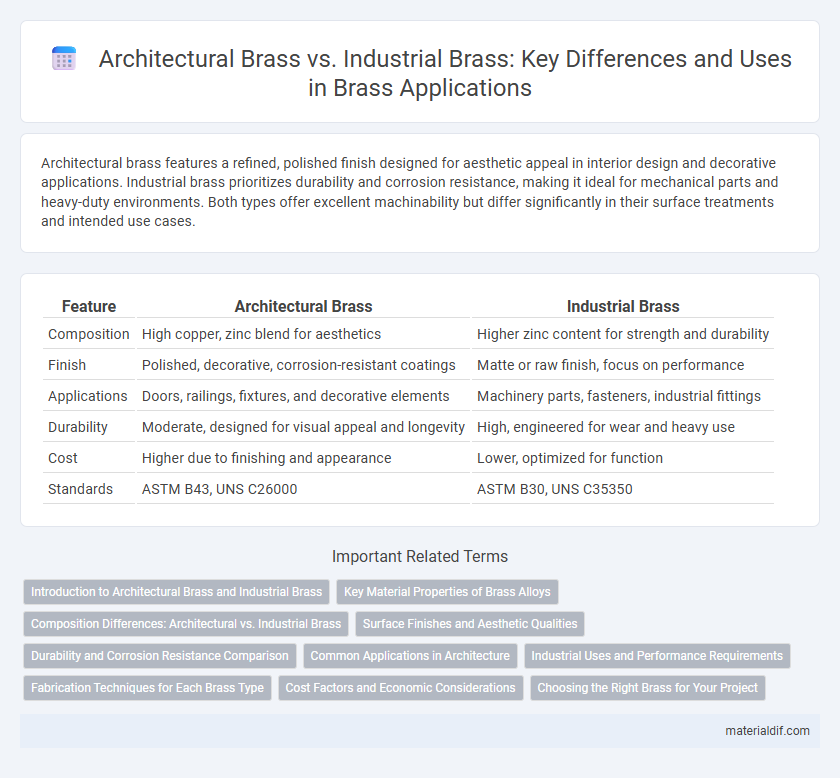

Architectural brass features a refined, polished finish designed for aesthetic appeal in interior design and decorative applications. Industrial brass prioritizes durability and corrosion resistance, making it ideal for mechanical parts and heavy-duty environments. Both types offer excellent machinability but differ significantly in their surface treatments and intended use cases.

Table of Comparison

| Feature | Architectural Brass | Industrial Brass |

|---|---|---|

| Composition | High copper, zinc blend for aesthetics | Higher zinc content for strength and durability |

| Finish | Polished, decorative, corrosion-resistant coatings | Matte or raw finish, focus on performance |

| Applications | Doors, railings, fixtures, and decorative elements | Machinery parts, fasteners, industrial fittings |

| Durability | Moderate, designed for visual appeal and longevity | High, engineered for wear and heavy use |

| Cost | Higher due to finishing and appearance | Lower, optimized for function |

| Standards | ASTM B43, UNS C26000 | ASTM B30, UNS C35350 |

Introduction to Architectural Brass and Industrial Brass

Architectural brass is an alloy specifically designed for aesthetic applications in building interiors and exteriors, valued for its corrosion resistance, malleability, and attractive golden sheen. Industrial brass, by contrast, prioritizes mechanical strength and durability for manufacturing components such as valves, gears, and fittings where resistance to wear and pressure is critical. Both types of brass share a copper-zinc composition but differ in alloying elements and processing to meet distinct functional demands in architectural and industrial sectors.

Key Material Properties of Brass Alloys

Architectural brass alloys exhibit enhanced corrosion resistance and aesthetic appeal, achieved through higher copper content and trace elements like zinc and tin, making them ideal for decorative applications. Industrial brass alloys prioritize mechanical strength and machinability, often incorporating lead or aluminum to withstand heavy wear and high-stress environments. Both types leverage brass's natural antimicrobial properties and thermal conductivity, but their tailored compositions define their suitability for architectural versus industrial use.

Composition Differences: Architectural vs. Industrial Brass

Architectural brass typically contains a higher percentage of copper, around 60-70%, combined with zinc and small amounts of lead to enhance machinability and corrosion resistance, making it ideal for decorative and structural applications. Industrial brass often features a higher zinc content, up to 40%, and may include other alloying elements such as tin or iron to improve strength and wear resistance for heavy-duty equipment and manufacturing environments. The distinct composition differences directly affect their mechanical properties, corrosion resistance, and suitability for specific uses in architectural versus industrial settings.

Surface Finishes and Aesthetic Qualities

Architectural brass features meticulously polished and lacquered surface finishes that enhance its warm, golden hue and offer resistance to tarnishing, making it ideal for decorative applications and high-visibility installations. Industrial brass typically has a more utilitarian surface finish, such as matte or brushed textures, prioritizing durability and corrosion resistance over visual appeal in harsh environments. The aesthetic qualities of architectural brass emphasize elegance and luxury, while industrial brass balances functionality with ruggedness in demanding mechanical or structural contexts.

Durability and Corrosion Resistance Comparison

Architectural brass is engineered with enhanced corrosion resistance and durability to withstand outdoor and decorative applications, often incorporating alloys such as copper-zinc with small amounts of lead for machinability and improved patina formation. Industrial brass prioritizes strength and wear resistance for mechanical components, typically containing lower levels of zinc and additional metals like tin or iron to boost hardness and reduce corrosion in harsh industrial environments. Both types exhibit excellent resistance to corrosion, but architectural brass excels in aesthetic longevity, while industrial brass is optimized for mechanical durability under stress.

Common Applications in Architecture

Architectural brass is commonly used in decorative elements such as door hardware, handrails, and lighting fixtures due to its aesthetic appeal and corrosion resistance. Industrial brass, while durable, is typically reserved for mechanical components like valves, gears, and bearings where functionality is prioritized over appearance. The choice between architectural and industrial brass depends on the balance between visual design requirements and mechanical performance in building projects.

Industrial Uses and Performance Requirements

Industrial brass is engineered to withstand rigorous mechanical stress, high temperatures, and corrosion in demanding environments such as machinery components, valves, and electrical fittings. Its high tensile strength, excellent machinability, and resistance to dezincification make it ideal for heavy-duty industrial applications. Compared to architectural brass, industrial brass prioritizes durability and performance under harsh conditions over aesthetic appeal.

Fabrication Techniques for Each Brass Type

Architectural brass often undergoes precise machining, polishing, and finishing processes such as anodizing or powder coating to enhance its aesthetic appeal and corrosion resistance, suitable for decorative applications. Industrial brass fabrication emphasizes robustness with techniques like forging, extrusion, and casting that prioritize strength and durability for mechanical parts and equipment components. Each brass type's fabrication methods align with its intended use, balancing appearance and performance requirements.

Cost Factors and Economic Considerations

Architectural brass generally incurs higher costs due to its superior finish, corrosion resistance, and aesthetic appeal tailored for decorative purposes, while industrial brass prioritizes functionality and durability, resulting in more economical raw material and production expenses. The economic considerations favor architectural brass in applications demanding visual impact and long-term maintenance savings, whereas industrial brass offers cost efficiency for mass production and mechanical uses. Evaluating total ownership cost and specific use-case requirements determines the optimal brass type selection between architectural and industrial grades.

Choosing the Right Brass for Your Project

Architectural brass is specifically designed for aesthetic appeal and corrosion resistance, making it ideal for decorative elements, fixtures, and interior design projects. Industrial brass offers higher mechanical strength and durability, suited for heavy-duty applications such as machinery components and plumbing systems. Selecting the right brass depends on balancing visual requirements with functional performance, considering factors like exposure environment, load demands, and maintenance needs.

Architectural Brass vs Industrial Brass Infographic

materialdif.com

materialdif.com