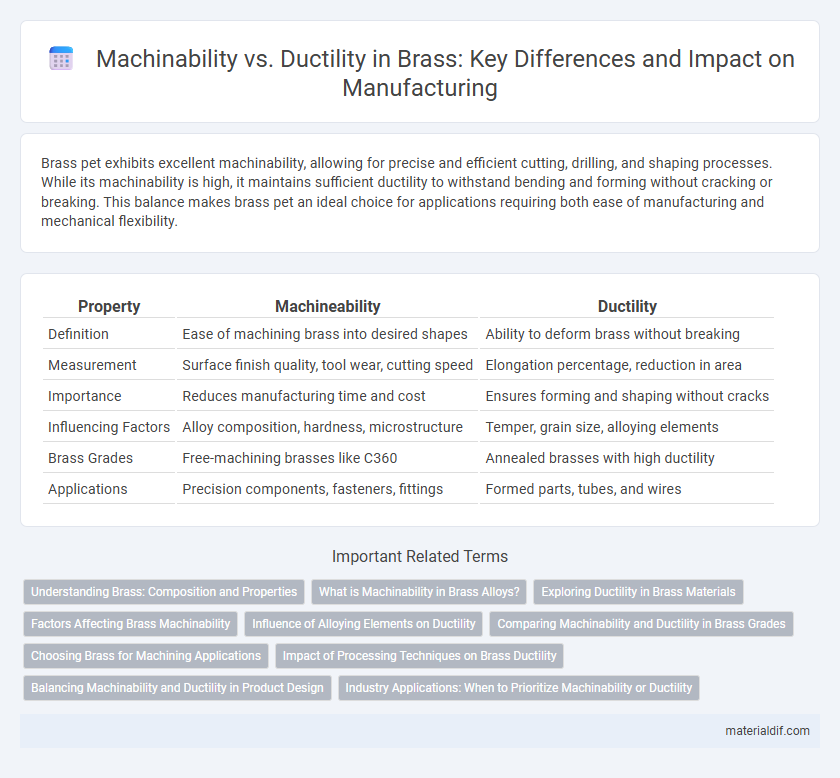

Brass pet exhibits excellent machinability, allowing for precise and efficient cutting, drilling, and shaping processes. While its machinability is high, it maintains sufficient ductility to withstand bending and forming without cracking or breaking. This balance makes brass pet an ideal choice for applications requiring both ease of manufacturing and mechanical flexibility.

Table of Comparison

| Property | Machineability | Ductility |

|---|---|---|

| Definition | Ease of machining brass into desired shapes | Ability to deform brass without breaking |

| Measurement | Surface finish quality, tool wear, cutting speed | Elongation percentage, reduction in area |

| Importance | Reduces manufacturing time and cost | Ensures forming and shaping without cracks |

| Influencing Factors | Alloy composition, hardness, microstructure | Temper, grain size, alloying elements |

| Brass Grades | Free-machining brasses like C360 | Annealed brasses with high ductility |

| Applications | Precision components, fasteners, fittings | Formed parts, tubes, and wires |

Understanding Brass: Composition and Properties

Brass, an alloy primarily composed of copper and zinc, exhibits excellent machinability due to its low work hardening rate and uniform microstructure, enabling precise cutting and shaping. Its ductility varies depending on zinc content, with lower zinc percentages enhancing malleability, making it suitable for forming and bending applications. Understanding the balance between machinability and ductility in brass is essential for selecting the appropriate alloy composition for specific industrial and manufacturing processes.

What is Machinability in Brass Alloys?

Machinability in brass alloys refers to the ease with which the material can be cut, shaped, or drilled using machining tools while maintaining tool life and surface finish quality. It is influenced by alloy composition, hardness, and microstructure, with free-machining brasses containing lead or silicon additives exhibiting superior machinability due to chip breaking and reduced tool wear. High machinability brass alloys balance performance properties like strength and corrosion resistance with efficient manufacturing processes, critical for applications in plumbing, electrical connectors, and precision components.

Exploring Ductility in Brass Materials

Brass exhibits excellent ductility, allowing it to be easily formed into complex shapes without cracking, which is crucial for applications requiring detailed machining. Its high ductility results from its copper-zinc alloy composition, where the zinc content alters mechanical properties while maintaining sufficient plastic deformation capability. This balance between machineability and ductility makes brass an optimal choice for manufacturing components that require both precision machining and durable, flexible performance.

Factors Affecting Brass Machinability

Brass machinability depends on factors such as alloy composition, microstructure, and lubrication during cutting processes. Higher lead content and fine grain size enhance machinability by reducing tool wear and improving chip formation, while excessive hardness and impurities decrease it. Optimal machining conditions involve balancing ductility to prevent brittleness with sufficient hardness to maintain shape and surface finish quality.

Influence of Alloying Elements on Ductility

Alloying elements such as zinc, lead, and tin significantly influence the ductility of brass by altering its microstructure and grain boundaries. Increasing zinc content typically enhances strength but reduces ductility, while small additions of lead improve machinability without severely compromising ductility due to localized lubrication effects. Elemental control in brass compositions enables a balance between machinability and ductility tailored for specific industrial applications.

Comparing Machinability and Ductility in Brass Grades

High machinability in brass grades like C36000 allows faster cutting and longer tool life, making them ideal for complex components. In contrast, ductile brass grades such as C26000 offer superior formability and elongation but reduced machinability due to their tougher microstructure. Selecting the appropriate brass grade balances machining efficiency and mechanical flexibility based on application-specific requirements.

Choosing Brass for Machining Applications

Brass offers superior machinability due to its low friction and excellent chip formation, making it ideal for precision machining applications. Its moderate ductility allows for shaping without cracking, ensuring both ease of cutting and structural integrity during fabrication. Selecting brass alloys like free-machining brasses (e.g., UNS C36000) optimizes production efficiency and reduces tool wear in machining processes.

Impact of Processing Techniques on Brass Ductility

Processing techniques such as annealing and cold rolling significantly influence brass ductility by altering its microstructure and dislocation density. Annealing restores ductility by recrystallizing grains and reducing internal stresses, while cold rolling increases strength but decreases ductility due to strain hardening. Optimizing these processes allows control over brass's balance between machinability and ductility, enhancing performance in various industrial applications.

Balancing Machinability and Ductility in Product Design

Balancing machinability and ductility in brass alloys requires careful selection of composition and processing methods to optimize both ease of machining and mechanical performance. High machinability brass typically contains lead or bismuth additives, enhancing chip formation and tool life but potentially reducing ductility and corrosion resistance. Designers must tailor alloy grades to achieve a compromise that maintains sufficient ductility for forming and durability while maximizing machining efficiency and surface finish quality.

Industry Applications: When to Prioritize Machinability or Ductility

In industrial applications of brass, machinability is prioritized when precision components like fittings, valves, and intricate hardware parts require efficient cutting and shaping without excessive tool wear. Ductility becomes crucial for applications involving complex forming processes such as deep drawing or wire production, where the material must sustain significant deformation without failure. Balancing machinability and ductility depends on specific manufacturing needs, with high machinability grades favored for rapid machining and high ductility grades chosen for extensive forming and shaping in industries like automotive and plumbing.

Machineability vs Ductility Infographic

materialdif.com

materialdif.com