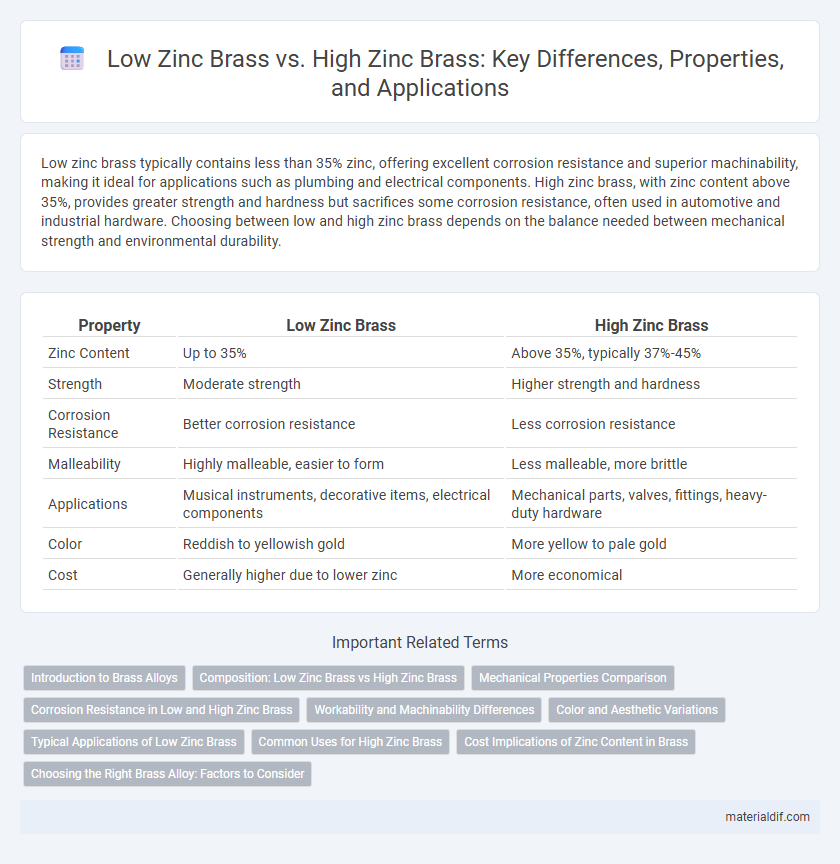

Low zinc brass typically contains less than 35% zinc, offering excellent corrosion resistance and superior machinability, making it ideal for applications such as plumbing and electrical components. High zinc brass, with zinc content above 35%, provides greater strength and hardness but sacrifices some corrosion resistance, often used in automotive and industrial hardware. Choosing between low and high zinc brass depends on the balance needed between mechanical strength and environmental durability.

Table of Comparison

| Property | Low Zinc Brass | High Zinc Brass |

|---|---|---|

| Zinc Content | Up to 35% | Above 35%, typically 37%-45% |

| Strength | Moderate strength | Higher strength and hardness |

| Corrosion Resistance | Better corrosion resistance | Less corrosion resistance |

| Malleability | Highly malleable, easier to form | Less malleable, more brittle |

| Applications | Musical instruments, decorative items, electrical components | Mechanical parts, valves, fittings, heavy-duty hardware |

| Color | Reddish to yellowish gold | More yellow to pale gold |

| Cost | Generally higher due to lower zinc | More economical |

Introduction to Brass Alloys

Brass alloys are primarily composed of copper and zinc, with the zinc content determining whether the alloy is classified as low zinc brass or high zinc brass. Low zinc brass typically contains less than 35% zinc, offering enhanced corrosion resistance and excellent machinability, making it ideal for decorative and electrical applications. High zinc brass, with zinc content exceeding 35%, provides greater strength and hardness, suited for mechanical components and industrial uses.

Composition: Low Zinc Brass vs High Zinc Brass

Low zinc brass typically contains up to 35% zinc, providing enhanced machinability and corrosion resistance, which is ideal for precision components. High zinc brass contains zinc levels above 35% and can reach up to 45%, offering increased strength and hardness but reduced ductility compared to low zinc brass. The compositional difference directly impacts mechanical properties, making low zinc brass suitable for decorative and electrical applications, while high zinc brass is preferred in heavy-duty industrial uses.

Mechanical Properties Comparison

Low zinc brass typically contains less than 20% zinc, resulting in higher ductility and better corrosion resistance, making it ideal for applications requiring formability and durability. High zinc brass, with zinc content above 20%, exhibits greater strength and hardness but reduced malleability and corrosion resistance, suited for structural components under mechanical stress. The mechanical properties such as tensile strength, yield strength, and hardness increase with higher zinc content, while elongation and impact resistance tend to decline.

Corrosion Resistance in Low and High Zinc Brass

Low zinc brass typically contains less than 15% zinc, offering superior corrosion resistance in marine and acidic environments compared to high zinc brass, which often exceeds 20% zinc and is more prone to dezincification and stress corrosion cracking. The lower zinc content in low zinc brass minimizes galvanic corrosion, making it ideal for plumbing and electrical applications where long-term durability is critical. High zinc brass enhances mechanical strength but requires protective coatings or treatments to mitigate its vulnerability to corrosion, particularly in chloride-rich atmospheres.

Workability and Machinability Differences

Low zinc brass, typically containing less than 35% zinc, offers superior workability due to its softer and more malleable nature, making it ideal for intricate shaping and forming processes. In contrast, high zinc brass, with zinc content exceeding 35%, exhibits enhanced machinability, allowing faster cutting speeds and better tool life, but it is less ductile and more prone to cracking during forming. These differences impact material selection based on whether precision machining or complex fabrication is prioritized in manufacturing.

Color and Aesthetic Variations

Low zinc brass typically exhibits a richer, deeper golden hue due to its higher copper content, creating a warm and classic appearance ideal for decorative applications. High zinc brass, containing a greater zinc percentage, tends to have a paler, more yellowish color with a slight sheen, offering a brighter and more modern aesthetic. These color variations directly influence design choices in jewelry, musical instruments, and architectural elements where visual impact is crucial.

Typical Applications of Low Zinc Brass

Low zinc brass, typically containing less than 15% zinc, is favored for applications requiring excellent corrosion resistance and good machinability, such as plumbing fittings, marine hardware, and electrical components. Its lower zinc content enhances resistance to dezincification, making it ideal for potable water systems and outdoor environments. Manufacturers also use low zinc brass in decorative items where durability and aesthetic appeal are essential.

Common Uses for High Zinc Brass

High zinc brass, containing typically 30-40% zinc, is widely used in manufacturing automotive parts, electrical connectors, and plumbing fittings due to its superior strength and corrosion resistance compared to low zinc brass. Its durability and machinability make it ideal for producing gears, valves, and fasteners in industrial applications. High zinc brass also finds common use in architectural hardware and musical instruments, benefiting from its enhanced hardness and polished finish.

Cost Implications of Zinc Content in Brass

Low zinc brass typically contains less than 20% zinc, resulting in lower material costs compared to high zinc brass, which can exceed 37% zinc content. The higher zinc concentration in high zinc brass increases its strength and machinability but also raises production expenses due to the cost of zinc and more complex processing requirements. Manufacturers often balance these cost implications against performance needs, choosing low zinc brass for budget-conscious applications and high zinc brass when enhanced mechanical properties justify the additional investment.

Choosing the Right Brass Alloy: Factors to Consider

Low zinc brass, typically containing up to 35% zinc, offers superior corrosion resistance and is ideal for applications requiring enhanced machinability and strength. High zinc brass, with zinc content exceeding 35%, provides increased hardness and tensile strength but may sacrifice corrosion resistance in harsh environments. Selecting the right brass alloy depends on factors such as mechanical performance requirements, environmental exposure, and cost efficiency to ensure optimal durability and functionality.

Low Zinc Brass vs High Zinc Brass Infographic

materialdif.com

materialdif.com