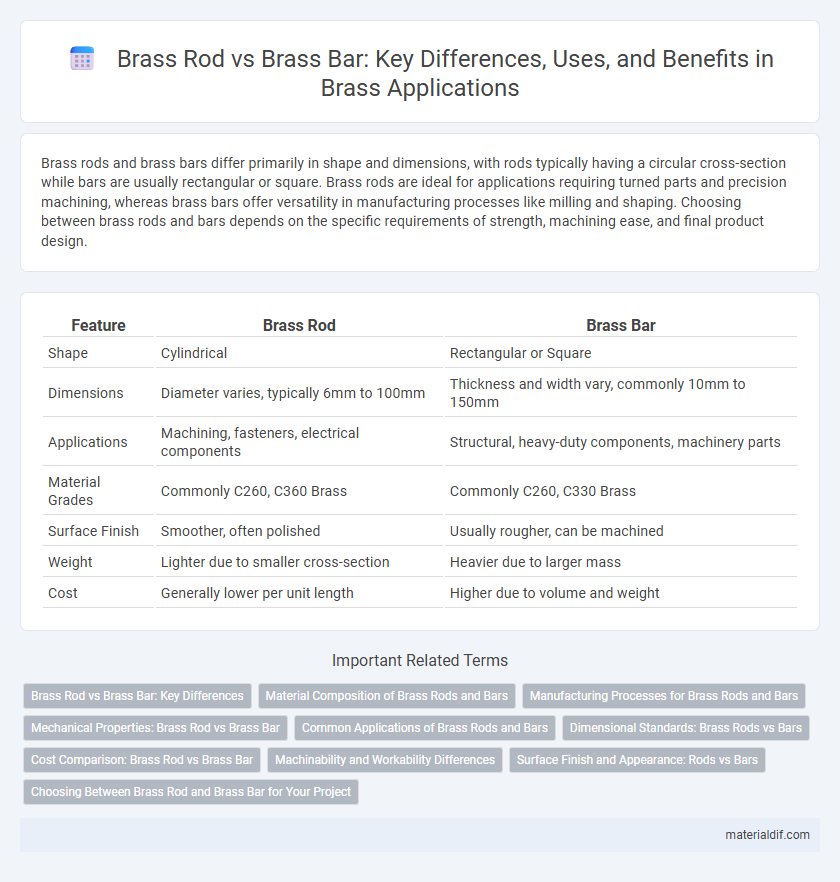

Brass rods and brass bars differ primarily in shape and dimensions, with rods typically having a circular cross-section while bars are usually rectangular or square. Brass rods are ideal for applications requiring turned parts and precision machining, whereas brass bars offer versatility in manufacturing processes like milling and shaping. Choosing between brass rods and bars depends on the specific requirements of strength, machining ease, and final product design.

Table of Comparison

| Feature | Brass Rod | Brass Bar |

|---|---|---|

| Shape | Cylindrical | Rectangular or Square |

| Dimensions | Diameter varies, typically 6mm to 100mm | Thickness and width vary, commonly 10mm to 150mm |

| Applications | Machining, fasteners, electrical components | Structural, heavy-duty components, machinery parts |

| Material Grades | Commonly C260, C360 Brass | Commonly C260, C330 Brass |

| Surface Finish | Smoother, often polished | Usually rougher, can be machined |

| Weight | Lighter due to smaller cross-section | Heavier due to larger mass |

| Cost | Generally lower per unit length | Higher due to volume and weight |

Brass Rod vs Brass Bar: Key Differences

Brass rod and brass bar differ primarily in their shape and application, with rods typically featuring a round cross-section and bars available in square or rectangular profiles. Brass rods are commonly used in machining and precision components due to their consistent diameter, while brass bars provide greater surface area for structural and industrial applications. The choice between brass rod and brass bar depends on the specific mechanical properties, dimensional tolerances, and end-use requirements.

Material Composition of Brass Rods and Bars

Brass rods and bars predominantly consist of copper and zinc, with variations in the zinc content influencing their mechanical properties and corrosion resistance. Brass rods typically have higher precision in alloy composition, ensuring uniformity for applications requiring tight tolerances, while brass bars may feature a broader range of copper and zinc ratios to accommodate diverse industrial uses. Specific additives such as lead, tin, or iron can be incorporated in both rods and bars to enhance machinability, strength, or wear resistance depending on the grade and intended application.

Manufacturing Processes for Brass Rods and Bars

Brass rods are typically produced through hot extrusion, where heated brass billets are forced through a die to create long, uniform cylindrical shapes, ensuring precise diameters and smooth surfaces. Brass bars are often manufactured by hot rolling or continuous casting, allowing the material to be shaped into rectangular or square cross-sections with consistent dimensions. Cold drawing processes can be applied to both rods and bars to improve mechanical properties, surface finish, and dimensional accuracy.

Mechanical Properties: Brass Rod vs Brass Bar

Brass rods typically exhibit higher tensile strength and better machinability compared to brass bars due to their controlled manufacturing process and fine grain structure. Brass bars, often used in structural applications, provide greater dimensional stability and resistance to deformation under heavy loads. Both brass rods and bars offer excellent corrosion resistance and good thermal conductivity, but rods are preferred when precision and uniform mechanical properties are critical.

Common Applications of Brass Rods and Bars

Brass rods and bars are integral components in manufacturing, with rods commonly used in precision machining for automotive parts, electrical connectors, and musical instruments due to their uniform diameter and machinability. Brass bars, characterized by their larger rectangular or square cross-sections, find applications in structural components, marine hardware, and decorative architectural fittings where strength and aesthetic appeal are paramount. Both materials leverage brass's corrosion resistance and thermal conductivity, making them essential in plumbing, electrical, and industrial equipment industries.

Dimensional Standards: Brass Rods vs Bars

Brass rods typically adhere to precise dimensional standards defined by diameters ranging from 1/8 inch to 8 inches for seamless applications, ensuring uniformity in machining processes. Brass bars are generally produced in rectangular or square cross-sections with dimensional tolerances standardized according to ASTM B16 or B124 specifications for hot-rolled and extruded shapes. Understanding these dimensional standards is critical for selecting the appropriate brass stock for manufacturing components requiring strict geometric consistency.

Cost Comparison: Brass Rod vs Brass Bar

Brass rods generally cost more per unit weight than brass bars due to their specialized manufacturing processes and applications requiring tighter dimensional tolerances. Brass bars, with their larger cross-sectional area and broader production methods, offer a more economical option for bulk material needs. For projects prioritizing cost efficiency over precision, brass bars present a lower-cost alternative compared to brass rods.

Machinability and Workability Differences

Brass rods typically offer superior machinability compared to brass bars due to their uniform grain structure and precise manufacturing tolerances, allowing for smoother cutting and reduced tool wear. Brass bars, being larger and less refined, may present more variability in workability, often requiring additional processing to achieve desired shapes. The enhanced machinability of brass rods makes them preferable for applications demanding intricate detailing and tight dimensional accuracy.

Surface Finish and Appearance: Rods vs Bars

Brass rods typically feature a smooth, uniform surface finish ideal for precision machining and decorative applications, offering consistent appearance and minimal surface imperfections. In contrast, brass bars often exhibit a coarser surface finish with visible milling marks, making them more suitable for structural uses where appearance is less critical. The choice between rods and bars depends largely on the desired surface quality and final aesthetic requirements in brass components.

Choosing Between Brass Rod and Brass Bar for Your Project

Choosing between brass rod and brass bar depends on the specific requirements of your project, such as shape, size, and machining needs. Brass rods are typically round and ideal for precision components, while brass bars offer a variety of cross-sectional shapes, including square and rectangular, suited for structural applications. Evaluating the desired mechanical properties and fabrication methods ensures the optimal choice for durability and performance.

Brass Rod vs Brass Bar Infographic

materialdif.com

materialdif.com