Common Brass?

Muntz Metal, an alloy composed of approximately 60% copper and 40% zinc with trace amounts of iron, offers superior corrosion resistance and higher strength compared to common brass, which typically contains around 70% copper and 30% zinc. Choosing Muntz Metal is ideal for marine applications and outdoor environments due to its enhanced durability and resistance to dezincification, while common brass is preferred for decorative uses and electrical components because of its excellent machinability and conductivity. Evaluating project requirements such as environmental exposure, mechanical strength, and aesthetic preferences is crucial in selecting between Muntz Metal and common brass.

Muntz Metal vs Common Brass Infographic

materialdif.com

materialdif.com